About 2 years ago, Mark Gordon shared some preliminary research he’d conducted with the Applied Ballistics team. They thought the results were interesting and suggested he get in touch with me to collaborate on how to further collect data, and eventually share those findings with the shooting community on Precision Rifle Blog. So here we are! I’m super-excited to share this with you guys!

So, Who Did This Research?

Since Mark conducted the research and collected this data, maybe we should start with “Who is Mark Gordon?” Mark is the owner of Short Action Customs (SAC), and he is an incessant tinkerer. “Our business has been founded with the principal that everything must be challenged and improved upon,” Mark explained. “Techniques, tooling, fixtures and execution can all be refined to the point of perfection.”

Mark’s background includes serving in the U.S. Marine Corps from 2001-2006 as a 6113 CH-53 flight line mechanic with 3 overseas tours. When you’re a helicopter mechanic, “good enough” isn’t in your vocabulary. After an honorable discharge, Mark made the conscious decision to pursue a career in gunsmithing, a craft he is clearly passionate about. That isn’t something he just “fell into” or picked up as he went. Instead, he moved to North Carolina to receive formal training and earn a degree in gunsmithing. Mark founded Short Action Customs in 2009, starting as a one-man shop. Mark’s work quickly earned him a strong reputation in the precision rifle community, and his staff and facilities have grown dramatically since that time. Today their facilities in Ohio consists of 20 acres, including an 800+ yard range with an electronic target system to test and evaluate their rifles. That also serves as a lab or proving grounds as they apply a data-driven approach to develop new products and refine processes. SAC has multiple Haas CNC machines that allows them to do just about everything in-house. SAC builds a ton of custom precision rifles. In 2019, they chambered over 500 barrels, so it’s clearly grown well beyond the small mom-and-pop shop! Mark currently serves as the CEO and is still very involved in the day-to-day operations.

Today most rifle gunsmiths are building rifles from the same parts that are made by the same companies. Mark has an internal drive to produce a better product than the gunsmiths that are simply bolting things together. He told me “I don’t want that only to be that I know in my heart it is better, but to be able to measure it and see it in hard data.” As a hardcore data-driven guy myself, Mark, you have my attention!

Mark brings an obsessive approach to optimizing every facet of the rifle system. First, he is a very sharp guy who brings a methodical and creative approach to troubleshooting issues and identifying root causes. For example, one rifle SAC built had occasional flyers. Through an exhaustive process Mark eventually found it seemed to be related to inconsistent ignition. By simply swapping the trigger, the bullets suddenly all went in the same hole. But, many gunsmiths would have stopped there – the rifle now shoots, ship it and move on! Instead, Mark bought a rail gun, rigged it up with high-speed sensors and used his electronic target system to evaluate a variety of triggers in order to understand what it was about a trigger design that caused inconsistent ignition. It wasn’t good enough to know that it worked or even have a theory as to why; he wanted to get to the bottom of it and prove it with data and a scientific process, so he could avoid that problem from ever cropping up again on a rifle with his name on it. That is a perfect example of Mark’s relentless and unconventional approach to his craft of building precision rifles. For more examples, just go to the SAC YouTube Channel and watch his videos about processes and products they’ve developed.

We shouldn’t be surprised that Mark’s analytical and deliberate approach eventually led to research on the ammo his rifles were being fed. Were there any small improvements he could make to the chambers on his rifles to improve their performance over the competition? This eventually led him to start testing bullet jump, and some of his results may seem to challenge conventional wisdom. This research has challenged me as much as anyone, but here is a quote I always try to keep in mind:

“It is the mark of an educated mind to be able to entertain a thought without accepting it.” – Aristotle

So, I ask you, dear reader, to stay open to the idea as I unpack this research, and don’t be too quick to dismiss it.

A Quick Recap

Remember the first article in this series summarized what conventional wisdom says about bullet jump, and the consensus among leading shooters and researchers was that the best precision is achieved by either seating the bullet into the lands or up to 0.020” off the lands. We also saw that leading shooters and researchers believe changing bullet jump by 0.002-0.005” can dramatically affect precision, especially when seated close to the lands. (Not sure what we mean by bullet jump or freebore? Read that article.)

Then in the last article, we discussed how quickly the lands of a barrel erode. While that is dependent on many factors, the measurements shared in the article showed an average of 0.004-0.007” of erosion every 100 rounds for popular mid-size cartridges used in precision rifle competitions.

Those two things seem to present a problem for those of us who might fire 100-200 rounds in a single match, because by the last stage our bullet jump could be 0.014” longer than it was on the first stage. If changing bullet jump by 0.002-0.005 inches can have a “dramatic” impact on precision, what will 3 times that much do?

Some of you may already be thinking you might start loading your 200 rounds of match ammo with increasing length. We just need to seat the bullet out 0.001” more every 16.67 rounds, right? Stop. Before we add yet another layer of complexity, what if we’re coming at the problem the wrong way? Knowing that we’ll be in matches that may require 100-200 rounds, maybe our priorities should be different than other shooting disciplines that are low round count or literally load their ammo at the range as they’re shooting. What if instead of looking for the one exact bullet jump that provides 100% optimal precision, we instead looked for the bullet jump that is the both forgiving in terms of bullet jump AND still provides good precision?

Also think about how this impacts those shooting match-grade factory ammo, who don’t reload. Wouldn’t they prefer to have a bullet jump that is more forgiving, since they won’t be able to manage their seating depth like a reloader could?

See where this is going? 😉 That is what led Mark Gordon to start methodically testing bullet jump, but he brought an interesting approach and his results are very interesting.

Mark’s Approach To Testing Bullet Jump

Many reloaders are familiar with Creighton Audette’s Ladder Test or Dan Newberry’s Optimal Charge Weight (OCW) methods of load development. While the theory and approach of those two methods are different, the goal of both is to find a very “pressure tolerant” or “resilient” load that is consistent and predictable even despite slight variations. The idea is that you can find a “sweet spot” when it comes to the amount of powder you use in a particular load so that minor variations from one loaded round to another would still produce similar muzzle velocities and points of impact (POI). The goal is to find the most stable/forgiving load so that bullets continue to go in the in the same hole even if there are slight variations in chamber pressure, maybe because there are a few more or less kernels of powder in the case, one primer is hotter than average, swings in ambient temperature, etc.

The Audette method basically loads up 1 round with several increments of powder charge weights, and then charts them like what is shown below:

The flat section on the chart indicates loads with stable velocity despite minor differences in powder charge weight. This test shows that loads with 69.6-70.0 gr. of Retumbo all produced very similar velocities. In this example, the ladder test would indicate 69.8 gr. as the most forgiving/consistent load.

Important point for Audette’s Ladder Test: With this test there is only a sample size of one for each charge weight. When we are looking for patterns like this, very small sample sizes may show clusters, but if we repeated the exact same test those clusters might appear somewhere else. Such a small sample size could potentially give a false sense of confidence in the results.

Dan Newberry’s Optimal Charge Weight (OCW) method has a different approach. Instead of looking for the flat section on the muzzle velocity chart, we would fire groups with incrementally different powder charges, and look for the 3 groups that have the closest average Point Of Impact (POI). The visual below shows the results for one of my OCW tests. I shot five 3-shot groups with 5 different powder charge weights, and I overlaid the center of the POI for each of the five groups on the diagram.

The POI for groups 2, 3, and 4 were all very similar, even though the charge weight was incrementally different for each. In fact, the loads for 2, 3, and 4 were 69.2, 69.5, and 69.8gr of Retumbo, which would suggest a similar load to what the ladder test indicated above.

Dan has this tip for us for the OCW method, which is especially interesting for the topic of seating depth:

“Remember, don’t get ‘bowled over’ by a tiny group which falls outside the OCW zone. You can tune any of the groups to be tiny with bullet seating depth changes. After you have determined the OCW, you may want to try seating the bullets deeper or longer in .005″ or .010″ increments to see where your particular rifle does its best. If you’re a real stickler for accuracy, ‘round robin’ test using varied seating depths, perhaps in 0.003″ increments. Look for at least two seating depth stages that hit the same POI and group tight as well. This said, I have often found that OCW recipes are so reliable that seating depth alterations often don’t seem necessary, especially for hunting cartridges.”

