This is the 4th article in a series on some new research on bullet jumps. Here is a recap of the previous articles in the series:

- Bullet Jump & Seating Depth: Best Practices & Conventional Wisdom

This article provides a comprehensive overview of what most professionally published books and reloading manuals suggest about bullet jump and seating depth when it comes to precision rifles. It also lays a foundation of what we mean by bullet jump, freebore, etc. - How Fast Does A Barrel Erode?

This article focuses on how quickly the lands of a rifle barrel usually erode, especially for mid-sized cartridges that are popular in precision rifle matches. It also covers how many shooters manage seating depth and bullet jump over the life of the barrel. - Bullet Jump: Is Less Always Better?

This article introduced some interesting, new research conducted by Mark Gordon of Short Action Customs on what the most forgiving range of bullet jumps are for the Berger 105 gr. Hybrid bullet over 10 different rifle/load configurations. It also provides an overview of the test methods and how to interpret the results.

In this post, I’ll share more research data Mark has collected related to bullet jumps for two popular bullets used for long range:

- 6.5mm Hornady 147 gr. ELD-M

- 6mm Tubb 115 gr. DTAC RBT

If you missed the previous post, I’d strongly recommend you start there – or this simply won’t make sense. I carefully explained the testing methods and data/charts in the last post and won’t be repeating that info again here.

Fundamentally, this research wasn’t focused on finding the specific bullet jump that provides the absolute best precision (i.e. smallest possible group), but was focused on finding the best precision over a range bullet jumps. We are looking for the window of bullet jumps that would continue to have a similar point of impact over 200+ rounds, without having to adjust the seating depth as the lands of the barrel erode. That means the rifle would be more consistent from the start of the match to the end of it or could shoot a particular kind of match-grade factory ammo really well for a longer period of time.

Here is a visual that illustrates what we’re looking for, which is the big green area that provides both very good precision AND is also very forgiving in terms of bullet jump/seating depth.

This research isn’t saying you can’t get good groups close the lands – many obviously do! But, could we get really good groups AND not have to frequently adjust the seating depth of our bullet? That’s the question this research is exploring.

6.5mm Hornady 147 gr. ELD-M

The last post focused on Berger’s 6mm 105 Hybrid, but Mark has also compiled quite a bit of data on the 6.5mm Hornady 147 gr. ELD Match bullet. Before we dive into the complete results for that bullet, I’d like to start by looking at a unique aspect of the bullet jump tests Mark conducted with the Hornady 147 gr. ELD-M.

3 Loads, 3 Shot Orders: 1 Rifle

A portion of how Mark tested the 147gr ELDM was in three different ways using the same exact rifle. The custom rifle he used for these three tests was a 6.5 Creedmoor in a Defiance Elite action in a McRee chassis with a 26” Bartlein Heavy Palma contour 1:8” twist barrel and a TBAC Ultra-7 suppressor. They ran through the 20-shot bullet jump test, from 0.000″ jump (a.k.a. “kissing the lands”) to a 0.095″ bullet jump in 0.005″ increments, with that one rifle and varied:

- 3 different powder loads (41.0, 41.6, and 42.3 grains of H4350, all in Lapua small primer cases with Federal 205 Match primers)

- 3 different shot orders (shortest jump to longest, completely random, longest jump to shortest)

- 3 different shooters (Matt Stiner, Aaron Hipp, Mark Gordon)

So this was basically side-by-side testing for the same rifle and bullet over a 60-shot sample size and with some variation introduced. Mark obviously shoots a lot, but the other two shooters are accomplished PRS/NRL competitors who regularly place in the top 10 at major matches.

- Matt Stiner fired the 20-shot test with 41.6 gr. of powder in conventional order, starting with 0.000” bullet jump and firing sequentially up to 0.095”.

- Aaron Hipp fired the 20-shot test with 41.0 gr. of powder in a completely random order.

- Mark Gordon fired the 20-shot test with 42.3 gr. of powder in reverse order, starting at 0.095” of jump and ending with 0.000”.

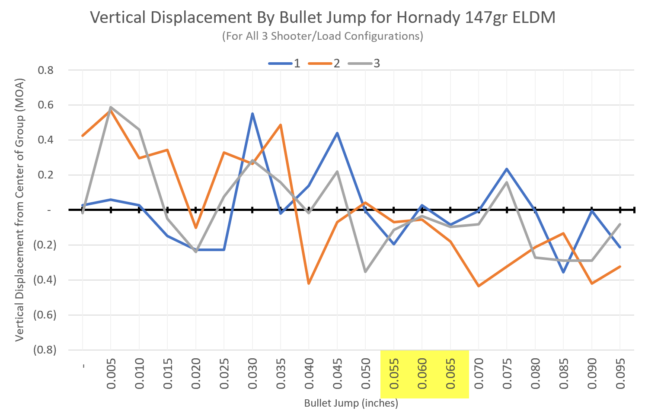

Let’s look at the results for the vertical POI shift each of them recorded on Mark’s electronic target system at 600 yards based on the distance the 147 gr. ELDM was jumping to the lands of the barrel. The chart below shows the combined data for all three tests.

If this is the first time you’re seeing a chart like this, I’d suggest going back to read the previous article to understand what it represents.

Remember, on this chart the flatter the line the better. If a line is steep, that means there was significant vertical Point of Impact (POI) shift over a narrow range of bullet jumps (i.e. the bullet seems to be very sensitive to seating depth near that bullet jump). Mid-size cartridges like this can erode by 0.005” in just 100 rounds (read more on that), so where the lines are steep means you could experience measurable vertical stringing in 100 rounds or less. However, if we can find a section where the lines are flatter, that means the vertical POI didn’t change significantly over that range of bullet jumps. For example, look at the area around 0.055-0.065”. Even with different loads, different order of shots, and different shooters, all 3 tests show very little vertical POI shift over that window of bullet jumps.

You can see that regardless of the shooter, order the shots were fired in, or the specific load used, there appears to be a sweet spot around 0.060” of bullet jump, because all of the lines on the chart appear to flatten out near that area. Also, we can see on the chart above that there doesn’t appear to be anything less than 0.040” of jump that seems to be forgiving, and 0.050-0.070” appears to be best for the rifle that was tested … regardless of shooter or specific load.

And while each of the 3 tests only included 1 shot for each of the bullet jumps, it is interesting to see the commonalities in the patterns. There seems to be very few places on the chart where if one of them is shifting up or down in vertical, the other two aren’t also doing that same thing, except possibly to more or less of a degree. The peaks and valleys may not perfectly line up, but they certainly seem to come close in a few spots!

I noticed a recent forum post on AccurateShooter.com of a discussion related to my previous article and Alex Wheeler, owner of Wheeler Accuracy and a respected gunsmith who has built some of the best shooting 1000 yard Benchrest & F-Class rifles, said something that seems relevant to these three tests. The discussion was around tuning loads and finding the ideal seating depth/bullet jump, and here is what Alex said:

“From my experience powder charge will not drastically effect the correct seating depth. Meaning if you change your powder charge the gun will not go from preferring a .010 jump to a .060 jump. It may move a few thousandths, but I think you can use any powder charge you want to rough in on seating depth.” – Alex Wheeler

It seems like the results here, which are based on 3 different loads, seem to corroborate Alex’s experience. If you would have ran through this test with any of those loads, you would likely land at a similar bullet jump.

There was one more quote from Alex in that forum conversation, which is a timely reminder:

“I talked with Mark about his testing a few months ago. Keep in mind he is looking for the widest tune not necessarily the tiniest group. That’s not to say you may not also find the tiniest group at those jumps. Just know what his goal was with this testing. I do think he did a very good job of achieving it.” – Alex Wheeler

Well said, Alex! By the way, Alex is the only other person I’ve seen present an accurate and repeatable method to measure the distance to the rifle lands on your barrel (watch it here), so I know he is someone who believes in the importance of tuning seating depth and has likely done a lot of precise testing himself.

A Wider Sample Size for the 147 gr. ELDM

Okay, that was just a sample size of 3 tests (60 shots total), so now let’s look at the complete data Mark has compiled so far with the Hornady 6.5 147 gr. ELD-M. We’ll include the 3 tests above, and we’ll add 6 more rifle/load configurations, including rifles chambered in 6.5 Creedmoor, 6.5 PRC, and 6.5×47 Lapua:

- 6.5 Creedmoor: SAC Alpha 11 action in Manners T4A stock with 26” Bartlein Rem. Varmint contour 1:8″ twist barrel, Mark Gordon shooting

- 6.5 Creedmoor: Defiance Elite action in MPA chassis with 26” Bartlein Heavy Palma contour 1:8″ twist barrel, Mark Gordon shooting

- 6.5 Creedmoor: Defiance Elite action in McRee chassis with 26” Bartlein Heavy Palma contour 1:8” twist barrel, Matt Stiner shooting with 41.6 gr. load

- 6.5 Creedmoor: Same rifle as #3, but Aaron Hipp shooting with 41.0 gr. load

- 6.5 Creedmoor: Same rifle as #3, but Mark Gordon shooting with 42.3 gr. load

- 6.5 PRC: Defiance Deviant action in KMW Sentinel stock with 26” Bartlein Heavy Palma contour 1:8” twist barrel, Mark Gordon shooting

- 6.5 PRC: BAT TR action in McMillan A5 stock with Bartlein Rem Varmint +1 contour 1:8″ twist barrel, Mark Gordon shooting with 57.0 gr. load of H1000

- 6.5 PRC: BAT TR action in McMillan A5 stock with Bartlein Rem. Varmint +1 contour 1:8″ twist barrel, Mark Gordon shooting with 58.5 gr. load of H1000

- 6.5×47 Lapua: SAC Alpha 11 action in MPA chassis with 26” Bartlein Heavy Palma contour 1:8” barrel, Mark Gordon shooting

Let’s dive into the vertical POI shift measured for each of those configurations at 600 yards:

That same area around 0.055-0.060” of bullet jump appears to still be a sweet spot for most of these rifles/load configurations. Most all of the various rifle cartridges, loads, and rifle configurations have relatively flat sections near that window of bullet jumps. Compare what is happening there to the spikes and erratic POI shifts that seem to happen closer to the lands on the left side of the chart. There are several rifles that seem to have significant vertical stringing for those jumps that are closer to the lands.

Keep in mind this doesn’t mean the rifles don’t group well at those closer bullet jumps. For example, let’s look at the first red spike, which occurs around 0.015” jump and is related to rifle configuration #8, which is one of the 6.5 PRC rifles. The chart isn’t saying the rifle’s groups measured 0.8 MOA at that jump. It might group phenomenally well at that bullet jump – maybe even under 0.2 MOA. We don’t know, because that isn’t what Mark was trying to test. What we can see in the chart above is the shot with a 0.015” bullet jump hit 0.8 MOA above the absolute center of all 20 shots for rifle #8. Then the very next shot, with an identical load in the same rifle but with a 0.020” bullet jump, hit closer to 0.2 MOA above the center of the group, meaning that shot shifted 0.6 MOA down with only a 0.005” of change in bullet jump. Now, for each configuration there is only one shot for each bullet jump, so we shouldn’t try to draw meaningful conclusions from that small of a sample size. But the chart above contains 180 shots/data points in total, and it appears that some of the erratic shifts in vertical are localized in few distinct areas. There are many spikes and steep lines up and down on the left side of the chart for multiple rifles, but there are relatively few on the right side of the chart for any of the rifles. This tells us that Hornady’s 147 gr. ELDM bullet seems to be more forgiving of changes in bullet jump when you are using 0.050” or more of bullet jump, and that appears to be true over a wide range of rifles tested.

Now let’s analyze the data a different way. The chart below takes the same data as above (180 individual shots in a variety of rifle/load configurations) but helps us visualize it in a way that is closer to the crux of what we’re looking for. To get the data below, we looked across all 9 rifle/load configurations shooting the Hornady 147 gr. ELDM and calculated the vertical extreme spread over a rolling window of 3 sequential bullet jumps. Each column represents a bullet jump window that is 0.010 inches wide, which is approximately what you’d expect the lands of the barrel to erode over 200 rounds for popular precision rifle cartridges. For example, the first column on the left below represents the extreme spread for the vertical POI over 3 incremental bullet jumps: 0.000, 0.005, and 0.010 inches. I calculated the vertical extreme spread over those 3 bullet jumps for each configuration, and then averaged those values across all 9 rifle/load configurations so we could see over-arching trends.

On the chart above, the shorter the column the better. For example, 0.050-0.060” and 0.055-0.065” bullet jump ranges were the two windows that had the most consistent vertical POI. Both of those bullet jump ranges averaged a 0.26 MOA vertical extreme spread at 600 yards over all 9 rifle/load configurations tested! That means they provide outstanding precision, and are very forgiving in terms of bullet jump and the distance to the lands. (It also means there were some very consistent shooters behind those rifles!)

Now let’s widen that window from 3 to 5 sequential bullet jumps, to see if there is still a similar pattern. Each column below equates to a range of bullet jumps that spans 0.020”, which would be about what you could expect to happen over around 400 rounds in popular mid-sized cartridges used in PRS/NRL style matches. How quickly the barrel erodes can vary even for the same cartridge depending on how hot your load is, the quality of the steel in your barrel, how long you allow the barrel to cool between strings, and a dozen other factors, so your mileage may vary. Your rifle lands might actually erode by 0.020” over 200 rounds or it could be 600, but I’m simply trying to give general context for what a 0.020” span of bullet jumps represents.

This chart above seems to tell a similar story compared to the previous one, although the “optimal” area we saw before around 0.045-0.070” is less pronounced after we doubled the size of the window of bullet jumps we were analyzing. Of course, we are still talking an extreme spread of 0.45 MOA over a 0.020” window. Again, that doesn’t mean groups averaged 0.45 MOA in that range, but just that average vertical POI didn’t shift by more than over that entire range for all the rifles/loads tested. It’s possible that groups at any point might be very small (or not), but the areas with lower numbers on these charts simply wouldn’t shift significantly as your lands eroded by 0.020” and bullet jump naturally increased by that amount.