I appreciate Dan’s approach, and have used it many times. But, unlike hunters, many of us shoot hundreds or even thousands of rounds a year through our precision rifles. We fire more rounds in a weekend than most hunters do in a decade. Because of that, our rifle barrel wears and is constantly changing underneath us. Notice that Dan recommended testing seating depth in 0.003″ increments “if you’re a real stickler for accuracy.” Of course, I’m a stickler for accuracy! But I also know the rifling on my 6mm Creedmoor barrel is eroding by 0.006-0.007” on average every 100 rounds. So, if I find ideal bullet seating depth, it would have changed by the 0.003″ increment he’s suggesting within just 50 rounds!

Mark used a similar approach to the Audette Ladder Test and OCW method, but the goal was to not find the most forgiving powder charge weight, but the most forgiving bullet jump. He wasn’t looking for the specific bullet jump that grouped the best, but the largest window of bullet jumps that provided a similar point of impact. That means the rifle would be more consistent from the start of the match to the end of it or could shoot a particular kind of match-grade factory ammo really well for a longer period of time.

Here is how Mark performed the tests:

- Carefully measure the bullet seating depth required for the bullet to very lightly contact the lands (i.e. 0.000” jump, but not jammed into the lands). Watch my video showing Mark Gordon’s method on how to do this.

- Load up 20 identical rounds, except vary the bullet seating depth in 0.005” increments. #1 = 0.000” jump, #2 = 0.005” jump, #3 = 0.010” jump, … , #20 = 0.095” jump.

- Fire the rounds at 600 yards, recording the point of impact coordinates for each shot with an electronic targeting system and muzzle velocities with a LabRadar.

Short Action Customs primarily builds precision rifles that are purpose-built for long range work, so Mark has a long-distance range right there at his shop where they prove each rifle, which made measuring the results at distance easy. Collecting the data at long range helps eliminate the theories guys might have about groups doing one thing at 100 yards, and something else at distance. I’ll side-step that debate for now, because it’s outside the scope of this article.

Once Mark collected the data, it just came down to analyzing it, and for that he decided to primarily focus on vertical dispersion. Many competitive shooters use the amount of vertical stringing in the group at long range as the real test of a good load. Here is what one of the best reloading guides has to say about that: “The less vertical dispersion in the group, the more 10 ring is available to accommodate changes in wind and wind reading errors. That is why 1,000 yard, highpower shooters will often cite ‘elevation’ as the measure of a load, rather than overall group size … The reason is that ‘elevation’ is more of a measure of the hardware and windage is more a measure of the shooter’s wind reading ability.” – Precision Shooting Reloading Guide (Published by Precision Shooting Magazine)

Mark didn’t start off with a theory to prove, but simply wanted to uncover what worked best across multiple rifles, so he could optimize the custom rifles SAC builds. After testing a wide range of bullet jumps on a few rifles, some interesting and somewhat unexpected patterns started to appear. Over the past two years, Mark expanded his testing over a wider range of bullets and rifle configurations. I’ll be sharing his research findings in this and the next few posts.

Let’s See the Data!

Mark has collected data on a variety of bullets, but he’s compiled the most data on the Berger 105gr Hybrid, so that is where we’ll start. We’ll begin by looking at one 20 shot test in particular to understand how the data was crunched from the actual target to the charts, and then we’ll have context for what the subsequent charts represent in terms of real-world impacts at long range.

Below is a screenshot of one target, as an example. This was from the electronic target system that was placed at 600 yards and shows the exact position of each of the shots in the 20 shot string. Notice the vertical coordinate of shot #20 is highlighted, which says -3.5 inches. We’ll come back to that later.

I should mention that Mark wasn’t trying to center the group on the target, because all he really needed was the relative change from one shot to the next. You can see that shot #1 and #2 are very far apart both horizontally and vertically, then #3 is much higher than #2. To really understand what we’re analyzing here, take a minute to trace all 20 shots on the target above in order (i.e. start with #1, then go to #2, etc.), and be careful to notice how much vertical difference there is from one shot to the next. We are hoping to find at least 3 shots in a row with a similar vertical POI, which would hint towards a potential range of bullet jumps that may be more forgiving.

Mark exported the coordinate data from the electronic target system and combined it with the related muzzle velocity data from a LabRadar for each shot, into a table like the one below. You can see the Y Coordinate highlighted in the table for shot #20 matches the number highlighted on the target above. Since we had the raw coordinates for each shot, I was able to calculate the center of the entire string of 20 shots and then convert those figures over to MOA to make this less specific to one distance and easier to compare. All that data and the calculated numbers are shown in the table below.

Notice the highlighted number in the table is the Y Coordinate of the shot on the target for shot #20, which was -3.5 inches and matches the target image shown above.

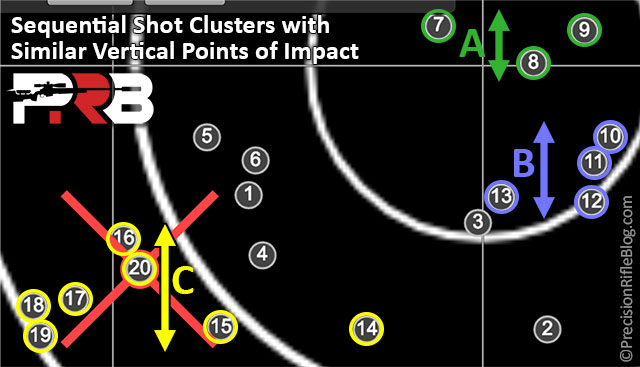

What we’re looking for on the target image is patterns where sequential shots had similar vertical points of impact. In this example, there seems to be 3 clusters of sequential shots with minimal changes in vertical POI:

- Shots 7, 8, 9 (highlighted in green)

- Shots 10, 11, 12, 13 (highlighted in blue)

- Shots 14, 15, 16, 17, 18, 19, 20 (highlighted in yellow)

While the vertical spread for shots 14-20 may appear large, remember this target was at 600 yards. The vertical extreme spread for those 6 shots in yellow was only 1.6 inches (the distance the yellow line with arrows on both ends represents), which is only 0.25 MOA in vertical – so all 3 of the highlighted clusters aren’t too shabby!

While we can visually identify the clusters on the target if we look at it for a minute or two, there is another way to visualize the data to help those clusters become more obvious, and that is to chart the numbers from the “Calculated Vertical Distance From Center of Group (MOA)” column in the table above. That is what I did for the chart below, and, similar to Audette’s Ladder Test, we are now simply looking for the flatter portions of the line. You can see the 3 distinct areas that are relatively flat compared to other parts of the line, which are equivalent to the clusters highlighted above.

We want to avoid portions of the line with large changes on the chart, because those equate to a dramatic change in terms of vertical point of impact with only a 0.005-inch change in bullet jump (which could potentially happen in 100 rounds or less). You can see steep lines between 1 to 2, 2 to 3, 4 to 5, 6 to 7, 9 to 10, and 13 to 14, and those are the areas we want to avoid. To put that in context, the POI for #2 was 2.3 inches lower than #1 at 600 yards (or -3.7 MOA). You can also see there is a small jump from shot 15 to 16. Go back and look at the target, and you can see that sure enough the POI for 16 is higher than 15. So the chart is simply representing the data from the target, and trying to make it easier to see patterns in terms of shifts in vertical POI.

Of course, all the data we’ve covered so far is from a single test, and I’m not suggesting we attempt to draw any meaningful conclusions from one test. It was only 20 shots with a sample size of only 1 shot for each bullet jump. I simply thought it was important for everyone to understand how we arrived at the visual like the chart above, and what that physically represents in terms of rounds on target at long range.