6mm Tubb 115 gr. DTAC RBT

Now, let’s look at a very popular 6mm bullet, David Tubb’s 115 gr. DTAC RBT Closed Nose bullet. This is a bullet that David Tubb designed, and it is manufactured to his specs by Sierra Bullets.

For the 115 DTAC bullet, we have a sample size of 6 different rifles that were tested. One interesting aspect of the setups tested for the 115 DTAC is that all of them used a different action. Here are the details of all six configurations:

- 6mm Creedmoor: Curtis Vector action in MPA chassis with 26” 1:7.5” twist barrel, Matt Stiner shooting

- 6mm Creedmoor: ARC Nuleus action in MPA chassis with 26” Bartlein Heavy Palma contour 1:7.5” twist barrel, Mark Gordon shooting

- 6mm Creedmoor: Defiance Elite action in MPA chassis with Bartlein Heavy Palma contour 1:7” twist barrel, Curt Geary shooting

- 6×47 Lapua: SAC Alpha 11 action in MPA chassis with 26” PROOF Research M40 contour 1:7” twist barrel, Solomon Manansala shooting

- 6 Dasher Norma: Borden Mountaineer action in MPA chassis with Bartlein Rem. Varmint contour 1:8” twist barrel, Mark Gordon shooting

- 6 BRA: BAT TR action in MDT ACC chass with Bartlein Rem. Varmint contour 1:8” twist barrel, Mark Gordon shooting

The chart below shows the combined data, which is for 20 different shots in 0.005” increments from kissing the lands (i.e. 0.000”) up to 0.095” of bullet jump for each of those 6 rifles. So, it represents 120 shots fired with the 115 DTAC.

I’ve been looking at these kinds of charts for a few months now, and it is still tough for me to decipher patterns in this one. I highlighted a couple of ranges that might be slightly flatter than other portions of the chart. The only obvious thing is there seems to be a lot of vertical shift around 0.020-0.040″ for a few of the rifles.

Let’s look at the other types of charts that are based on the same data, and maybe they’ll give us a clearer picture of what windows of bullet jumps seem to be the most forgiving in terms of vertical POI shift.

The chart above makes a couple of ranges of bullet jumps pop out. 0.040-0.050” bullet jumps appear to have minimal vertical shift. It also looks like most bullet jumps beyond 0.070” also provided consistent vertical POI over a wide range of bullet jumps. However, there are a couple of big spikes in the data that show an average shift in vertical of 0.6 MOA or more. The data appears to be saying the 115 DTAC is more sensitive to seating depth, at least across the rifles that were tested here. However, once you get beyond 0.070” of bullet jump, the bullet seems to become very insensitive to seating depth. In other words, the 115 DTAC only appears to be sensitive to seating depth when seating it very close to the lands, but not when you’re jumping it 0.070” or more.

Now let’s look at how consistent the vertical POI is over a window of bullet jumps that is twice as wide:

That “sweet spot” that appeared around 0.040-0.050” bullet jumps in the previous chart seems to have vanished, meaning the sweet spot must not have been 0.020” wide. So while you might not experience vertical stringing in that range of bullet jumps over 0.010” of change in bullet jumps (around 200 rounds of barrel wear with popular mid-sized cartridges), if you pushed beyond that without adjusting your seating depth, the data suggests you’d be more likely to experience a vertical POI shift.

Honestly, you can see that by 0.030-0.050”, it drops off and pretty much gets smaller as you move further and further from the lands. Once you get to a range like 0.060-0.080”, you have an average vertical shift that is less than 0.5 MOA over a 0.020” window of bullet jumps. Remember, that doesn’t mean the rifle ever shoots groups that big, but just that the center POI of your groups wouldn’t likely change by more than that over 300-500 rounds (i.e. it is more forgiving in changes in seating depth or the lands eroding over time).

Wrap-Up & Next Post

While Mark has done preliminary testing on a few other bullets, the Berger 105 Hybrid, Hornady 147 ELDM, and Tubb 115 DTAC represent the ones he has compiled the largest sample sizes for so far. The data Mark collected for these three bullets helps us understand how these “sweet spots” can vary based from one bullet design to another. It also seemed to show that for a particular bullet there seems to be commonalities in terms of what range of jumps are most forgiving even over several different combinations of rifles, cartridges, loads, shot order, and shooters.

While there are slightly different patterns between each of the bullets, it does appear none of the bullets showed to have a forgiving bullet jump under about 0.040”. The most consistent vertical POI over a wide range of bullet jumps usually appeared to be closer to 0.060”. Jumps that have been traditionally seen as absurdly long, like 0.080” or more, actually seem to produce less vertical shift in POI as the barrel wears than when the bullet is seated very close to the lands.

Of course, if you tightly manage your seating depth and adjust it regularly (e.g. every 100-200 rounds), then you can still get extremely precise groups seated close to the lands. That is a really important point. None of this research is trying to say you can’t get tiny groups jumping 0.020” or less, or even seated into the lands. Those minimal jumps could produce smaller groups than if you were jumping 0.060” or more, although that isn’t necessarily a hard and fast rule either. What this research seems to show is that when you are seated close to the lands, your load may not be as forgiving in terms of changes to the bullet jump as your barrel wears and you could experience a vertical shift in your zero if you don’t regularly adjust your seating depth.

The next article will be the final post in this series, and will include some information from other shooters on their experience and how they’ve integrated this into their load development process. Stay tuned!

| Find this interesting? | ||

| Subscribe Be the first to know when the next article is published. Sign-up to get an email about new posts. |

or … |

Share On Facebook |

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

I would love to see 156gr Bergers in 6.5PRC and 109gr Bergers in 6GT

Seth, I would love to have the chance to test them as well, however with my current schedule, I won’t be able to do either of them any time soon. All of the shooting that we have performed has been funded by Short Action Customs. So it is not like I’m getting paid to do these tests or getting sponsored help with all the loading and components. Maybe this summer I can free up some more time to keep testing.

I am really curious to hear what you guys found out about the 110smk. It is the most notoriously finicky bullet in this game. I have shot close to 1000 of them in multiple cartridges and many barrels with 7.5twist, 7.3”, and 7”twist from .010” jammed to .100” jump. I have many friends that have done the same. I have thought about getting a 6.75” twist just to succeed, maybe I need to jump even further out. We all report the same info of the flyer in an otherwise solid group. I partially blame it on a mental block. If I were shooting hybrids I would blame myself or a downdraft at distance. However with the 110smk I tend to blame the bullet.

Hey, Donald. We originally planned to include data on the 6mm Sierra 110 Match King bullet, but this week decided to pull it from the article because we only have a small sample size of data for it of 4 tests. But, our original thought was to include it to show an example of a bullet that seems to have very narrow tuning windows, which sounds eerily similar to your experience. So I’ll go ahead and share the data we have, since I already created the visuals and it seems like it’d be helpful for you personally. Just keep in mind it’s a small sample size compared to the data we’ve shared on the other bullets.

I believe that represents all the data that Mark has confirmed for the Sierra 110 gr. SMK. I know there was a lot of shooters who got excited about it when it was first released, but it seems to have quickly fallen out of favor for many shooters and hasn’t gained a wide following. I have to wonder if this might be at least part of why that is. Again, with a limited set of data on it, I want to be careful to not draw too strong of conclusions.