Berger 105gr Hybrid Bullet Jump Over 10 Rifle/Load Configurations

Mark has repeated the same 20 shot bullet jump test using the Berger 105gr Hybrid over 10 different rifle/load configurations. That included 5 different 6mm cartridges, and a variety of actions, stocks, and chassis. There were a couple of different brands of barrels, contours, and twist rates. Barrel lengths were primarily 26 inches, but ranged down to 23”. One configuration he tested was the exact same rifle setup, but with two distinctly different powder charge weights to see if the results followed a similar pattern if you changed the load and therefore the barrel time. Here are the complete descriptions of the rifle configurations Mark tested the Berger 105gr Hybrid in:

- 6×47 Lapua: SAC Alpha 11 action in MPA chassis with 26″ Hawk Hill Marksman 1:8″ barrel and SilencerCo Omega suppressor

- 6×47 Lapua: ARC Nucleus action in Manners PRS2 stock with 26″ Bartlein Heavy Palma 1:8″ barrel and TBAC Ultra-9 suppressor

- 6BRA: BAT TR action in MDT chassis with 26″ Bartlein Rem. Varmint +1 barrel with TBAC Ultra-9 suppressor

- 6 Dasher: Borden Mountaineer action in Manners PRS2 stock with 26″ Bartlein Heavy Palma 1:7.5″ gain twist barrel and TBAC Ultra-7 suppressor

- 6mm Creedmoor: ARC Nucleus action, 26″ Bartlein Heavy Palma 1:7.5″ barrel and TBAC Ultra-9 suppressor

- 6BRA: BAT TR action in MDT chassis with 26″ Bartlein Rem. Varmint +1 barrel

- 6×47 Lapua: ARC Nucleus action in bedded Manners PRS2 stock with Hawk Hill Rem. Varmint +1 1:8″ twist barrel and TBAC Ultra-338 suppressor (loaded to the kernel with exactly 39.2 grains)

- 6×47 Lapua: ARC Nucleus action in bedded Manners PRS2 stock with Hawk Hill Rem. Varmint +1 1:8″ twist barrel and TBAC Ultra-338 suppressor (loaded to the kernel with exactly 39.8 grains)

- 6×47 Lapua: SAC Alpha 11 action in bedded Manners T6A stock with 23″ Hawk Hill 1:7.5″ barrel and TBAC Ultra-338 suppressor

- 6BRA: BAT TR action in MDT chassis with 25″ Bartlein Rem. Varmint +1 1:8″ barrel and TBAC Ultra-338 suppressor

Now let’s get to the real data! Below is the chart representing all the bullet jump data collected over those 10 different rifle/load configurations. It is the same exact kind of data and visualization as the last example, except it isn’t just for one test string but all 10 of the rifle configurations described above overlaid on a single chart. The chart includes 200 data points based on 200 Berger 105 gr. Hybrid bullets fired for record through the various rifles.

While the chart above may look like a jumbled mess, there actually seems to be pattern across all 10 configurations. I tried to highlight the rough trendline over the data points below to make the pattern more apparent.

You can see the gray area is widest on the left side of the chart and it narrows as you move to the right and then may start to open back out slightly on the extreme right. The tightest area appears to be around 0.070 to 0.080” of bullet jump. That means over all 10 rifle/load configurations, the vertical extreme spread appears to be the tightest at 0.070 to 0.080” of bullet jump.

Another interesting thing about the chart above is it appears to be saying that when you have minimal bullet jump (0.000-0.010), that is where it appears to be least forgiving in terms of changes in bullet jump. You can tell that by the widest area of gray on the left of the chart. That means if you start off with 0.000” of bullet jump, after you’ve fired 100 rounds and the throat has eroded by 0.005”, and therefore you’re jumping 0.005”, you may very likely experience some vertical stringing, and in some cases it looks significant.

At least based on this data, there seems to be evidence to suggest the Berger 105gr Hybrid may “prefer” a jump around 0.070 to 0.080”, at least that might be the most forgiving range of bullet jumps that provide consistent vertical points of impact across the variety of rifles tested.

Average Vertical Extreme Spread Over 0.010” Range of Bullet Jumps

Let’s slice the data another way and look at a visual that illustrates the crux of what we’re trying to find. We looked across all 10 rifle/load configurations shooting the Berger 105gr Hybrid and calculated the vertical extreme spread over a rolling window of 3 sequential shots. Each column represents a bullet jump range of 0.010 inches, which is approximately what you’d expect the lands to erode over 200 rounds for popular precision rifle cartridges. For example, the first column on the left represents 3 incremental bullet jumps: 0.000, 0.005, and 0.010. I calculated the vertical extreme spread over those 3 bullet jumps for each configuration, and then averaged those values across all 10 rifle/load configurations so we could see over-arching trends.

The overall pattern appears roughly similar to the one before, with the left side of the chart larger than the right. However, we now see a spike at 0.040-0.050” of bullet jump, which didn’t stick out before. But, if we look back at the line chart that showed all the data, you can see in the window of bullet jumps from 0.040” to 0.050” there are several steep lines. Some lines spike up, others nose-dive down – but all of that collectively tells us there is a lot of erratic change in vertical POI in that window of bullet jumps for the 105 Hybrid for multiple rifle configurations tested.

So what does all this mean? Let’s say we started a two-day match with 200 rounds of loaded ammo with exactly 0.040” of bullet jump. By the end of the match the lands may have eroded by 0.010” over those 200 rounds, meaning our bullets would be jumping 0.050” before they contacted the rifling. All of the steep lines in that window from 0.040-0.050” means we could experience significant vertical shift through the match. Some of those lines indicate a relative change in vertical up to 0.6 MOA, even with just 0.005” difference in bullet jump! If a target is 1 MOA tall, then holding and breaking the shot perfectly dead center leaves 0.5 MOA on either side – so a shift of 0.6 MOA in one direction would result in a miss.

Now that we understand where the spike in the middle came from, let’s take another look at that chart:

What we’re really looking for is the shortest columns, which indicate minimal vertical stringing over a window of 0.010” of bullet jumps. You can see 0.065-0.075” appears to be the best. If we loaded our ammo to have a bullet jump of 0.065”, by the end of a 2 day match where we fired 200 rounds and our lands eroded by around 0.010”, our bullet jump would be closer to 0.075”. According to this data, the vertical POI would have likely remained very similar through that entire range of jumps. The average vertical extreme spread over that 0.010″ window of bullet jumps was only 0.23 MOA at 600 yards over all 10 rifle configurations.

Average Vertical Extreme Spread Over 0.020” Range of Bullet Jumps

The last chart looked at the vertical POI shift over 3 sequential bullet jumps, which equated to a range of 0.010” of bullet jumps. Now let’s widen that window a little more to 5 sequential bullet jumps, to see if there is still a similar pattern. This equates to a range of bullet jumps that spans 0.020”, which would be about what you would expect to happen over 400-500 rounds in popular mid-sized cartridges used in precision rifle matches.

The pattern over the 0.020” wide bullet jumps is roughly similar to the the 0.010” window we looked at before, with the POI shift appearing larger on the left side of the chart, and again smaller on the right side of the chart. Here the most forgiving range of bullet jumps in terms of vertical POI shift appears to be 0.065-0.085”, which had an average extreme spread of just 0.33 MOA over that entire range of jumps for all 10 rifle/load configurations tested.

What Does This Mean for Shooters Using Factory Ammo?

Now let’s think about what this means if you’re one of the many shooters who uses factory ammo instead of reloading. Since we’re talking about 6mm bullets, let’s say you chose to run Berger’s 6mm Creedmoor 105gr Hybrid match-grade ammo. Conventional wisdom would say you want minimal bullet jump, so you might decide to optimize your chamber’s freebore so that you’d have 0.020” of bullet jump for that loaded round from Berger. By the time you’d fired 500-600 rounds, your lands would likely have eroded by around 0.030” and through that you’d have crossed through the portion of 0.040-0.050” of bullet jumps that showed the dramatic changes in POI shift. If you aren’t reloading, you can’t simply adjust your seating depth to avoid it. What seems to be more ideal, at least based on this data, would be to start with a bullet jump around 0.065” for that loaded round and as the throat erodes and the bullet jump extended further and further you wouldn’t experience as wild of swings in POI shift. That means the rifle could provide really good performance over a longer period, even if you were using factory ammo and never adjusted your seating depth.

That is a huge part of the reason Mark started this research. Remember, he was on a mission to try to optimize every facet of the custom rifles SAC builds so they’d outperform the competition – and this research seems to provide actionable insight. Of course, Mark could have kept this info to himself and considered it a competitive advantage, but I appreciate that he was willing to share it so all the rest of us could learn from it. It certainly paints a clear picture of the data-driven research and thorough optimization the team at Short Action Customs are doing behind the scenes for their customers – which includes way more than just bullet jump!

Are These Results Statistically Significant?