I’m sure Mark might have more thoughts on this that he wants to share too.

Thanks,

Cal

I really appreciate both you and Mark sharing this information. It is unfortunate the 110 is so finicky, because the BC is there. My load of 31.5g Varget/450/dasher has been phenomenally consistently in terms of long string ES and SD for every barrel. Which has not made it any easier to give up on it, haha, oh well it’s perfect for fire forming. Honestly it is probably accurate enough for the game.

The rest of the data you guys compiled will prove to be invaluable to many shooters. I guarantee you will see a new trend of PRS/NRL shooters that start jumping hybrids in the .065” range.

Thanks, Donald. I am with you. It’s tough to give up on a load when you seem really consistent velocities, but it just isn’t grouping like you want. Like Mark said, there are more than a couple of shooters that seem to have a similar story with the 110 SMK. I’m not sure if it’s the shape of the ogive or what. I’m sure Bryan Litz, Dave Emary, or some the ballisticians at Sierra have an idea what it probably is about the design, but the rest of us just have to learn the hard way!

I do think this could be the start of a new trend. At the very least, I hope it makes guys question what might be best for their application and hopefully try it out for themselves to see what works.

Thanks,

Cal

Thanks,

Cal

Donald,

I personally have and I know lots of shooters who have had short “Honeymoon” phases with the 110’s where they are unstoppable one moment, then cannot produce 1 MOA groups. The 110’s seem to have only a .005” window which is around .040” jump. It is a super picky bullet with an extremely small jump window.

Were bullets sorted by ogive?

Great article by Mark, You and the contributing shooters. Listened to the Modern Day Sniper Podcast with guest Scott Satterlee just the other day about this subject. It got me to thinking. If you already have your throat cut should you jump a bullet .060″ by seating the bullet deeper? Could it cause a pressure spike? or plan this into your next rifle build with having the freebore cut back more?

Great series of articles, guys. I’ve had a few ‘surprises’ over the years that are similar in nature to the “mo jump mo betta” philosophy here, but I’ve never tried taking it anywhere near as far as described in this material. Guess I’ll put that on the ‘to-do’ list to try out soon.

Question for Mark (or whomever): have you found the same sort of results on the bigger magnum cartridges? Given the large amounts of powder involved, and the expense of the projectiles, etc. it would be *very* nice to find an approach that reduces the need to ‘chase’ the seating depth on those beasties. Also… does it carry over to solid projectiles?

Thanks, Monte! Honestly, I’d never really tested seating depth much before this. I would seat to what I thought was barely touching the lands or just BARELY off the lands, and do load development for powder charge and go. So this was eye-opening for me too.

I’ll chime in with that I’ve heard about magnums, and I’m sure Mark will add his thoughts too. Scott Satterlee believes magnums like to jump even more than what we’re showing here. In the next post, I plan to share some details a friend from Accuracy International told me about after he read my last post. I don’t have all the details ready to share yet, but the summary is after extensive testing on their new Advanced Sniper Rifle in magnum cartridges they also found longer jumps gave better performance. In fact, they specifically said, “The results even surprised me with an increase in accuracy of 19% with the 300 grain bullets jumping about .100″.” That was in the 338 Lapua. Like I said, I’ll mention more about that in the next post, so stay tuned for that.

I’m not sure how much of this translates to solids. I’d suspect the testing method could be similar, but I wouldn’t be surprised if the results were different for solids. It seems like they are a completely different animal all together. However, after my post on the “conventional wisdom” when it comes to bullet jumps (meaning jump 0.020″ or less), several people left comments saying that solids typically prefer to jump further. There are several comments in that post talking about it, and you can read those here.

Mark, would you mind sharing what you’ve found on bigger magnums?

Thanks,

Cal

Great work Cal. Great work.

These results are so close to our test results (albeit for copper bullets) that I have a very high level of confidence in your findings. (When you are the only one talking about such things, it’s hard not to feel like John the Baptist preaching in the wilderness – the assumption is always proprietary interest)

Regarding the larger calibres, (and by larger – I mean 375 CT and up) we use a jump of 0.065″ for best results (with our bullets), as opposed to the 0.050″ we recommend for the smaller calibres and cartridges.

You have no idea how much encouragement we take from your latest “findings”. Data beats factoids every day!

Love this stuff

Thank you!

Steve Hurt

That’s great, Steve! Thanks for chiming in and sharing your findings as well. (For those reading, Steve is from OutrrEdgeProjectiles.com.au)

Thanks,

Cal

Wow! My mind is in a pretzel right now from you and the Modern Day Sniper Podcast with Scott’s interview (I need to re-listen after reading your articles) . I have a new barrel being spun up right now, so in 6 weeks, I’m going to be at square 1 trying to find a load. What do you guys recommend I try and start with jump at? Thanks for all that you do

Ha! That’s awesome, Rob. I actually plan to try to summarize how we’d recommend approaching load development in light of all this data in the very next post, so you couldn’t lead into it any better for me! That should be up in less than a week, so you should have it in plenty of time. A lot of it will align with Scott Satterlee, because I’ve had a few conversations with him about all this. So I doubt there will be many surprises for you if you’ve already listened to a podcast about his method.

I actually didn’t even know they’d published a podcast on Scott’s approach to load development. I plan to go listen to that right now. For the others that might like to do that, here is a link:

Modern Day Sniper Podcast: Scott Satterlee and Hand Loading (Episode 14, Published April 1, 2020)

Stay tuned for the next post, Rob!

Thanks,

Cal

Rob,

I didn’t catch what rifle, cartridge or bullet you’re planning on shooting. We have had an extremely high success rate “spoon feeding” others the correct bullet jump and having them load extremely accurate. But with out knowing what you’re doing, it is hard to help with a recommendation.

What you’re going to want to do is start with bullet jump, then move over to charge weight.

Mark, Thanks for commenting back! I’m going to be running a 6.5×47 Remage, 24 inch barrel, 1-8 twist, have a bunch of 140 Hybrids or 130 ELDMs, and H4350 and 4451. I’m thinking I’m going to start with the Hybrids and H4350, but if you have other recommendations, I’m all ears as you’re an expert.

Thank you for all you do for the shooting community

Cal,

I think this is one of the best series you have posted, thank you.

I am going to put this info to work on my 7RM.

Best regards,

Phil

Thanks, Phil! I was sure excited about it. It’s why I went dark for a couple of months there. This was a lot to work through, and I wanted to be really careful in how I presented it so that guys could really understand what it’s saying. I’d be embarrassed if anyone knew how much time I spent on this! Mark put a lot of time into it over literally years. But, we’ve both been pleasantly surprised by how well this seems to have been received by the shooting community. This was WAAAAAYYYY off the established path and counter to what many thought of as “best practices” or “conventional wisdom” … so we actually thought there would be a lot of guys pushing back on this or simply dismissing it. Scott Satterlee even told me, “I didn’t want to tell anyone what I was doing, because I didn’t want them to look at me like, ‘What’s wrong with you!'” If you knew Scott, that is a really rare thing for him. I think most of the time Scott couldn’t care less what people think, but this seemed almost like blasphemy in the shooting community. But, like I said … we’ve been pleasantly surprised by the reaction from shooters. At the very least, we were just hoping people would go try it for themselves. Obviously we aren’t trying to sell anything here. In fact, I literally don’t sell anything … all my content is free! Just trying to help out other shooters. So I’m encouraged to hear that is exactly what you’re going to go do: Go give it a shot!

Thanks,

Cal

Mark at SAC actually made the rifle that I am shooting now. However it’s a .308 and not a “competition” caliber. Mark mentioned shooting the 178ELDX for hunting with a 0.04-0.06 jump however I decided to shoot the 165 GameKings. I have shot 168 Hornady MATCH out to 1000 yards but seemed to find out that they don’t do too well past 750. (All loads seated 0.020” off the lands) After doing more reading I saw that I needed to go heavier or to the 155 scenars. With my 1/10 twist I decided to go to the 175 SMK. I haven’t been able to do any load development with the 175SMK yet because I just got the bullets and I’m waiting on more powder. Do y’all have any recommendations on where to start or how I can test this?

Galen,

We have only did a few tests with the 30 cal. Sierra 175 SMK but have found that the 175 SMK’s like the classis .020″-.030″ jump. So I would give that a shot.

By the way, the 175’s touching the lands with the “standard” .070″ freebore reamer is around 2.830″. Putting factory ammo loaded to 2.800″ right at .030″ of jump. I think that is why most rifles love 308 factory ammo with 175 SMK’s.

Have you done any testing on the .224 Valkyrie ? Any bullet weight ?

Dave,

We have not had a chance to test much of the .224 cal bullets.

Cal, first I would like to thank you for all the work you put into these posts. I always find them beautifully written and extremely worthwhile!

In installment 3 of your bullet jump series, you give velocity data for the first set presented (“test #5 data”) from Mark Gordon’s research. There does not seem to be any correlation between velocity and the Y-coordinate of the shots on target.

So, what accounts for the vertical spread at 600 yards?

In other words, is there a (lazy?) way to acquire data to determine a forgiving bullet jump at 100 yards, or is it necessary to find a method to identify individual shots on target at 600 yards?

Thanks, David. I appreciate the encouragement and kind words!

It’s true that you can’t get everything you need to know about a load by just looking at muzzle velocities. There is not a 1-to-1 correlation with where the bullet hit and muzzle velocity. There is some correlation, but not perfect alignment. While that is sure convenient to only look at muzzle velocity when doing load development, it probably shouldn’t be the only variable you make decisions on. There is an element of raw mechanical precision (i.e. grouping) that involves harmonics, barrel time, and a bunch of things I admit we don’t know a lot about in definitive terms. Now, I’m not talking about group convergence or what some people call positive compensation (i.e. groups being larger at close range and smaller at long range). I think Bryan Litz did a great job exploring that topic in Modern Advancements Vol II. I’m just saying that sometimes you can have extremely consistent velocities and that doesn’t necessarily mean you have small groups. Likewise, you can sometimes have tiny groups, but your velocity extreme spread is ridiculously big. I’ve had experience with exactly that recently. The fact is, muzzle velocities and group size are different variables. Maybe not 100% independent (likely somewhat interdependent), but they are definitely not the same. One can change to a greater or lesser extent relative to the other.

However, I’ve spent a lot of time trying to think through how you can try to get the benefit of this kind of testing at shorter ranges, and I’ve talked to several people about it recently too. I hope to provide some tips in the next article, but there is still a little bit of experimentation I hope to do myself this week at the range before I start recommending something to other people. But, I have some ideas … I just haven’t figured out if they are good ideas or bad ones at this point! 😉 Ideally, you’d be able to test all this at distance, but I know that might be impossible for some and really inconvenient for most, so I’m trying to find a way that would give you the most benefit and resolution possible at shorter ranges. I will say I’ve already tried this out a couple times, but I think I have a few refinements to my methods that will help, and I hope to put those to the test this week.

I plan to speak to this directly in the next post, which should come out within the next week or so. I just want to try out a few ideas myself before I start suggesting things.

Thanks,

Cal

Thanks for your reply! I’ll be looking forward to the next installment.

And, for what it’s worth, I am shooting a 6.5 mm Creedmoor using 140 gr Nosler RDFs with a jump of 0.080″.

Very interesting as usual Cal! I looked at my notes on the DTAC I had commented on the first write up on this that I look for round groups well testing and do 0.030 steps well testing with the dtac 0.060, 0.090, 0.120 had similar results. Thanks again for your time and effort! One thing I should say is this testing was done sub 200 rounds down the pipe 1200 and change later I have not changed my load still going strong (I’m using a 6 slr) I really like you sharing the different methods of finding the lands. That is something I have struggled with over the years as I was looking for the lands to make a mark. 6-8 years ago I spent a couple thousand rounds developing my load testing process using a 223 well running “relatively” 😇 stiff loads I discovered that I have a pressure spike as soon as the bullet started having any marks on them so I deducted that to me the lands start as soon as there is a mark.

I’ve found it interesting or affirming that different things that are coming out with load development I’ve been doing for a number of years and have felt that I’m just not a good enough shooter to see these differences that people talk about over a couple thousandths or a tenth of a grain!!

Has anyone noticed a difference in gun torquing/ twist with different seating depth? Maybe I’m nuts but with heavy bullets I feel the gun torque more with less jump particularly when jamming the bullet.

Thanks, John. This has been really interesting for me to learn about and analyze. I was excited to publish this series, and I know Mark has been as well. It is good to hear that the 115 DTAC data we published here seems to match your own test results. That is a sweet bullet. I ran it in my competition rifle for two years. I recently switched to the 110 A-Tip, but only because I like to tinker and I wanted to play around with those bullets. The 115 DTAC is still a killer bullet, and I think one of the best choices for a 6mm. It is a wind cheater!!!

And it’s funny you say that about measuring the distance to the lands. I had the same experience. I was just using a technique to look for marks on the bullet, but then Mark told me about his method and I’ve been doing that for the past couple of months. I have been SHOCKED by how far off the old method was. It turns out the bullet is in contact with the lands for a considerable distance before it makes marks on the bullets. I have measured the distance to the lands with Mark’s very precise and repeatable method, and compared it to my previous measurements that I’d used for my load development, and it turns out most of my loads were seated into the lands a considerable distance … even those I thought I was off of them. In some cases it was so big that I’m too embarrassed to say how much it was. But, I know now! In fact, to get off the lands I had to seat the bullet in so far that now I’m back within magazine capacity with one of my loads, where I just had to single feed before. So it’s been an eye-opener for me. It does make sense that marks wouldn’t instantly appear when you first make contact, but I just hadn’t ever put much thought into it before this.

I do think there will be an endless debate forever about what matters and what doesn’t when it comes to load development. We’ll all fixate on something (me included) as really important, and then we’ll figure out it wasn’t as important as this other aspect, and then we’ll all focus on a different part. We are a funny crowd, and I’m definitely including me in that. I often describe myself as “Strong opinions, loosely held.” If I believe something is true, I usually hold that conviction very strongly … but I’m open and willing to be convinced otherwise. I try to not be overly dogmatic or have a fixed mindset about things that can’t adapt to new information. So some of this is new information is coming out. More people are involved in the sport of precision rifle shooting than any other time in history, so there is a lot of passionate people and new research being done that is furthering our understanding. There are also new products coming out, and people trying to market them and convince all of us we need their new tools … so that is mixed in there. In this case, with bullet jump … we have nothing to sell, but sometimes people are touting new research because it leads you to “need” their product. That is where we all need to be careful.