As Mark began to share his preliminary findings with friends in the shooting industry, a couple of people had concerns about how repeatable these tests were or how much confidence they could have in the results. Of course, from Mark’s perspective, it wasn’t like he was just trying to promote a theory. He clearly doesn’t have anything to gain by sharing this info. So he was just as interested in learning whether these patterns were random or if there might really be something here.

So, a couple of months ago Mark asked a professional statistician to analyze this data he’d collected for the 105gr Hybrid. After doing calculations and looking at the data a few different ways, the statistician’s professional opinion was that “statistically significant conclusions are appropriate.” He calculated p-values less than 0.05 with two different approaches, meaning there is strong evidence that the patterns aren’t random. The statistician was careful to add, “Extrapolations to other tests, bullet type and environmental conditions must be made with caution by the subject matter expert.” That means we shouldn’t assume these results for the 105 Hybrid represent how other bullets might behave, which is an important point.

Mark’s Theory from His Test Data

The next post will share more data on other bullets Mark has tested, but what he seems to have uncovered in his testing so far is that each bullet may have different “sweet spots” for the most forgiving bullet jump. After looking at data like this for almost two years, Mark has come to believe that each bullet design has a specific sweet spot or ideal bullet jump that will likely perform well across a variety of rifle platforms and cartridges. For the 105gr Hybrid that is apparently around 0.070” of bullet jump, as we saw in this post. Each bullet seems to have a pattern and a specific window of bullet jumps where they tend to group consistently across multiple rifle platforms, but what range of jump distances that is may vary from one bullet to another.

Support from Other Shooters & Industry Pros

Scott Satterlee

At SHOT Show this year I was having a conversation with Scott Satterlee, a top-ranked PRS & NRL competitor and Green Beret Veteran who served 26 years in Special Operations Command (learn more about Scott). Scott was showing me some of the new Defiance actions and we started talking ammo. At one point, I asked Scott about bullet jump and he stared at me for a minute and clearly hesitated before he said, “Okay, what I’m about to tell you may sound crazy, but stay with me …” and then he went on to explain that he had started using much longer bullet jumps than conventional wisdom might suggest. I said, “Really? Tell me more about that.” 😉

Scott seemed somewhat guarded as he shared, which I remember thinking was unusual, but it was likely because of the reaction he’d received from other shooters when he tried to share this before. In general, we can be a pretty stubborn group that isn’t open to new ideas, so I bet he’d seen reactions where people either clearly dismissed the idea or thought he’d lost his marbles! Mark and I had already had many conversations about this research, so I was definitely tracking with Scott.

Within an hour of that conversation with Scott, I met up with Mark to look over all this data together, and collaborate on how we’d publish all this information. Afterward, Mark and I went back and had a more extended conversation with Scott to hear more specifics about what he’d found in his own testing.

Scott said he’d been experimenting with longer bullet jumps for around 18 months, not long after Mark had shared some of his early findings with him. Scott started by varying the bullet jump of his competition load that he uses in his 6mm Creedmoor to see what produced the smallest vertical spread at 800-1000 yards. Scott said the more he jumped the bullet, the more consistent it seemed to become – which made him wonder how far it went. Lucky for us, Scott shoots so many rounds that he changes barrels almost as often as he changes underwear, so he had already tried a few different chamber dimensions with extended freebore to be able to test further and further jumps. While Mark had only tested bullet jumps out to 0.095”, Scott had tried all the way up to 0.350” freebore in his 6mm Creedmoor (compared to 0.183” SAAMI spec), which meant the bullet was jumping almost 1/4 inch (0.250”)! He said he even used a rifle/load with that 0.250″ bullet jump in a match and still finished in the top 10! Obviously it seemed to work!

Scott is now on his 5th barrel since he’s been experimenting with longer bullet jumps and said, “This isn’t something that I’m still wondering if it’s true or not. After 5 barrels, I know it’s real. There is a real improvement and benefit here.”

Scott reloads his own ammo for practice, but typically competes in matches with PRIME 6mm Creedmoor Match Ammo loaded with Nosler 115gr RDF bullets. After trying a huge range of bullet jumps, Scott found 0.120-0.150” of bullet jump to be ideal for that PRIME ammo. To get that jump, Scott is now using a custom reamer to chamber his 6mm Creedmoor, which has 0.060” more freebore than the SAAMI freebore spec for that cartridge.

Scott shared that he’d had conversations with some of the most respected gunsmiths in the nation, and a couple of them also believed in the merit of extended bullet jumps – especially when it comes to magnum cartridges. He mentioned that one gunsmith uses 0.400” of freebore in his 7mm SAUM chambers. Scott believed there could be a correlation between the size of the caliber and possibly even the case capacity, and the bigger those were the more you might benefit from extended bullet jump.

Before my last post on barrel erosion, I reached out to Scott to ask him what he was seeing on his 6mm Creedmoor barrels. I respect his opinion and knew he shot out a few barrels every year. Here is what he told me:

“I haven’t measured my throat erosion, because it simply doesn’t matter anymore. I haven’t had to change my Nosler 115 RDF load in the 6 CM in 18 months.” – Scott Satterlee

Aaron Hipp

Aaron Hipp is another pro-level precision rifle shooter, with multiple top 10 finishes in national-level competitions. Mark Gordon had shown Aaron some of his preliminary data early on in his testing. Mark told me that Aaron started off as a skeptic, because he was an adamant believer that a bullet jump 0.018” always provided the best performance. With some persistence, Mark said he eventually convinced Aaron to test it out for himself. Today Aaron is also running longer bullet jumps. In fact, below is one of his Instagram posts showing the results of one of his bullet jump tests, which is similar to Mark’s method. Instead of using the electronic target system, he basically shoots along a plumb line with a different point of aim for each bullet jump. Then he looks for patterns where his vertical POI was similar across a range of bullet jumps.

I feel compelled to note here that, like I mentioned for the Audette Ladder Test, a test like the one above only contains a sample size of one shot for each bullet jump. When we look for patterns like this, very small sample sizes may potentially show clusters, but if we repeated the same exact test those clusters may appear somewhere else. Such a small sample size could potentially give a false sense of confidence in the results, so I’d recommend running through a test like this multiple times to confirm the patterns you’re seeing persist across larger sample sizes.

Caylen Wojcik

I also recently read an article in Guns & Ammo written by Caylen Wojcik, another pro-level PRS shooter. In that article, Caylen was sharing about a new 7mm SAUM rifle he built. It was a really good article, where he shared the load development and all the specs. Caylen not only mentioned that he tested different bullet jumps, but he actually found that a jump beyond the conventional 0.020” worked best. Here is what he said:

“I don’t like to jam VLDs under any circumstance, and this chamber ended up shooting them extraordinarily well at .045-inch jump.” – Caylen Wojcik

What Is Old Is New Again?

While Mark and I were talking with Scott Satterlee at SHOT Show, Scott suggested that all of this stuff we were “discovering” might actually not be new at all, but us simply returning to what guys like Roy Weatherby and P.O. Ackley found to work best in the 1950’s. Chambers for Weatherby cartridges were designed with significant freebore, which means the bullet jump was also significant. Many today might even call it excessive – but in light of all this, it seems like it might just be a really good idea after all. We are just now catching up with them! 😉

In fact, as I was re-reading through a bunch of reloading books specifically looking for anything related to bullet jump, I came across this:

“For practical purposes, altering the bullet-seating depth might not significantly improve the accuracy of cartridges used in free-bored rifles, such as guns chambered for Weatherby cartridges. In such guns, the bullet-to-rifling jump is sufficient so that any slight seating-depth alteration is unlikely to bring about any significant improvement in accuracy, except due to a resulting variation in barrel time.” – Metallic Cartridge Handloading: Pursuit of the Perfect Cartridge

It seems like once you get to a certain distance away from the lands, slight changes in bullet jump no longer have a significant impact on precision – for better or worse. That means, as your barrel wears and the lands recede, we wouldn’t have to continually measure our distance to the lands and adjust the bullet seating depth of our ammo. In essence, the bullet jump doesn’t have to be fine-tuned – it is simply more forgiving.

The book, Handloading for Competition by Glen Zediker, also seems to corroborate that idea:

“Given the opportunity to seat up near the lands, tuning jump does matter, but when that is not possible (say when over 0.015 jump is the best we can do) then the actual amount of jump doesn’t seem to matter that much to varying group sizes. Again, best performance there is from bullet choice, and the choices run consistent with bullet design elements that tolerate jump (friendly bullets with shorter, rounder nosecones).”