I also think our equipment is now capable of more than it was in the past. Our rifles and the tooling used to build them are 10 times better than 20 years ago! As shooters, we also have access to a lot of training videos and materials that has advanced the entire field of shooters, which wasn’t available to most people just 10 years ago. If you live in Michigan and don’t know one single person who knows anything about long range shooting … if you have an internet connection, you can get into this sport and actually become pretty proficient at it, even in isolation. Because of the huge leap in our equipment and ability, aspects that used to be “in the noise” and “not important” may now become measurable. If you were using an old rifle and you could only group 1.5 MOA and your muzzle velocity had an extreme spread of 50 fps, then using a mandrel to more consistently expand your necks probably isn’t going to produce a measurable difference. But today, you and your rifle might be capable of under 0.5 MOA and if you are careful in other steps of your loading process, then it might make a measurable difference to use a mandrel to expand your necks. So it was true that it “wasn’t important” in the past, but that may not be true anymore. It wasn’t necessarily that we were wrong before, it was just that things have changed since that time … as they always are!

But, of course sometimes it was just that we were wrong when we thought it was super-important, or at the very least it wasn’t as important as we once thought it was. I have a friend in the industry who is deep into research and development and his company makes some of the most precise rifles in the world, and he has this quote in his email signature:

That will make you stop and think about it for a second! That quote makes me smile almost every time I see it, because it is just so true! My friend who has that in his signature could be privy to more cutting-edge research than just about anyone in the industry, but I see that quote as him having enough experience to know that we can often get too swept up into a specific thing being critically important. I’ve also heard it said, “If everything is important, nothing is.” If everything has the same level of importance, it is kind of like you saying you don’t know the list of priorities or you can’t provide any direction for what MUST be done. Another good one is, “If everything is life or death, we’ll all be dead a lot.” They all hit around the same idea of how we as humans can over-emphasize the importance of things.

Sorry for the book-long response! I just resonate with a lot of your remarks, and it sparked a few thoughts that seemed relevant to this discussion.

I don’t have any experience with torquing/twist that you were asking about, but maybe someone else reading this will chime in with their experience.

Thanks,

Cal

Cal and Mark

Thank you for sharing your test results.Do you have any data about 6.5mm 140gr Berger hybrid?

Percy,

I do not have any tests that we have run yet on the Berger 140 Hybrids.

I think thus funny that you guys are just discovering this. Benchrest shooter have been doing this for decades.

Maybe we are slow learners … but I also haven’t ever seen any professionally published materials suggesting this. Tony Boyer and Mike Ratigan are two of the best Benchrest shooters in the world, and they both said they jam bullets into the lands in their books. I do know it’s easy after research like this is published to say, “Well, I knew that all along. That’s what I’ve been doing the whole time!” But, the fact is, this hasn’t been widely known or practiced in the shooting community, in any discipline that we’re aware of. If it has been, please show me where any professionally published materials suggested this. Maybe we’re missing something, but this seems like news to most shooters.

Thanks,

Cal

We used to have Precision shooting magazine and shooters news. Long gone. I use to read them. I’m only 51. I’m not bitching just laughing. Dick Wright would be too..

Hey Cal, this is some interesting data. It does seem to line up with my own observations in testing seating depths with various bullets, but I always assumed that it was just an oddity of the firearm I was using at the time.

That said, do you have or Mark have a working hypothesis as to why this would be happening? It seems somewhat difficult to reconcile this behavior with relatively recent findings regarding primer/powder/projectile interactions. Specifically, that the primer ignition alone is typically sufficient to cause debulleting and initial engraving. Ritter and Beyer of the ARL have some interesting papers regarding this. (https://apps.dtic.mil/dtic/tr/fulltext/u2/a622138.pdf)

Thanks, David. I appreciate the feedback, and especially appreciate you sharing that research study with me. Believe it or not, I was actually reading something just last night that made me start thinking about how much neck tension it might take to prevent the bullet from moving from the primer flash. Litz suggested in Modern Advancements Vol II that would be an interesting thing to do future research on, and it got me thinking about it again. That study you shared appears to be a government research project on “Primer Output and Initial Projectile Motion” … so that is right up my alley! Very timely! I’m DEFINITELY going to read that article. It shows how much of a nerd I am that I get excited to read things like that, but I do!

I will say that we’ve discussed a few theories for why this may be happening, and even had conversations with some guys who are deep behind the curtain in defense research about what they thought. While there are some interesting theories, I don’t know that anyone feels confident that they know for sure why this occurs. That’s why I wasn’t planning to share those theories in the posts, because I try to focus on the data and not on opinions or theories … but when someone asks a direct question like you did, I always try my best to answer it … so here goes!

Maybe the only thing that seems like it might be fairly agreed upon is “seating the bullet in the case so that it contacts the rifling in the throat increases the peak chamber pressure, which is not desirable.” (From Dr. Vaughn in Rifle Accuracy Facts). Dr. Vaughn also said, “The pressure change caused by changing bullet seating depth in the case can also be deduced from Reference I for 0.308 caliber bullets. The peak chamber pressure will drop about 1000 psi for every 30 mils of additional distance (free run) between the bullet and contact with the lands in the throat. In other words, if you seat the bullet so that it has about 60 mils of free run before contacting the Lands, the peak chamber pressure will be reduced by about 2000 psi.” So it’s not just that when you are seated into the lands that peak chamber pressure is increased, but the further you get from the lands the more you reduce peak chamber pressure. But, Dr. Vaughn’s next sentence there is, “This means that the chamber pressure is not very sensitive to seating depth.” So, I guess in the grand scheme of things a 2000 psi reduction in peak pressure isn’t much.

Beyond that, it seems like we get into people’s theories … which in some cases are wild guesses and some cases educated guesses. I’ve heard it suggested that given the bullet more “free run”, as Vaughn called it, may help it make a smoother transition into the bore. I think some of that theory hinges about the idea you shared about is the primer alone enough to dislodge the bullet from the case and get it moving forward. Someone suggested that it is enough to dislodge the bullet from the case (and again, I can’t wait to read that research paper to learn more), but it isn’t enough force to get the bullet moving down the bore. So the bullet starts it’s forward motion, but when it is lodged into the rifling it stops momentarily as chamber pressure builds. Eventually, pressures reach the point where the pressure behind the bullet is enough to get it moving down the barrel. Dr. Vaughn talks about something pretty related to this, and sums it up with, “My guess is that the force is proportional to the caliber and the pressure required for engraving in the throat remains more or less constant at about 10,000 psi. If you compare bullet motion in Figure 2-23 with the pressure in Figure 2-21 you will see that the bullet doesn’t move until a chamber pressure of about 10,000 psi is reached. Once the bullet has passed through the throat the friction force required to move the bullet in the bore is about 80% (480 pounds) of the engraving force, although this friction force is likely reduced as the bullet moves faster.” Giving the bullet more free run might allow it to build enough momentum that it doesn’t have a herky-jerky/start-stop entrance into the rifling. I say all that very hesitantly, because I don’t feel like I know enough to say any of that with confidence. But, the guy I heard say it was a very sharp guy and I just want to pass along the theory I had heard.

Another theory I heard is that more “free run” allows gases to escape around the bullet, and as that gas starts to flow from the chamber down the bore it “guides” the bullet with hydraulic pressure to the centerline of the bore. I’m not sure about that one either. I think seating the bullet into the lands may actually help ensure the bullet is centered with the bore, and Dr. Vaughn, Tony Boyer, and Nathan Foster all repeated that sentiment in their books. But, it’s just another theory related to this I’ve heard in passing in one of the many conversations I’ve been in with people about this.

Ultimately, I don’t know! Again, I’m hesitant to say any of this too strongly, because I feel like I haven’t read or heard anything where someone had a lot of confidence or data behind what they were saying. I do think a critical part of whether these theories hold any water is whether the primer flash dislodges the bullet, which is why I was thinking about it last night … and why I’m so excited to read the research you shared. At the very least, I wanted to share a few of the theories that I could recall hearing in conversations about this with some guys in the industry.

Mark may have heard other theories, because he has probably had more than twice as many conversations about this over the past 2-3 years than I have. Mark, please share any here if I’ve missed one or you have heard variations of what I’ve tried to share here.

David, thanks again for sharing that!

Cal

Thanks for the reply Cal!

The Vaughn book is excellent, easily the best book on rifle accuracy I’ve ever read. Since reading your post I have been wondering about that “free-run” as well. I think I could potentially buy the theory that a longer jump gives more time for the pressure to build and limit the start-stop-start behavior.

The blow-by theory isn’t one I had heard before, it seems less likely to me than the first. Especially if the bullet has already begun to engrave prior to pressure building. Still worth considering though.

As far as the debulleting goes, the current theory (as discussed in that paper) is that the primer flash essentially slams the powder bed into the back of the bullet, dislodging it from the case. Some further research on that ties directly into your point about seating into the lands to ensure the bullet is centered.

Minnicino and Ritter have a follow-up paper (Simulation of Asymmetric Shot Start in Small Caliber Ammunition) that investigates the effects of the fact that the propellant bed is not uniform. The general takeaway from the paper is that, due to ullage at the top of the case, the bullet is actually pushed from the case with a slightly nose-down angle. Seating into the lands would presumably help mitigate that.

Primer effects aside, just looking at the problem from a geometry angle (no pun intended), seating closer to the lands limits the amount of runout the bullet can have.

All things considered, it’s a tricky problem! Curious to see what you guys find out down the road.

P.S. If you’re interested in that second paper and can’t find it, email me and I’ll get a copy to you.

Very interesting! Thanks, David. I will try to track it down, but will reach out if I can’t dig it up. I have the other one printed out and hope to start on it tonight!

Thanks,

Cal

David,

While I am always driven by the question “why”, with the topic of bullet jump, I’m not sure we will ever get to the bottom of what EXACTLY is happening inside the cartridge body and chamber when ignition happens. I feel like all we can do is theorize about things. Surprisingly, I am not that concerned with “why” this is happening, I just want to see what happens because of it.

So with that being said, here is my current operating theory as to what all of this data is telling us… I think the data demonstrates that the bullets ability to hold tighter vertical dispersion at distance is an effect of bullet jump which is specific to the bullets design rather than an effect the rifle system or Internal Ballistics. The bullet needs to be addressed separately and as its own entity and not just an afterthought when wrapping up Internal Ballistics tuning via Chris Long’s theory of Optimal barrel Time” and OCW testing.

The reason why I believe that is because we have a large sample size with lots of variables in different rifle systems, charge weights, powder burn rates, barrel configurations, cartridge bodies, and primers, all of which are considered Internal Ballistic. But regardless of all of those variables, the tests show a strong statistical significance in the highlighted bullet jump nodes.

So I believe that the bullet needs to be addressed first and we need to determine the proper bullet jump. Next we need to find a charge weight that achieves “Optimal Barrel Time” (Internal Ballistics), lastly, we should be tuning this hand loaded ammunition to achieve the lowest extreme spreads in velocity (External Ballistics).

Thanks for the reply Gordon!

I’ve always been driven by the ‘why’ myself, but I do tend to agree with you. The sheer complexity of the internal ballistics process makes it unlikely we’ll ever have a complete understanding. After all, as mathematician Horace Lamb said, “I am an old man now, and when I die and go to heaven there are two matters on which I hope for enlightenment. One is quantum electrodynamics, and the other is the turbulent motion of fluids. And about the former I am rather optimistic.”

I also agree with your assessment of the data, it does appear that the jump sensitivity is purely a function of bullet itself. I guess the question now concerns which aspect of the bullet is significant. You mentioned in a different reply that you/SAC are funding the whole thing, so I don’t know what your budget for the project allows. That said, it would be extremely interesting to test a variety of bullet shapes for a single given weight and compare to testing a variety of bullet weights for the exact external shape. My gut instinct would be that the shape is more significant than the total mass/location of center-of-mass.

On a bit of separate note, I think the “Optimal Barrel Time” theory is given unwarranted credibility. To start with, the math/model he uses is based on the assumption that the speed of a stress wave in a barrel matches the theoretical value for the speed of sound in steel (~5790 m/s). This is only true in the ideal case. If you were to measure the speed of sound in an actual barrel you will get a value closer to 5100 m/s (~12% difference). This is due to shear waves dissipating a portion of the energy of the initial impulse. Additionally, the nice flat areas in his plot of the muzzle diameter vs time simply don’t exist in data extracted from a more sophisticated model (https://imgur.com/4A9v3Fp). I won’t deny that people have used his approach to good effect, but I don’t think it’s nearly as solid of a theory as it’s often presented to be.

All that said, I’m curious to see where this project takes you!

Well hell….I picked a bad day to quit sniffing glue! My brain is fried, I can only imagine what shape yours has been in sifting through all the data. Actually very encouraging news and much appreciated. Question: I know that with the 147gr ELDM (the bullet I have been doing all of my load development with on my Creedmoore) anything short of 70 thou off the lands will not fit into a magazine. I assume you guys single hand feeding those rounds?

Kenny,

With the “standard” .199″ freebore 6.5 Creedmoor reamer, the 147 ELD-M bullets should be touching the lands around 2.890″ +/-. So that will work perfectly fine in Accuracy International AW magazines, Accurate Mag magazines with out the front plate, American Rifle Company ARC 10 round magazines and others. While we did single load every shot, they would have fit perfectly into any of those magazines listed above at their longest length of jumping .000″.

I would try jumping .055″ and pick your previously used charge weight and see how it does.

Hi Cal and Mark, many thanks for the really insightful testing that’s going on. Really impressed with the approach and volume of interesting data.

Two questions;

1. For rifles with same calibre, were they all chambered using the same reamer and length of freebore? Just wondering if similarities in data points may be related to the same reamers (freebore, leade angle etc) being used?