Longer bullet jump and/or freebore can potentially make it easier for reloaders to manage their load over the life of a barrel, but there might be even more benefit for the guys using factory ammo. Scott Satterlee primarily uses PRIME 6mm Creedmoor 115gr RDF ammo in matches, and he regularly finishes in the top 10 in national-level competitions. Now that he is jumping that ammo over 0.100” in his 6 CM, he said he never has to worry about changing his load or tuning his seating depth. He just keeps shooting and keeps hitting targets – and remains competitive at the highest levels! While there is certainly more research that needs to be conducted before we can call this conclusive, that certainly makes it hard to argue that you can’t get the adequate performance in terms of precision with longer bullet jumps.

Up Next

In the next post, I share data Mark collected on a few other specific bullets, including:

- 6.5mm Hornady 147gr ELD-M

- 6mm Tubb 115gr DTAC

You can read that here: More Bullet Jump Research!

| Find this helpful? Appreciate the content? | ||

| Subscribe Be the first to know when the next set of results is published. Sign-up to get an email about new posts. |

or … |

Share On Facebook |

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

Bullet jump is one more variable just like powder charge.

We can experiment with a ladder test and find the sweet spot for a particular bullet with that Chambers lead angle. Closer is not always tighter groups.

That about sums it up, Brett!

The more with know, the more questions we have.

I’m waiting for Cal to start looking into quantum mechanics as it relates to PRS.

Good article!

Thanks, David. I’d love to take credit for this, but it was really Mark that not only had the idea of testing this stuff, but had the initiative and commitment to see it through. He told me a lot of this research was done at 6pm after a full day of work, he’d try to sneak in 15-30 min of testing before he went home for the day. Mark is a busy guy, like all good gunsmiths, so it really is quite the commitment to gather all this data, and do it in such a detailed and organized way.

The only part I did was try to organize the data and present it in these articles. I’d guess that probably took me 50 and 100 hours (so far), so it’s not nothing … but Mark was the one who deserves credit for this.

In fact, funny enough … as I started noticing how detailed Mark was and his OCD approach to every facet and process he applied, I actually decided to pay Short Action Customs to chamber a couple of barrels for me back in November. He had already shared a little of this data with me, but I still asked him to chamber my 6mm Creedmoor barrels with 0.100″ of freebore instead of 0.183″ SAAMI spec – so that I could seat my bullets to have minimal jump and still stay within magazine length even as I continue to seat the bullet out further over the life of the barrel. So I was obviously slow to come around to this way of thinking. Like I’ve said before, as shooters we can be pretty slow to warm up to new ideas! Obviously I wasn’t just talking about other people … I really was including myself! But, since SHOT Show I’ve spent a lot of time crunching the data and I’m a believer now too.

I will definitely test bullet seating depth at longer jumps in my rifles from now on. If for nothing else, to avoid the hassle of having to continually manage seating depth over time. I just had read all the advice from the experts about minimal jump always producing the best precision, and I guess I never questioned it. That doesn’t sound like me, honestly – and luckily Mark cured me of that blindspot! 😉

I do appreciate the encouragement. I’m glad you enjoyed the article. I think this was the most interesting thing I’ve written about in a while, and I was really excited to finally get this post in particular out.

Thanks,

Cal

Was wondering if you would allow us to post some of your articles on our FB feed? I work for this company

http://www.x-caliber.net.

https://www.facebook.com/xcaliberbarrels/

We would give you full attribution and link directly to your site.

Best Regards,

Patrick Kyle

X-Caliber Barrel & Mfg.

Hey, Patrick. I’m familiar with X-Caliber, and have even recommended your pre-fit barrels to a couple of my friends. They’ve had good luck with them too.

I’d love for you to post a link to the article on Facebook. I appreciate that!

Thanks,

Cal

What targeting system are you using? How do you like it?

Thanks !

Hey, Jeff. I asked Mark that same question. He is using the Silver Mountain G2 Target System with the upgraded 8 mic system. Mark told me it was $3,000 for the G2 unit + $1,100 to upgrade to the 8 mic system. Mark said it was a great system. I’m hoping to buy a few acres outside of town where I can shoot at least 300-400 yards (hopefully more), and I plan to get one of those setups. Looks pretty ideal. Here is a link to the product page: https://silvermountaintargetsusa.com/individual-shooters-ezp-29.html

Thanks,

Cal

That is a fantastic article Cal. Thanks for sharing. I have a new build on the way, and I plan to load develop with some of these methods. One question for you… I get the false confidence of one shot per seating depth. If you had the option, would you shoot 3-5 shots per seating depth as part of one test, or would you stay with a single shot and just perform the test multiple times? Can’t wait to see the next article. Love SAC too..

Good question, I’ve thought about that a lot and I’m not sure I can think of a way that doesn’t end up resulting in a lot of shots. I’d probably do 3 shots through the full range of jumps and then identify what segments seemed to show promise and fire another 2 rounds through those ranges to further confirm and decide the winner.

I might not start at 0.000” though … I might start a little further out, since it seems like close to the lands typically seems more erratic as the lands move on you. I know that’s a highly debated point, so you can test close if you like … but you’ll end up firing over 60 rounds that way. I might personally test 0.050” and further if you were trying to find a good load in as few of shots as possible. Nobody loves wasting barrel life on load development, after all!

Just me 2 cents, so take it for what it’s worth!

Thanks,

Cal

Great article. I’m going to back out of the lands on my 6×47 and see if I have an sweet spot where I never tested before. It would be nice to stop chasing the lands with every reload.

I totally agree, Lee! I did the same thing on my 6mm Creedmoor, but unfortunately I hadn’t used the more precise measurement method to measure the distance to my lands before I did that. Mark showed me a really good way of doing that since then, and when I used it on my 6mm Creedmoor barrels I realized how far off my original method was. I was actually still seated into the lands, even when I thought I was jumping, so I need to go back out and try again.

Here is a link to that method, in case you didn’t see it in my last post: How To Measure The Distance To The Lands On Your Barrel

Just didn’t want you to waste your time like I did last time! 😉 I’d be interested in hearing what you find.

Thanks,

Cal

Lee, give it a shot. I have been shooting the 6x47L for about 6 years now and it has been one of my favorites. My 6x47L was actually one of the first rifles that we started experimenting with bullet jump.

A classic load:

105 Berger Hybrids

.080″ Jump

39.6-40.0 gr of H4350.

As always, be careful working up in the charge weights as every rifle is different.

Thanks Cal, this may help explain why I have always achieved the smallest groups with new barrels during development and diminishing returns as rounds increase. I have usually searched from .005″ to .050″ usually landing In The .010″ to .020″ range by 100 to 125 rounds. After loading 300-500 rounds I find I never seem to get the same accuracy as when new. But I havent experimented every 100 rounds to see where the new node is either. Thanks to you and Mark for the new information.

Mike, I thought the same exact thing! I admit that for the longest time I wasn’t one of the guys who was meticulous about continuing to seat the bullet out over time. I didn’t even know how much my 6mm Creedmoor barrels were eroding, until I’d already shot out two of them. But, I thought the same thing once I started getting more educated in this, because I pretty much had the same experience as you. I would occasionally redo my load development, if/when I switched to a new bullet. My rifle would then shoot really well for a while, but eventually would open up to 0.4-0.6 MOA.

I have a couple of friends who were more anal about their load development, and they’d tend to continue to print 10-shot bug holes every time I’d see them at the range … but to do that, they were maniacal about regularly adjusting their seating depth and also periodically adding 0.1 gr to their powder charge weight to keep their muzzle velocity and barrel time constant as the barrel would wear.

Ultimately, I am not after Benchrest-level precision in my loads. Ideally I’d be able to find a load that grouped 0.3-0.4 MOA AND wouldn’t require me to tightly manage or constantly fine-tune my seating depth. Of course, we’d all love to have something that grouped 0.1-0.2 MOA (who doesn’t love a tiny group!), but not if it will only shoot like that for 100 rounds and then it opens up. It seems like longer bullet jumps might be the ticket. At the very least, it has opened my eyes to the fact that a critically important part of load development is seating depth, and not just seating depth but finding a range of seating depths with a similar point of impact. That is at least as important as powder charge weight or primer selection, at least in my opinion.