2. Related to the above, what sort of freebore is being used and does this affect the data? Obviously you’re testing jump to the lands, but if the throat is cut long, then a bullet is seated not as deep in the case/neck shoulder junction even when jumping a long way. Conversely, if the freebore is short, then even touching the lands the bullet will be deep in the neck, and if jumping to the lands with a short freebore, the bullet is going to be very deep in the powder column.

Freebore definitely affects pressure generation. Will this also affect the data you’re collecting?

I know it’s extra variables, but it might be interesting to run multiple tests of the same calibre (eg 6.5×47…whatever) but using different reamers…or at least with different freebore. That should help determine if it’s not necessarily being close to the lands or not, but if the bullet needs actually to be seated deeper in the case or further out of the neck.

Dunno, you may have already considered this. Thoughts?

Konrad,

Thank you for your comments and thoughts. Early on in the testing I did a lot of shooting with the 115 DTACs with my personal 6×47 Lapua rifle. My standard reamer back then had .100″ freebore. When I first started testing the 115’s I was having to shove the 115’s so deep the in case that the bullets caliber/boat tail junction was right at the cartridge’s body/shoulder junction. So it was seated way deep and if I would have taken a picture and posted it on social media, there would be “wailing and gnashing of teeth”..lol.

So I ran the test and had “typical” results with the 115’s liking the .065″-.090″ range. Then later on, I throated it out to around .210″ freebore and ran the same exact barrel with the same test, at a later date and I got the same results. The 115’s liked to jump around .065″ to .090″. We did the same thing with the 6mm Creedmoor. We had a .150″ freebore, then I throated it out to a little over .200″ freebore.

Scott Satterlee has had similar results with his 6mm Creedmoor with the 115 Nosler RDF bullets.

Lastly, Rifle #4 listed above was a 6×47 Lapua that we chambered for a team shooter who shoots the 105 Hybrids and we used our .100″ freebore reamer. So his rifle with a Proof Research M40 barrel showed nearly identical results as well.

So what one of my biggest take away’s from all of this shooting and testing is that the jump is inherent to the bullets design and the bullet desires that jump no matter the barrel length, barrel rifling profile, cartridge body, powder charge or powder type. It is inherent to the bullet.

Mark – that’s really very interesting. I think that somewhat takes pressure off getting the ‘right’ reamer or ‘right’ amount of freebore. I think so many people really over think or worry too much about their freebore when having a custom barrel spun up – I know I do. Your findings will help me to chill out a bit. I can focus more on the bullet and locating the optimum window of jump, rather that obsess over the optimum freebore to seat a particular bullet with its boat tail at the perceived ‘optimum’ depth in the case.

Many thanks Mark, Cal and all.

So Mark, given that it appears to be inherent to the bullet, have you done any work with 7mm bullets? And if so any recommendations?

Philip, we have not had a chance to shoot any 7mm bullets. Our main focus was on the 6mm and 6.5mm bullets.

We hope to keep creating a “library” of bullet jumps, but we just need to clear out some current projects before we circle back to more shooting. Probably this summer we will start up again.

Hi Cal and Mark,

Fantastic research and thank you for sharing it for the betterment of the whole shooting community.

My thoughts on reading the 4 posts up to now were; “I wonder if you can apply the optimum bullet jump to a class of bullets…?”

What I mean by that is, can I take Scott Satterleys’ 6mm RDF data and apply it to my 6.5 and .308 calibre RDF bullets? The bullet should have the same (or very similar) ogive profile and form factor.

Similarly, can I also apply the Hornady ELD-M data for the 147 grain to my 140 or 143bgrn ELD’s? Again, the ogive and form factor will be similar…

My other thought was this, since Mark has financed all of this research up to now, would we as a community be able to send you a box of bullets and a tub of powder to help defray the costs and add to the database? I know it kind of depends on the calibre of rifles Mark is building at any one time, but I for one would really like to know what the research reveals for .30 calibre bullets. Whilst I do have more ‘efficient’ calibre rifles, I still love to shoot with my .308 and .300WinMag.

Obviously, you do not want to be inundated with random boxes of bullets, but perhaps you could select a few people who are willing to supply you with the requisite components. I’d be happy to spot you a box of Nosler RDF’s in either 140grn 6.5mm or 175grn .308. I have a LOT of them in the garage and they were pretty much useless to me since I could not get them to shoot accurately using conventional bullet jump distances.

Neil,

Thank you for your comments and it is very thoughtful for you to make those suggestions. I would not feel comfortable taking peoples components for this project, mainly because I need to do the shooting and testing when I’m free and available to dedicate my undivided attention. If I took bullets and components, I feel like it would put a lot of pressure to keep testing more and more (which I would love to do) but I’m currently not available to do it until summer time.

Back to your question about the class of bullets, I don’t think that is would work. A few quick examples are the Hornady ELD-M series of bullets. The 108 ELD-M bullets seem to like the .035″ range of bullet jump (which is what the .183″ freebore reamer gives Hornady factory loaded ELD-M ammo), the 140 ELD-M seems to like around .070″ and the 147 ELD-M and 143 ELD-X seem to like the .050″-.065″ range.

So even though they are in the same class of bullets, they all have their own specific jump ranges. Still so much to learn and we intend on learning as much as we can about bullet jump and what is happening. Through the years of shooting and testing, my comprehension of bullet jump has evolved and grown organically, driven by our findings. So we are going to keep moving forward, learning and evolving after each test and we will see where it takes us.

What an incredible research presentation. Being somewhat of a statitician myself, overlying all of these numbers over top of each other to identify a pattern shows that .045 seems to be the most statistically significant starting point for any of the caliber/weight presented. If the goal is to start with the lowest jump possible, that will give you the least vertical dispersion over the longest amount of throat-wear, .045 seems to be the best place to start.

While the sample size in terms of number of the number of different caliber/weight isn’t that large, it does seem to be consistent. I suspect that caliber “classes” will pattern similarly; in other words “You can expect X with .264 caliber bullets, and Y with .30 caliber bullets. We may luck out and find that X (.045 for example) is a great starting point for most any caliber/weight. I would be interested in assisting with some specific caliber/weight testing.

Thanks, Chad. I thought this was really interesting research too. It certainly seems to bring a new perspective.

I actually thought the same thing about somewhere around 0.040 being a good starting point, at least based on the data for all these tests. I plan to write a little more about that in the next post and talk more specifically about how we might apply this to load development on our own rifles.

When Mark and I first started talking about this, we were talking about the jump possibly being specific to caliber, but I think at this point it seems like there may be nuances to specific bullet designs. There may be commonalities between bullets of similar caliber/weight/shape, but I’m not sure we know enough yet to draw any meaningful conclusions about how these results can be applied to other bullets. For now I think the best path forward is simply to test it on your rifle, and see what you find.

I do think you’re right about something around 0.040-0.050” out being a good starting place if the goal is to give you the least vertical dispersion over the longest amount of throat wear. It doesn’t seem like any of these bullets showed consistent vertical much closer to the lands than that, and the ”largest node” or “sweet spot” was typically further than that … so if that’s the goal, you might be wasting ammo and barrel life if you start much closer to the lands, at least based on this data so far.

I appreciate the offer to help testing. I’ll let you and Mark talk through that. Either way, I appreciate the gesture and the thoughtful comments.

Thanks,

Cal