Thanks,

Cal

Mike,

Years ago I use to load closer to the lands and I have had exceptional results….here and there. While you likely have a higher potential for accuracy up at the lands (This is why bench rest shooters typically do it) it can be a never ending battle to maintain that level of accuracy. What we have found is when you establish the correct bullet jump first, for example around .060″-.090″ with the Berger 105 Hybrids, then finish working up your hand load, it will be much more consistent and have much less change in vertical impacts as the throat erodes. Furthermore, things like charge weight, neck tension and case volume become less critical. That is why companies like Hornady can product factory ammo that has a .5 grain spread in charge weight, have larger variations in case volume than say Lapua brass, yet the factory ammo can still shoot 1/2 MOA groups at 600 yards with an extreme spread in the 40 FPS range. It is because Hornady already understands that bullets like to jump and they give the bullet the jump it wants first, then everything else is less important.

So now we learn Remington had it right all along with those mile long throats, LOL.

Thanks for the very informative read! Can’t wait to see the next few!

It is funny, isn’t it?! What is old is new again!

Thanks for the encouragement, Jon. Glad you appreciated the content.

Thanks,

Cal

Cal or Mark, is there any chance you have correlated velocity/displacement/ seating depth and charted it to see what is revealed. Since those #’s are captured, I just wondered if there would be any surprises showing some relationship to placement and velocity.

Hey, Mike. Great question! That is actually where I went early on to see if simply analyzing the muzzle velocity would be a more pure measurement of the effect this was having, without potential environmental factors being introduced and potentially adding noise to the data. The analysis I did was with a preliminary data set, not the final one shown here, and while I did find some correlation … there was also some differences. If you averaged a group of 15 shots or more together so you had a good sample size, the seemed to be a strong correlation between MV and vertical POI … but if you looked at shot-to-shot, or even had a relatively small sample size of 5 shots or something, the correlation wasn’t as clear. I would share those results, but it actually wasn’t for the same data set … so I’m not sure if it’s relevant. I’d probably have to redo it based on the current data set.

While muzzle velocity is an initial launch condition that will affect the vertical POI at distance, there is more than just MV at play here. As Dan Newberry said relating to the OCW method, changing the seating depth can/will change the group size (i.e. raw mechanical precision of the rifle system). Both initial MV and the raw mechanical precision of the rifle system can affect the vertical POI at distance, so that may account for why the MV was not perfectly correlated with the data collected at distance.

Ultimately, Mark thought group size at distance was what people really cared about, and when you are using a large sample size (like 200 rounds for this 105 Hybrid data), it seems unlikely that environmentals would add significant noise to the data overall. In fact, I guess the statistician said pretty clearly that the patterns we were seeing weren’t from random chance, so that certainly seems to be the case.

Thanks,

Cal

Mike,

We have run tests where the tightest vertical at 600 yards happened to be with shots that had lower extreme spreads in velocity, while we have had some tests that the tightest vertical had the worse extreme spreads in velocity.

So my current position is that at the ranges we tested (600 yards) low extreme spreads in velocity is not nearly as important as some would think. I ran a 6.5 Creedmoor charge weight ladder test AFTER I established that the 147 ELD-M bullets wanted to be at .085″ jump and the first 14 shots out of 15 total were under 1/2 MOA even though there was a 137 FPS extreme spread in the velocity. We see it all the time where we see very large extreme spreads in velocity, while having below 1/2 MOA vertical in impacts.

So your reloading techniques should reflect the goal of getting the lowest extreme spreads as possible, however you really gain your best vertical performance when you give the bullet what it wants, which is a specific jump node. Lastly, we have found that each bullet has a specific jump node that it wants, regardless of the cartridge, barrel length, charge weight or powder type, or rifle system, the bullet has a specific jump node that it wants.

My brain is full now! I’ll give this a try. Thank you guys for sharing your experiences.

Ha! Well, I know there was a lot packed in this one. People tend to have short attention spans on the internet, so I was hesitant to put all this content in a single post … but I thought if any part was left out, you wouldn’t have the full picture. At least for me, if I read this without one of the sections, I’d either have questions or leave skeptical. So I guess that is how you get a 7,000 word blog post! Ha!!! That is about 6,000 words more than the average blog post. But, admittedly … this could be closer to a technical whitepaper than a typical blog post. 😉

I’m glad you’re going to give it a try. I’m with you!

Thanks,

Cal

Thanks for taking us on this roller coaster with you Cal. First it’s another precision metric we need to dial in to improve, then it’s practically insignificant for the use-case at hand… Can’t wait to see where you take us from here.

Ha! Well, I was just trying to bring along new guys who might not have ever heard of bullet jump or freebore … but I admit it was a bit of a setup. Just wanted us all to be educated on what “conventional wisdom” was, before we challenge it head-on. In reality, Benchrest shooters should probably still with their short jumps. It’s just those of us who are firing a ton of rounds over one weekend that might need to balance other priorities, or at least consider a different approach, rather than just copy what guys are doing in other shooting disciplines.

Honestly, this was a blindspot for me. I was just like everyone else, basically either lightly seating into the lands or within 0.020″ of it … never really questioning it. But it was Mark that really opened my eyes to whether there might be a better approach for our application. I talk to a lot of people about precision rifles and have for almost 10 years … but I hadn’t ever heard of someone intentionally jumping bullets this far until Mark started telling me about this research. I’m just glad we finally have been able to get the word out and highlight all the work he’s been doing in the shop on and off over the past 2 years. Good stuff!

Thanks,

Cal

I’m definitely better educated now than I was. I enjoy your style of writing; you make consuming the information smooth, if not easy.

Thanks again for making your expertise available!

I really appreciate that, Matt. That compliment means a lot.

Thanks,

Cal

To be honest, I regret that I didn’t learn mathematics well. Poor math makes it difficult for me to read your article, which is hardcore. but i like it and enjoy, my brain has been thinking actively.

Maybe i should review math

thanks for sharing ))

Smith, I’m a visual person, so just look at the charts and you can see the lowest spread in impacts is associated with jumps that are in the .060″ to .090″ range.

Sorry, bud. I tried to not lose anyone, but I probably don’t even notice how much I use math. It’s the language of science! I know this article was more hardcore/technical than most of my articles. I promise that won’t become the norm, but it was necessary on this one. I will provide an executive summary at the end of the series with what I feel like the take-always are … no math involved! 😉

Thanks,

Cal

This will be very friendly to me (and maybe others like me ).

Please keep the hard-core article and just give a simple conclusion at the end. Even if I can’t fully understand the reasoning process, I will understand the conclusion.

First let me say that the two articles thus far are excellent in attacking the issue of jump – bullet seating depth. However … I’m feeling like something has been “jumped” over. How did Mark establish the load he then used with the same bullets seated to incrementally deeper depths … i.e., longer jumps?

Mark said, “2. Load up 20 identical rounds, except vary the bullet seating depth in 0.005” increments. #1 = 0.000” jump, #2 = 0.005” jump, #3 = 0.010” jump, … , #20 = 0.095” jump.”

Okay … and what load would that be? He obviously didn’t pull it out of thin air. But it has to have been a critical starting point. I’m thinking you could only marginally improve a mediocre load by varying seating depth. So what was the accuracy of the load he started with before experimenting with different jump distances. And more importantly, how was it derived?

Dan Newberry said, “After you have determined the OCW, you may want to try seating the bullets deeper or longer …”

So, am I correct in assuming that using some method like the Audette Ladder Test or OCW established the “LOAD” that is then analyzed? Or perhaps some other method?

Again, I found the articles very educational.

Randolph, great questions. I may make some posts on our website (www.shortactioncustoms.com) so I can do a step by step breakdown on how it all happens. I think it would make more sense to see the complete set up. Regardless I can answer your questions here.

We have found that the charge weight that you run the bullet jump ladder test really doesn’t matter. For example, we did a test with the 6.5 Creedmoor and the 147 ELD-M bullets from Hornady. Here was the format for all 3 bullet jump ladder tests. Same rifle, same testing format.

Test 1

Shooter: Matt Stiner

Charge weight: 41.6 gr H4350

Order to be shot: Standard order 1-20

Lowest Extreme Spread in inches for 5 consecutive shots: .050″-.070″ jump, 1.4″ of vertical at 600 yards.

Test 2

Shooter: Aaron Hipp

Charge weight: 41.0 gr H4350

Order to be shot: Random Order

Lowest Extreme Spread in inches for 5 consecutive shots: .045″-.065″ jump. 1.4″ of vertical at 600 yards.

Test 3

Shooter: Mark Gordon

Charge weight: 42.3 gr H4350

Order to be shot: Reverse order, 20-1

Lowest Extreme Spread in inches for 5 consecutive shots: .055″-.075″ jump. 2.0″ of vertical at 600 yards.

So we can see that we shot 3 different charge weights, 3 different shooters, 3 different orders of the test being shot and virtually the same exact jump nodes for the 147 ELD-M was present. This is just one example of tests that we have performed that show that the charge weight for the bullet jump ladder test doesn’t matter.

When a customer pays us to do a load work up, we will do a lower charge weight and a higher charge weight for the bullet jump ladder test for redundancy sake and because we show all of our load work up data to the customer. It is pretty compelling when we can show two charge weights that demonstrate the same bullet jump nodes.

Randolph, I wanted to break the responses up into different posts to make them easier to ready and follow.

“Dan Newberry said, “After you have determined the OCW, you may want to try seating the bullets deeper or longer …”

From what we have been seeing from all the testing over the last few years I currently disagree with Dan Newberry’s statement…

“After you have determined the OCW, you may want to try seating the bullets deeper or longer …”

I believe the opposite is true and I believe I can present a pretty strong case to back up position. I believe that you should always determine your ideal bullet jump range first, then work up a charge weight. Here is why!

We performed a test to determine if bullet jump affected the results of a charge weight ladder test. Remember, we have demonstrated multiple times where the charge weight (in normal operating ranges) doesn’t appear to affect the bullet jump testing. So we created a test where we did 3 charge weight ladder tests, the only thing that was different was each charge weight ladder test was fired with a different bullet jump for the whole test. So Test 1 had .020″ jump, Test 2 had .050″ jump and Test 3 had .080″ bullet jump.

***We have found in the past that .050″ and .080″ jump were in jump nodes and shot really well for the 147 ELD-M bullets. ***

Test Format

6.5 Creedmoor

147 ELD-M bullets

Lapua 6.5 Creedmoor brass, Small Rifle Primer brass

H4350, thrown to the kernel

Match Brass Prep.

Test 1

Charge Weight Ladder Test

All rounds loaded to .020″ jump

15 consecutive shots increasing in .2 gr increments

40.6 to 43.4 gr.

Velocity E.S. for the whole test: 168

Test 2

Charge Weight Ladder Test

All rounds loaded to .050″ jump

15 consecutive shots increasing in .2 gr increments

40.6 to 43.4 gr.

Velocity E.S. for the whole test: 179

Test 3

Charge Weight Ladder Test

All rounds loaded to .080″ jump

15 consecutive shots increasing in .2 gr increments

40.6 to 43.4 gr.

Velocity E.S. for the whole test: 152

If bullet jump was not more important than charge weight, then all 3 charge weight ladder tests should have fairly similar vertical extreme spreads for the bullet impacts right? After all, we are doing a charge weight ladder test, so amount of bullet jump should not affect the overall vertical of the bullet impacts…….

However, the results contradict that and I will present them below. I’m going to list the extreme spread in bullet impacts in MOA.

Test 1: 40.6-43.4 gr charge weight ladder test with .020″ jump: 1.53 MOA

Test 2: 40.6-43.4 gr charge weight ladder test with .050″ jump: 1.09 MOA

Test 3: 40.6-43.4 gr charge weight ladder test with .080″ jump: 0.83 MOA

Look at test #3. It shot 14 consecutive shots (Shots 1-14) during this charge weight ladder test into a group with only .57 MOA of vertical despite the 143 FPS extreme spread from 40.6 gr to 43.2 gr.

So we can see that the two bullet jumps that have proven to be in the bullets inherent jump node (.050″ and .080″) have considerably less extreme spread in vertical impacts at distance.

Ok, so lets remove the top and bottom outliers to see what happens. I removed the highest and lowest impacts from the test.

Top and bottom impacts removed from the test.

Test 1: 40.6-43.4 gr charge weight ladder test with .020″ jump: 1.37 MOA

Test 2: 40.6-43.4 gr charge weight ladder test with .050″ jump: 0.76 MOA

Test 3: 40.6-43.4 gr charge weight ladder test with .080″ jump: 0.48 MOA

The two ideal jump’s (.050″ and .080″) continue to perform even better while the .020″ jump charge weight ladder test is still close to the original starting point in MOA.

Finally, I removed the top 2 and bottom two shots from each test to just see what it would look like.

Top 2 and bottom 2 impacts removed from the test.

Test 1: 40.6-43.4 gr charge weight ladder test with .020″ jump: 1.08 MOA

Test 2: 40.6-43.4 gr charge weight ladder test with .050″ jump: 0.66 MOA

Test 3: 40.6-43.4 gr charge weight ladder test with .080″ jump: 0.37 MOA

So we can clearly see that when the bullet is seated in a bullet jump node (test 2 with .050″ and test 3 with .080” jump) then your charge weight ladder test will have considerably less vertical in impacts..despite having very similar extreme spreads in velocity.

Mark, I’m on the same page with you regarding all this AFTER you select a charge weight range to study. I guess to make my point – in the extreme – instead of starting with 40.6 gr as indicated in the proceeding last paragraph, why not 20.6? The crux of my question is what established your charge range before doing any seating depth study. The 40.6 wasn’t arbitrary. Something in the range of 40.6-43.4 had to have some proven accuracy … past history perhaps? AND it was the starting point for all three of you shooting. So I’m just asking how you settled on that number range.

I appreciate very much, your input and I’ll look at your website for further explanation.

I’d bet it is past history. Mark builds a lot of rifles, so I’d expect he know more than most people what loads tend to work well in a wide variety of rifles. I’m sure he’ll chime in here in a bit, but just wanted to try to give context.

Thanks,

Cal

Randolph,

I understand your question now. For the tests mentioned above, just from common knowledge and being familiar with the 6.5 Creedmoor, I knew that 40.6 was on the lower charge weight range and that 43.4 was on the higher end. That is it, sure you could do 20.6 gr all the way up to you start to spill powder out the case, but 20.6 gr wouldn’t be a realistic charge weight. So when we formulated any of these test, we tried to use “realistic” charge weights for the bullet jump ladder tests. They were not “hand picked” charge weights that were proven performers.

We have performed this test on lots of cartridges that we have never reloaded for before like the 6.5 PRC, 6.5 SAUM, 7mm STW, and 28 Nosler. So we just chose safe “middle of the road” charges for the bullet jump ladder tests.

Thank you Mark. I knew 20.6 was unrealistic, but was emphasizing the point that there had to be a realistic starting point. And in this case is was based on experience. So, having said, I have had pretty good results with 36.9 gr of Varget in my 6.5X47L, BR-4 primers, Lapua brass, and 140 gr Berger hybrid bullets. Could I then use that load and vary the jump incrementally as you did? Or do you know if a different load might be better for testing jump? I know that you have shot 6.5X47L in the past, so perhaps you have a handle on a starting load.

Thanks again to you and Cal for factually addressing this element of reloading.

Randolph,

Yes, that would be perfectly fine for you to use your current load to do the bullet jump ladder test.

Hi, great job and theme.

Can I ask – what is more important, find a jump or how much load powder.

What to start with?

Good question. I plan to have a more thorough recommendation for that in the last post of the series, but I’ll try to quickly give a few suggestions. Often times, I’m doing load development for a new barrel … but I already have a general idea for what worked well in the last barrel. So if that’s the case, my plan is to start with the same powder charge and test seating depth first, then powder charge. If I’m doing load development for a new bullet and don’t have a clue where the right powder charge might be, I will likely still do powder charge (at least to get it in the ballpark), then seating depth, then might double-check powder charges very close to what I originally found to fine-tune.

That’s at least my thoughts. Mark might chime in if he has a different approach.

Thanks,

Cal

Here are my current thoughts on how to properly work up a load.

There are three topics that need to be ADDRESSED INDEPENDENTLY when working up a precision hand load for bolt action rifles. I will list them in order of importance.

Bullet Jump

Internal Ballistics

External Ballistics

Bullet jump: I believe is most important because the bullet is what is traveling down range and impacting the target. I believe each bullet has an inherent jump node that regardless of the cartridge body, charge weight, or rifle configuration, the bullet will perform best when it is receiving it’s desired bullet jump. As demonstrated above, and many times during our testing, when the bullet is given the jump that it desires, which is inherent to the bullets design, it will offer the least amount of vertical spread. Giving the bullet what it wants is the first step.

Internal Ballistics: Chris Long’s “Theory of Optimal Barrel Time” and Dan Newberry’s “Optimal Charge Weight” are dealing with internal ballistics and have nothing to do with what the bullet is doing once it leaves the rifle. When dealing with Internal Ballistics, each rifle should be treated as a “mechanical system” where every change to this mechanical system will affect the rifles “Optimal Barrel Time”. For example, if you work up an Optimal Charge Weight (OCW) for your rifle with a 26″ barrel, then cut the barrel back to 22″, there is a good chance that your previously worked up OWC load is no longer tuned to the rifle.

We have found the opposite to be true in respect to bullet jump. When cutting back the length of a barrel, it will not change the bullets inherent jump node. All of the data that Cal presented above beautifully shows how regardless of the cartridge body, rifle, shooter, charge weight and other rifle system variables, the bullet jump nodes are extremely consistent and present in all test. That is not true with charge weight nodes, they are specific to the rifle system. So this is why you should determine the bullet’s jump node, then load your OCW test with the appropriate bullet jump.

Furthermore, lets do a quick scenario with QuickLoad and Chris Long’s Optimal Barrel Time Calculator. The Calculator lists a 26″ barrel time node of 1.329 Milliseconds (ms).

6.5 Creedmoor

Hornady Brass

147 ELD-M seated at 2.795″ factory ammo length

41.6 gr H4350

26.0 Barrel

Barrel Time: 1.327

In Quickload, If we change only the COAL to 2.870″ which is roughly a .020″ jump, the barrel time changes to 1.352 which is now no longer in the predicted OBT node predicted by Chris Long’s calculator.

So again, why would you find a OCW which is directly related to Chris Long’s OBT theory, and then change your seating depth which will affect the OBT in Milliseconds, most likely taking you out of the OBT node? It doesn’t make sense to me, especially considering that we have found bullet jump affect OBT tests, where charge weight doesn’t seem to affect Bullet Jump nodes.

Lastly, we have External Ballistics which I believe is only getting the bullets extreme spread numbers as low as possible. Yes, I believe that it is ideal to have the lowest velocity E.S. values as possible, but it is last on my list of importance. We have seen factory ammo produce multiple 5 shot groups at 600 yards with less than 1/2 MOA of vertical, yet the velocity E.S. are in the 30-50 FPS range. You can also reference my previously listed charge weight ladder tests where the first 14 shots seated to .080″ jump only had .57 MOA of vertical despite the 143 FPS extreme spread in velocity. In the scope of this load work up and at ranges to 600 yards and in (where we do most of our testing) velocity doesn’t seem to matter that much. This is because you are 1). Addressing the bullet independently by determining what jump that bullet wants. 2). Tuning the rifle as a “mechanical system” via the charge weight ladder test or OCW test in an effort to achieve Chris Long’s “Optimal Barrel Time”. Lastly, 3). Your loading practices, primer choice, and neck tension should have the goal of lowering your velocity extreme spreads for in an effort to fine tune the load.

Brilliant posting, Mark. Thank you for sharing.

Cal– I would suggest your consider whether the phrase “data driven” is truly reflective of your view. In the end, the data must still be analyzed and a human being assign significance to it or draw conclusions from it. I personally have begun using the term “data-informed” in my Engineering practice.

I no longer say “data-driven” because as we advance our testing and gain more data, it often become far less clear what the data mean. In other words, the data is not self-interpreting and therefore cannot really “drive” a particular conclusion.

Please forgive if this needlessly pedantic; I’m just wanting to reinforce the importance of interpretation and analysis in drawing and supporting conclusions.

Thank you and Blessings.

Thanks, Justin. I appreciate your thoughts, and can see what you’re saying. Data is meaningless, it’s information that is valuable. It takes some informed interpretation and analysis to transform data into information.

I just feel like when you say “data-driven” it speaks so clearly to most people (i.e. non-engineers) about the fact that this isn’t just someone spouting their opinion without some basis of facts and hard numbers underneath it. That’s one of the foundations of Precision Rifle Blog. I don’t want to just share my opinion, even if that is what some people would like. In all my posts, I try to remove my own bias and opinion as much as possible, and focus on some kind of hard data or empirical evidence. Even my “What The Pros Use” series of articles has hard numbers underneath it. It’s not me guessing what most people use, or based on my anecdotal experience walking around matches. I don’t say things like “the majority of guys use __”, but instead say something like “68% of the top 157 shooters said they used __, which is a 42% increase from the previous year.” It’s just a fundamentally different approach than most forums, other blogs, or even magazines use. It’s kind of my niche, because it’s the way I personally think. I don’t care what someone “feels” or “believes” to be true – help me understand the facts that led you to believe that, and then I can decide whether to believe that myself.

I do totally understand the contrast you’re proposing, I just don’t think it speaks as clearly as what “data-driven” does to the general population. You are obviously a sharp guy, so I wanted to try to explain my train of thought that got me to the tag line of “data-driven.”

Thanks,

Cal

Cal Zant

Congratulations on the article and thank you very much for sharing.

Greetings from Brazil.

Thanks, Humberto!

Very interesting discussion! Thanks for sharing and all the hard work that went into the data gathering. One question that comes up in my mind is the underlying assumption behind bullet jump vs throat eroding. The key issue is whether adjusting seating depth from 60 to 80 thou is the same as maintaining seating depth constant as the throat erodes from 60 to 80 thou jump. My suspicion is that there are similarities and that having a longer jump minimizes the bullet start-stop-start cycle and makes the load more forgiving. I’m not 100% sure that it’s a direct equivalent though.

The reason I raise this issue is that I’ve seen barrels where chasing the lands to maintain a consistent bullet jump didn’t help – it actually shot better at the original seating depth despite the throat erosion. I suspect this has something to do with timing of when the bullet exits the muzzle, but there are a ton of variables that go into whether a load shoots well. Perhaps that’s why the longer bullet jump helps, it’s less likely to induce variability in the load as the throat erodes.

Sheldon, that is a very interesting point. You sure might be right. Honestly, there is a lot going on in that short moment between primer ignition and when the bullet exits the muzzle, and while there are some scary-smart engineers who specialize in that topic, I think anyone who claims to know every possible thing about what happens in that window is probably a liar. There are a number of factors and while we like to talk about them as if they are 100% independent, which makes them easier to wrap our head around, but the truth is I’d bet most of the factors are at least loosely interdependent with some potentially unexpected interplay between one factor and the others. I’d suspect that you’d need a massive sample size and a government-sized budget for research in order to separate the signal from the noise on that.

I do agree with your conclusion: “Perhaps that’s why the longer bullet jump helps, it’s less likely to induce variability in the load as the throat erodes.” I think that is what the data is saying here. Up close to the lands seems like it is highly volatile as the lands erode, while a longer bullet jump seems to be less affected as the lands erode, so the POI remains more consistent. Regardless of the underlying phenomenon causing it, that seems to be the pattern in the data.

I really appreciate the intelligent and thoughtful comments and questions. You certainly got me thinking! Like most good research, it leaves you with more questions than answers!

Thanks,

Cal

Thank you for your answer – I greatly appreciate your openness.

Another issue is neck tension – how much effect neck tension is when bullet to bigger jump.

It is important if the neck tension is .002 ”or .004” – what is your experience with this?

Thank you in advance for your time.

Horns, you are opening up a can of worms on the neck tension question. That is a whole different research project all-together! Lot’s of people have strong opinions about neck tension, but there are only two scientific studies I’ve ever read that actually have objective research behind them. The first was from Dr. Harold Vaughn in Rifle Accuracy Facts. It was pretty short, so I’ll just include the full excerpt of what he said on the topic of neck tension: