This post provides a primer on recoil, and then explains how I measured recoil, including the approach and specific equipment used. It also reviews the rifles and cartridges tested.

What do we mean by recoil?

I’ve read a thick stack of articles and white papers on this subject, and suffice to say we can get pretty deep in the weeds if we weren’t careful. But, I’m going to try to keep it simple and on point. For our purpose, recoil is the rearward kick we feel when we fire a rifle. I’m less interested in the esoteric mathematics-based models (although they can be helpful) … my primary goal is to quantify the shooter-felt recoil as best I can. Specifically I want to measure the force felt at the shoulder of the person squeezing the trigger.

Let me lay a quick foundation of the basic principles, which we’ll build on throughout this post. Recoil is a reaction force, according to Newton’s 3rd Law: “For every action there is an equal and opposite reaction.” That means for every force there is a reaction force that is equal in size, but opposite in direction. Or stated another way, in a closed system the total momentum is constant. Momentum is simply mass × velocity. Here is a diagram that illustrates this for our scenario:

The recoil force felt by the shooter has 2 components:

- Acceleration of the bullet

- Acceleration of the gases created by the combustion of the gun powder

#1 is easy to calculate, but #2 can’t be accurately calculated (especially when using various muzzle brakes or suppressors). Since the force felt by the shooter is a combination of those two forces, to get the full story on recoil, it must be measured instead of calculated. Professor Hall, a Mechanical Engineer at the University of Texas, explains:

“A standard historical method used to quantify gun recoil is to calculate the ‘recoil energy’ that a shooter absorbs when firing a gun. This calculated recoil energy usually takes into account the primary recoil only [#1 above] … While this method of quantifying recoil is useful, it ignores several factors that can affect the actual recoil force (felt recoil) transmitted to the shooter. Consequently, it would be very useful to be able to quantify the actual recoil forces experienced by the shooter to assess how they may be affected by such factors as secondary recoil [#2 above], recoil reducing devices, stock dimensions, bore geometry, and barrel porting.” (Hall, 2008)

I couldn’t agree more, professor.

How does a muzzle brake reduce recoil?

To reduce the reaction force coming backwards (i.e. recoil), we have to address what caused it. Of the two components that cause recoil (mentioned above), nothing can be done to reduce #1. If we want to launch a certain size bullet at a specific velocity, there will be equivalent momentum in the opposite direction. We may be able to spread that force out over time with a recoil pad or other technique, but it is coming … we can’t do anything to reduce #1.

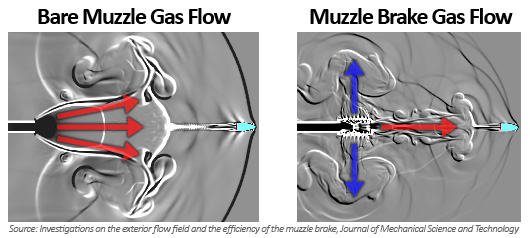

However, we can do something to reduce #2, which is the recoil related to the expanding gases. When you fire a rifle with a bare muzzle, all of the gases are expanding out of the barrel away from the shooter … which causes an equal and opposite force back towards the shooter. But, if we divert a portion of the expanding gases perpendicular to the bullet path, #2 is reduced. The diagram below shows this in action. The red arrows result in recoil. When part of the gas is diverted perpendicular to the barrel (blue arrows), those forces won’t contribute to recoil.

We can even go a step further by harnessing the energy of that gas to do work in our favor. When gas strikes the baffles of a brake and changes its direction, the gas is essentially pushing the rifle away from the shooter and reducing recoil even further. If we angle some of that gas rearward, it amplifies that effect even more. But, in the section on muzzle devices from Dr. Carlucci’s textbook, Ballistics: Theory and Design of Guns and Ammunition, he reminds us “Best design practice is to divert gases to the sides of the weapon, because rearward diversion could affect an exposed gun crew.” During my tests, a manufacturer sent me a prototype of a muzzle brake with 45° baffles back toward the shooter. It did offer amazing recoil reduction, but while testing that brake, a friend helping me with the tests caught some shrapnel in his side. It penetrated 2 shirts and caused a wound deep enough to see flesh. So there is clearly a downside to rearward deflection, but now we understand the effect that type of design can have on recoil.

What Contributes To Perceived Recoil?

Ultimately, I want to know what the difference in recoil is from the shooter’s perspective. I’m not interested in textbook theories, but the end-result of what I feel when firing a rifle. But, when we move to the subject of perceived recoil, we suddenly find ourselves in a strange mix of physics and psychology.

If we are firing a 140gr bullet at 2700 fps or 3200 fps, we can expect more recoil from the higher velocity. But according to Dr. Birch, an expert on this subject at the Impact Research Centre of Liverpool University’s Department of Engineering, “even when the velocity of two entirely different cartridges is similar, shooters may perceive a difference in kick. The explanation is usually found in the signature, which would have the same mean value but a completely different set of peak forces. Peaks in the signature contribute significantly to the difference in ‘feel’ between cartridges.”

Dr. Birch explains the force we perceive as recoil “varies considerably during a shot and is not just a simple push into the shoulder but a complex series of pulses occurring over a fraction of a second. Unfortunately, our nervous system is not sensitive enough to distinguish between these individual force pulses, which we perceive to be a single kick.” Here is an example of a recoil signature from my test that illustrates his point:

The recoil a shooter feels can vary by many factors, including:

- Physical build and stature of the shooter

- Shooting position, how tightly you grip the gun, how the rifle is supported, and how your body tenses in anticipation of recoil

- Stock design & fit

- Butt pad and clothing

- How many rounds you’ve fired that day (recoil can have a cumulative effect)

- Environmental stressors

Many of those factors are related to the connection between the weapon and the shooter. Felt recoil is largely dependent on the stiffness of that connection. If you were shirtless and firing a rifle with a steel buttplate that is pressed straight into your collar bone … that stiff connection is going to provide the full, unadulterated experience of the rifle’s recoil.

Would you be cold in a room that is 65° F (18° C)? Would you be hot at 80°? Some might be, and some might not be. Likewise, a shooter’s ability to tolerate recoil is based on personal perception. It was once widely believed that a 30-06 was the largest cartridge a man could shoot without developing a flinch. Many might argue that point today. (Read a good article by David Petzal on this.) This isn’t a test of manliness, but simply what you’re personally comfortable with.

The human factor simply isn’t calculable, so there doesn’t seem to be a way to accurately measure perceived recoil directly. But, that doesn’t mean we can’t still do something to gain insight into this area. Since we can’t directly account for those other factors, we can take an “all things being equal” approach for those elements, and instead try to quantify the percent difference in recoil reduction muzzle brakes provide. So even if a shooter had a rifle that didn’t fit them well, and they had a bad shooting position, and they’d already fired 100 rounds that day, and the rifle didn’t have a butt pad (ouch), if we measured a 20% decrease in recoil at the rear of the rifle with Brake A and a 50% decrease with Brake B … we could say with some confidence they’d experience less recoil with Brake B. Now, we could not say whether it would hurt, or even have an absolute value to quantify what they’d feel. But we’d know that with all other factors being equal, Muzzle Brake B would reduce the recoil felt at the shooter’s shoulder.

Does total force or peak force matter more?

When we say “reduce recoil,” what exactly are we talking about? That gets us to a big question:

I’ve asked a lot of sharp guys this question, and there seems to be proponents on every side. It is definitely not a straight-forward question, and there doesn’t seem to be an established industry standard.

Total “Size” of Force (i.e. Impulse or Momentum)

If you said total “size” of the force matters most, you’re in good company. Many take that stance. When I say the total “size” of the force, I’m referring to the area below the curve when you graph force over time (like the diagram above). In physics, this is referred to as impulse, which is simply the change in momentum. That is what you’d be quantifying if you used a classic ballistic pendulum, or a more pragmatic alternative I’ve seen is mounting a rifle on the sled, firing it, and measuring how far it moves. But, a rifle could move to the same point slowly or quickly, and while the size of the impulse may be identical … the perceived recoil could be very different.

If you said total “size” of the force matters most, you’re in good company. Many take that stance. When I say the total “size” of the force, I’m referring to the area below the curve when you graph force over time (like the diagram above). In physics, this is referred to as impulse, which is simply the change in momentum. That is what you’d be quantifying if you used a classic ballistic pendulum, or a more pragmatic alternative I’ve seen is mounting a rifle on the sled, firing it, and measuring how far it moves. But, a rifle could move to the same point slowly or quickly, and while the size of the impulse may be identical … the perceived recoil could be very different.

This is often evident when people describe the felt recoil of a particular gun/cartridge as “soft” or “sharp.” Soft recoil is spread over a longer amount of time, where sharp recoil occurs over a shorter amount of time. Pistols are a great example: Some guys prefer the recoil of a 45 ACP over a 40 S&W. The 45 produces more recoil (i.e. impulse), but the recoil isn’t as sharp as a 40. They describe the felt recoil of the 45 as “more of a push,” and the 40 as “sharp and snappy.”

The diagram below shows two recoil forces that have the same total “size” of force (area under the curve), but would feel very different to the shooter. So we’re saying the blue area is roughly the same size as the red area. While it may be true that the cumulative “size” of the force is the same for both of those shots, the perceived recoil of those two recoil signatures would be very different.

Think about it like this: I have a bunch of beach sand in a pail. I pack it, flip the pail over, and make a little sand castle, like #1 shown below. But then, I push that sand castle over, and now it looks like #2. In both scenarios, it’s the exact same amount of sand. I didn’t add sand or take any away. They look quite different, but all that changed is the shape. The force curves in the diagrams above are similar to the sand castle … one is just pushed over, but its same “total amount of force” or impulse.

A recoil pad actually has this effect, as does a gas operated semi-auto. Both spread the recoil out over time, but they don’t change the total amount of force. They just push the sand castle over. They “allow the momentum exchange between the gun and shooter to occur over a longer period of time, reducing peak recoil forces,” explains Professor Hall.

So while total “size” of the force (otherwise known as impulse or change in momentum) certainly affects perceived recoil … it doesn’t seem to give you the full picture, because if we spread that same amount of force out over time we may perceive that as less recoil.

Peak Force

Many believe the peak force is what most closely correlates to perceived recoil. In fact, a team of mechanical engineers at Cal Poly clearly stated: “The amount of ‘kick’ or push against the shooter is determined by the peak force.” They’re saying the highest point of the line on the graph is most indicative of whether someone would say the recoil of a gun was more or less than another gun.

Dr. Birch seems to agree: “It is likely that a significant contribution to any discomfort and injury is due to the peak force in the early stages of the reaction. This catches our nervous system off guard well before our reflex has time to operate and can set up serious shock waves in the arms, shoulder and back; high-speed cine recordings confirm this.”

But, peak force alone doesn’t seem to tell the full story either. Two rifles could have the same exact peak force, but feel very different to the shooter. In the example below, if recoil from the blue curve hurt, then the red one might make a grown man cry … yet both have the same peak force.

So if you used a force gauge that only measured the peak force, that wouldn’t give you the full story either. It seems to be some combination of the two, so you can’t just measure one or the other. To ensure we’re making a valid comparison, we’ll need to capture the full recoil signature.

The Test Equipment & Setup

I looked at a lot different equipment setups, from academic white papers to creative and pragmatic DIY approaches on YouTube. I can appreciate both. But, as we saw above, to get the full story, you really need to capture the full recoil signature, not just the total momentum or peak force. The systems shown to the right are a few examples of setups I uncovered that were able to do that.

I looked at a lot different equipment setups, from academic white papers to creative and pragmatic DIY approaches on YouTube. I can appreciate both. But, as we saw above, to get the full story, you really need to capture the full recoil signature, not just the total momentum or peak force. The systems shown to the right are a few examples of setups I uncovered that were able to do that.

The problem is the recoil event is very short, lasting only about 10 milliseconds. If you were only able to record a few readings in the recoil cycle, you could easily miss the highest point of the peak. I wanted equipment capable of recording at least 100 force measurements in that time frame. That recoil force can also be in excess of 1,000 pounds. That is a lot of force, in a very short amount of time … which translates to expensive equipment.

I met several interesting people with experience measuring recoil, mostly for government projects. One group measured the g-force acceleration experienced by a scope under recoil. They attached an accelerometer to the rail of the rifle, which I considered. But, remember my primary goal is to quantify the shooter-felt recoil as best I can. Specifically I want to measure the force felt at the shoulder of the person squeezing the trigger. So I preferred to measure recoil at the butt of the rifle, which gets me closer to what I’m trying to quantify and it will include any effect from recoil pad, stock design, and other recoil reduction devices.

Unfortunately, there aren’t any pre-packaged solutions for this. After reading other research, I created the rough mockup below and sent it to a lot of smart engineers to verify I was headed in the right direction. Then I contacted several sensor companies to get recommendations and quotes for a system that would meet these requirements.

This design minimizes moving parts. As the team of engineers from Cal Poly explains, “less moving mass … will lead to more accurate force results.” Professor Hall also reminds us “It is important to note how the degree of restraint provided to the firearm … affects gun movement and the measured recoil force.” So I didn’t want to restrain the firearm in any unnatural way. I used two shooting bag, similar to the Cal Poly team: “This final design, unlike the concept design, incorporates two shooting bags instead of having the rear of the stock on a linear precision rail. It was determined that the friction force from the rear shoot bag is negligible…” This setup also closely mimics a precision shooter using a rear bag, which is the scenario I’m trying to recreate.

Sensors & Electronics

It was surprising how low-level I had to get to create this system. I ended up neck-deep in technical specs, doing all kinds of calculations, and even discussing custom parts and cables. It’s no wonder most manufacturers don’t have equipment like this … it was a lot of work to design and implement!

I learned most force gauges can’t come close to capturing data at the speed I was looking for. In fact, a few people claimed recoil happened so quickly that you couldn’t accurately measure it. But, I’m stubborn … so I pressed on. It turns out you can use a piezoelectric sensor, which generates a voltage when compressed. These sensors have an extremely high natural frequency.

I learned most force gauges can’t come close to capturing data at the speed I was looking for. In fact, a few people claimed recoil happened so quickly that you couldn’t accurately measure it. But, I’m stubborn … so I pressed on. It turns out you can use a piezoelectric sensor, which generates a voltage when compressed. These sensors have an extremely high natural frequency.

Quotes for setups were all over the map, ranging up to $5,000+. I ended up talking to a rep at PCB Piezotronics, who had experience building a similar setup to measure recoil for a U.S. military project. The system we ended up building was also similar to what a team of mechanical engineers from California Polytechnic State University designed for Weatherby in 2013. They posted a detailed project summary, which you can view here. They explained, “In order to remain competitive, Weatherby needs an accurate method for measuring the recoil force of their rifles, shotguns, and ammunition. Currently no commercial product has been located for testing their guns, so no methods are being employed; however, it appears that other firearm manufactures have this data, so custom systems exist.”

Here is the set of equipment I ended up using:

I have a piezoelectric force sensor that can measure up to 5,000 lbs. of compression force in 1 lb. increments. The sensor is connected to a signal conditioner (amplifies signal and preps it for digital conversion), and that connects to what is referred to as a DAQ (Data Acquisition) unit. Some high-end DAQ devices have a signal conditioner built-in, but if you’re value-engineering, you can save money by getting separate devices. The result is the same. The DAQ device converts the analog signal from the force sensor to a digital signal and passes that to a computer through a USB cable. The DAQ device I selected is able to capture up to 48,000 samples per second. On the computer, I used DAQami software to capture the force readings and save them to a file. The post-processing and analysis was done by custom software I personally wrote.

The force sensor was professionally calibrated by PCB Piezotronics before my tests to ensure it accurately measures force data.

Custom Test Fixture

I designed and custom-made a test fixture that will hold the rifle and sensor. It was a heavy, solid design using 2” square tubing made from of thick, 11 gauge steel. I fully welded all of the joints. Honestly, its over-the-top … but I didn’t want any possibility of deflection skewing the results.

I tapped the back plate of the test fixture so the force sensor could be screwed directly into it (following the manufacturer’s recommendations). A mounting stud was included with the PCB sensor with 10-32 UNF-2A threads.

I tapped the back plate of the test fixture so the force sensor could be screwed directly into it (following the manufacturer’s recommendations). A mounting stud was included with the PCB sensor with 10-32 UNF-2A threads.

Part of the over-the-top strength of the steel base is for weight. As the Cal Poly team explains: “Since there is minimal upwards force, the weight of the system should be enough force to keep the system from lifting upwards … Rifles are designed to shoot accurately, which means that the rifles primary motion is in the direction of the barrel axis. This system is designed to record the backwards recoil force along this axis using the force sensor, meaning that the back plate of the system is going to be experiencing most of the force from the discharge; hence, the safety of the back plate is of utmost importance. The front of the rifle stock may “kick” upwards; however, this force is not substantial enough to be of any concern, as it will not overcome the weight of the system.”

Butt Holster

If we just put the butt of the rifle directly against the force sensor, the recoil pad will deform under recoil and allow the force sensor to dig in at a single point. This could skew the readings or make them inconsistent. That type of setup also wouldn’t be recreating a shooter with the recoil pad on their shoulder. Once again, I was inspired by the design of the Cal Poly team, and here is what they said on the subject:

If we just put the butt of the rifle directly against the force sensor, the recoil pad will deform under recoil and allow the force sensor to dig in at a single point. This could skew the readings or make them inconsistent. That type of setup also wouldn’t be recreating a shooter with the recoil pad on their shoulder. Once again, I was inspired by the design of the Cal Poly team, and here is what they said on the subject:

“The butt of the gun is placed against a piece of HDPE plastic that is secured in place with Velcro. This is to ensure that that the sensor is able to utilize the damping of the entire butt pad and measure the force that the shooter will actually feel. The plastic piece also provides a flat surface to contact the force sensor, which is located directly behind the mold and is attached to the back plate of the system. The flat surface will make sure that the force sensor does not encounter a bending moment, which could harm the sensor.”

Like Cal Poly, I used HDPE (High-Density Polyethylene), which is a plastic with a very high impact strength and great durability. I custom-made this from a 1″ thick block of HDPE I bought off Amazon. I used 1″ webbing straps with ladder-lock buckles to attach the holster to the stock. This setup was very flexible and worked well on every stock I tried it on.

The total cost of this recoil test system was around $1,500 (including hardware, software, tax, shipping, etc.).

It was found to be sensitive enough to measure recoil force differences among different factory loaded ammunition, and differences in recoil force of different firearms shooting the same ammunition.

Here is a what the whole setup looked like:

Here is a quick video of me running through a series of measurements with this test equipment with a specific rifle and muzzle brake.

[youtube http://www.youtube.com/watch?v=j8JhsTT_JRs]Test Cartridges

I tested on a range of rifles and cartridges in 6mm, 6.5mm, and 30 caliber, which represent the most popular calibers for precision rifles (based on muzzle brake sales). Let’s start by looking at the cartridges used in the tests:

The 6XC, 6.5 Creedmoor, and 308 Win are all mid-sized cartridges with a very similar powder capacity. They only vary by caliber size. I used popular bullet weights in each of the cartridges, which in the precision rifle world are typically the heavier bullets for each caliber. These cartridges will help us see how bullet weight and caliber-specific muzzle brakes affect performance.

I also tested with a 300 Norma Magnum (not to be confused with the old 308 Norma Mag). This is a newer cartridge that has been gaining popularity since Berger’s release of 230gr Hybrid bullet a couple years ago. The ballistics of this cartridge can challenge the 338 Lapua Mag at long-range (see Todd Hodnett’s comparison). The 300 Norma Mag cartridge has 11% more powder capacity than the 300 Win Mag, and represents one of the largest 30 caliber magnums. So it will help us see what happens to muzzle brake performance when you significantly increase powder charge and bullet weight.

I used match ammo for all of the cartridges, because I wanted to minimize shot to shot variance of muzzle velocity. The recoil measurement equipment is extremely sensitive, and I didn’t want factory ammo with a 20+ fps standard deviation in muzzle velocity to skew the results. I wanted the most consistent data possible, which meant using match-grade ammunition for all of the tests.

Test Rifles

I strategically selected the rifles I used for the recoil tests, because I wanted to represent a wide range of stock designs and rifle weights. Here are the rifles I tested with:

The 6XC is one of my personal rifles built by Surgeon Rifles, and I covered that rifle build in-depth in a post last year (view that post). It is in a Manner’s 100% carbon fiber TF2 Tactical Folder stock. It has a thick 24” MTU barrel, and was the heaviest rifle used.

The 6.5 Creedmoor was a Surgeon Rifle one of my good friends let me borrow for the tests. (Thanks Rick!) It is in the very popular McMillan A5 tactical stock. It has a fluted 22″ Heavy Palma barrel, and the weight represents a typical precision rifle. Many rifles used in the Precision Rifle Series have weights similar to this rifle.

The 308 Win rifle I used is not necessarily a precision rifle, but it represents something most people would be familiar with. It is a standard, budget-friendly 308 rifle. This particular one is a Savage Axis SR 308 Win. I consider it my baseline for comparison. While not all of my readers have had the pleasure to shoot a really high-end precision rifle (like the other 3 rifles shown), almost everyone has fired a rifle similar to this. So by using it in the tests, it can help give some context for the amount of recoil we’re talking about. This rifle will also help us understand how the rifle weight plays into the recoil equation, and how that affects muzzle brake performance as a percentage of recoil reduction.

Lastly, the big 300 Norma Mag rifle was another rifle one of my good friends let me borrow for the tests. (Thanks Bob!) This rifle is in the popular Accuracy International AX chassis, and has a 27” Lilja Palma 30B contour barrel (similar to a Medium Palma contour). It’s also a heavier rifle, but represents what is typical for these types of large magnums. They can be unpleasant to shoot if you drop the weight.

References & Further Reading

If you’re interested in digging deeper into the stuff covered in this post, here are a few of the best resources I found in my research. Most are available for free online.

- Birch, Dr. Robert. “Recoil – Frequenty Asked Questions.” Clay Shooting Magazine (2001).

- Canfield-Hershkowitz, Benjamin, Trevor Foster and William Meijer. Rifle and Shotgun Recoil Test System. Poly Tech Mechanical Engineering Senior Project. California Polytechnic State University, 2013.

- Carlucci, Donald and Sidney Jacobson. Ballistics: Theory and Design of Guns & Ammunition. CRC Press, Taylor & Francis Group, 2008.

- Hall, Matthew J. “Measuring felt recoil of sporting arms.” International Journal of Impact Engineering (2008).

- Hokin, Samuel. “Gun Recoil.” BSharp.org: The Physics of Everyday Stuff.

- Lee, Joon-Ho, et al. “Experimental Performance Analysis on Recoil Pad for Reducing Firing Shock Force.” NDIA International Infantry & Joint Services Small Arms Systems Symposium. 2008.

- Nailon, Larry. “A Look At Recoil.” Clay Shooting USA (2006).

- Richmond, Michael. “Force, Momentum, and Impulse.” Rochester Institute of Technology Physics Class Lecture Notes.

- The Physics Classroom. “Momentum & Impulse Connection.” The Physics Classroom.

- US Army Materiel Command. “Engineering Design Handbook – Gun Series – Muzzle Devices.” 1968.

- Zhang, Huanhao, et al. “Investigations on the exterior flow field and the efficiency of the muzzle brake.” Journal of Mechanical Science and Technology (2013).

Other Post in this Series

This is just one of a whole series of posts related to this muzzle brake field test. Here are links to the others:

- Field Test Overview & Line-Up: Overview of how the tests, what brakes were included, and which were caliber-specific.

- Recoil Reduction Results: Let’s get right to the meat!

- Recoil Primer, Test Equipment & Rifles: Explains how I tested, and what equipment and rifles were used.

- Results for 6XC and 6.5 Creedmoor: Recoil results for the mid-sized 6mm and 6.5mm rifles.

- Results for 308 Win and 300 Norma Mag: Recoil results for the mid-sized 30 caliber and large magnum 300 rifles.

- Summary: Overview of recoil results from all rifles, and overall ratings of each muzzle brake.

- Ability to Stay on Target: Lasers and high-speed cameras were used to objectively quantify how well each muzzle brake helps you stay on target through a shot.

- Sound Test: A high-end sound meter was used to measure how loud each brake was to the side of the rifle and at the shooter’s position behind the rifle.

- Muzzle Blast & Ground Signature: High-speed videos were shot of each brake to show the direction of the muzzle blast, and the impact that could have on the shooter.

- Overall Summary: Putting all the results together in a summary that is easy to take in, and do side-by-side comparison, allowing you to draw your own conclusions on what muzzle brake is best for your situation.

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

Wow! Why didn’t you teach my college physics class? I probably would’ve enjoyed it! Thanks for all your effort. I enjoy reading all of your article.

HA! It took a lot of effort to write this. I tried to make it approachable by anyone, but without watering or dumbing it down. That kind of writing is tough. I also had several really sharp engineers look over the first half before posting, and they had a lot of good input for me. Hopefully it helps clear up a little of the muddy water that has plagued this topic in the past, and at least establish some context for the results I’m about to publish.

Thanks for the encouragement!

Cal

awesome work! as an engineer it makes me happy to see how much you’ve put into your system. I think the finer details, such as using a strap to hold the system against the ledge prove that point. There are two things I would like to suggest, keep in mind both are minor at best.

1. apply pressure to hold the stock against the sensor. most shooters should be loading the bipod anyway and it will impact the data. if you preload, then it reduces the distance the gun can accelerate before hitting the shoulder, or sensor. its why when shooting larger cartridges we really dig the gun into our shoulder.

2. you should weigh down all the rifles to be the same weight. youre right in that in an ideal system it wont make a difference, and since were not comparing cartridges but breaks, its not important. But in a real world system, where the stock, pad, sensor, metal frame all compress under load, the mass does make a difference. and it would open up the possibility of comparing cartridges.

Its important to remember that fluid flow isn’t always linear. reducing recoil might be disproportionately harder on larger calibers.

but those minor details aside, this is great work youre doing! you’ve really found a good home between science and guns. the amount of work you’ve put in to walk through every detail is beyond stellar. I look forward to the results!

Thanks, Adith. Yeah, I learned a lot during this test. The tie-down strap is just one example of that. I actually ran through the entire test (every rifle and every muzzle brake) at least twice, and some of them 3 times. I would find a better way to do something or make a tweak that made the results more consistent, and since I can’t leave good enough alone … I’d redo all the tests. I originally did all the tests on concrete benches, but it turns out the that if I used a different bench you could see differences in the harmonics of the thick 3″ steel pipe that concrete bench was resting on. How crazy is that?! So I eventually moved to the concrete slab, and that made the readings more consistent. And also the test fixture wants to move away from the concrete on each shot. If it isn’t in the same position each time, that can slightly skew the results … so the tie-down fixed that.

Luckily I had another a really smart engineer, Zak Smith, come down about half-way through the testing, and he had a lot of good questions and input. But … that meant I got to run through all of the tests again after he left. I burned at least 1,000 rounds of match-grade ammo in the recoil portion of this test alone! (Read $1000+ just in ammo)

Having said all that … this test in the books. I appreciate your input, but I think I’d have a nervous breakdown if I had to go setup that recoil system one more time! I’ve made many trips out to the range with it since the first part of April.

For #1, the PCB rep actually said you shouldn’t preload the sensor. It would be very difficult to preload it with the exact same amount of pressure each time. He suggested that I ensure the rifle is right next to the sensor, but not preloaded … so I followed his direction.

For #2, I think some variance in the weight is very real-world. Remember, this is a field test … so I try to use real rifles in as real of scenarios as possible. Although I have thought about loading that 308 down in 1 pound increments up to something like 20 pounds to see what the effect is on recoil. I know we can calculate that, but I just wonder if we’d find anything interesting. I haven’t done it yet … but I might at some point.

I plan to present most of the data as a percent reduction in recoil, which takes the weights out of the equation for the most part. It at least doesn’t seem to make as significant of a difference as you might think.

As always, thanks for the input. You’ve definitely got a sharp eye for detail, and I appreciate the encouragement from an engineer. This post was A LOT of work, because I put a ton of effort into trying to explain something really technical in a way that is approachable for non-technical people. The next few posts will be the fun part.

Thanks,

Cal

Honestly, like i said, those were probably super minor if anything. Especially considering that youre doing this on your free time with your own money, I have very little grounds for complaints haha.

If you need any help crunching numbers or data, let me know!

Cal, Thanks for doing and sharing all the details, your site is becoming one of my favorites.

Interesting Zac joined in, there’s a reason I own four of his cans. The last one cleared Form 3 on Thursday.

Yeah, I emailed Zak (like all the other manufacturers) to see if he wanted to include one of his muzzle brakes in the test. I thought it’d represent the basic TOMB (Thread-Over-Muzzle-Brake) design that so many suppressor companies use (SAS and a few others have a similar design). It might give us insight into how much performance you would be giving up by going with the convenient option of using brake that works with your suppressor instead of swapping it out with a dedicated suppressor.

When I explained what I was planning to do, he was intrigued. I had actually extended and invitation to several of the manufacturers to come down and watch the tests if they thought it’d be helpful. A few said they might, but Zak was the only one that ended up down here. He drove several hours (on Mother’s Day weekend) because he wanted to get some recoil data on his new Ultra series of suppressors. In fact, he wanted to see my whole recoil test system setup so that he could go back and build something to help them with future R&D.

Zak is an engineer, and naturally data-driven. He asked a lot of great questions, and honestly made this whole test even better. When I knew he was coming down, I asked him to bring along his super-expensive sound meter and testing equipment. I had originally hoped to measure the loudness of each brake, but you really need specialized equipment to do that correctly. A cheap, OSHA sound meter is not going to give you accurate results, and I’d rather not publish anything on it than publish data that is misleading. But … Zak is a suppressor manufacturer, so I knew he had a high-end, mil-spec, calibrated sound meter, and the professional expertise to know how to use it. SWEET!!!

So one day we ran through all the muzzle brakes on the sound meter in a couple different ways, and then ran through all of his suppressors on my recoil test system. It was a lot of work, and a lot of fun. Conversations on days like that are the biggest reason why I do stuff like this. Talking with super-sharp guys like Zak and learning from them, and being challenged by them … is such a treat. I’m honored to get to have conversations with guys like him in this industry. You can learn so much in just a few minutes. I know not everyone has that opportunity, and I’m grateful this platform has provided that for me. I really consider that my biggest form of payment for all the work I put into this. I’ve met some really interesting people, and learned so much. I’m in debt to them.

And after all that testing … I’m about to buy my 2nd Thunder Beast can. Just in case it sounds like I’m a fan boy, I don’t get any kind of discount or special treatment from those guys. I’d pay exactly the same amount for it if I’d never met them and was just some random guy … but dang they’re good. That new Ultra series is something special. I’ll post the data I recorded on them at some point … but they’re something special. If I thought there was a better suppressor out there, I’d buy it. Sorry, Zak. Your product has to stand on it’s own. I don’t play favorites. Zak understands that, and while I don’t know him real well … he actually seems like that kind of guy himself. I believe in the precision rifle suppressor market as of today, they’re the cat’s meow. Someone will leapfrog them at some point. That’s just how this industry works. But for now, I’m ordering an Ultra-7 suppressor!

Sorry for the long rambling! Might be WAYYY more than you wanted to know!

Cal

Felt Recoil ? My standard 30-06 is said to have 16 pounds of “felt recoil” …. My 460 Weatherby Magnum is said to have 116 pounds of “felt recoil”. Whats the formula to turn your peak readings into “felt recoil” ? Or am I addressing such incorrectly present and past ??

Eager for the results…regards from the Panhandle.

Stay safe !

There is no calculation for “felt recoil.” I’m assuming you are talking about recoil energy, which actually has units of “foot-pounds” … not pounds. It’s very different. And I’m assuming you’re referring to calculated recoil energy. If you’ll look towards the top of the article, you’ll see a quote from Professor Hall on this:

The question “Whats the formula to turn your peak readings into ‘felt recoil’?” is kind of what this whole article was about. You might read through it again. If I am misunderstanding something, please let me know.

Thanks,

Cal

Nope…. I stand corrected. Actually printed out the article for my read file at work tomorrow. Will read versus scan….:o)

Thanks for your time and the excellent work you do here.

Yeah, sorry it’s so long-winded. I tried to delete as much as I could! It’s just a complicated topic with a lot of misinformation out there.

Thanks,

Cal

Cal – another incredible post. How on earth do you even dream up these projects?? 🙂

Ha! I was thinking about this one for a long time. I was dreaming about it with Jason from JEC over a year ago. While muzzle brake may seem like a little minor accessory … I couldn’t quit thinking about it, because it just seemed like nobody had brought a scientific approach to that area. At least not in the public sector. I know there has been some government projects, and there may be manufacturers with some data … but nobody has published anything the shooting community could benefit from. I had to do this test to get it out of my head!

This post took a ton of effort and time, honestly. Way more than normal. I really tried to make a very technical topic approachable by just about anyone. Hopefully I was able to do that. It will make the results more meaningful if people can understand this. It will also educate us so that we’ll question manufacturer who make wild claims like “70+% recoil reduction” which is what is published on the OPS website right now.

Thanks for the encouragement!

Cal

Thanks so much for all your great articles. I am a writer for various magazines and I can’t imagine the number of hours you put into this. Great job and keep them coming. You have a good way of explaining everything that makes it easy to understand.

Wow, Don. That means a lot coming from a pro. I do put a lot of effort into it.

Thanks,

Cal

Cal:

Thanks for taking the time to do these tests and write them up in such a methodical and well explained manner. I appreciate your work and look forward to your results, as well as your future projects.

Thanks!

Cal, It would’ve been nice to know about this test in advance so that we could’ve sent in some brakes, but it’s allgood.

It is nice to see someone trying to get more “seat of the pants/kick to the shoulder” data, but one thing that a LOT of very smart people forget is that the human body is soft. Not trying to critique your methods by any means, but you’re attempting to assign hard numbers to a soft science. I’m actually throwing this info out there to help explain why some people may end up saying that your results may not match real world “feel”(won’t know until results are posted). 1. The buttpad isn’t the only thing that will compress before “kick” is felt, the soft tissue of your shoulder will compress more than you realize. fix: 1″ of spenco/anatomic gel between the butt pad and cradle, preload the buttpad to the gel/cradle with approximately 10lbs of force (typical amount of pullback into shoulder for average shooter), but do not preload the sensor(for reasons you’ve mentioned). This matters because on some rifle/brake/ammo combinations your test rig will show significant recoil numbers but real world felt recoil will say otherwise because the brake is efficient enough with given combo that rearward momentum of rifle will be arrested/reversed before recoil is even noticed as a “kick”.

2. Mass of rifle vs mass+velocity of bullet vs length of barrel vs Mass+velocity of gases. Things that matter (but you’d spend many thousands more on ammo to quantify). While testing a competitors brakes vs ours, we found that on rifle A(heavy rifle) with heavy bullets vs rifle A with lighter bullets , ours was more effective(slightly) with the heavy bullets and theirs had the edge on the light bullets , but on rifle B(lightweight rifle) with heavy vs light bullets, the results were almost exactly opposite. And this can be attributed to kinetic energy of rifle vs kinetic energy of gases in the given combo.

3. Muzzle brakes 101, a brake is more like a parachute than a rocket. True that most brakes are designed as much by marketing guys as engineers, we are one of the few companies that base our brakes on scientific rules instead of theories and guesses(but for 5+years Brakes is all we did). Most people in the industry insist on thinking of burnt powder merely as a hot steamy jet of “air” , when in fact the powder that weighed 46gns before it was burnt, STILL weighs 46gns(and when the bullet gets out of its way, moving at 10,000+fps), and the more effective you are at giving that 46gns of mass something to slam into, the more effective and faster you are going to be at arresting the rearward momentum of the rifle.

All of this being said, I applaud your effort and look forward to the data(even though we’re not included, lol ).

But in the end, if given the opportunity, a shooter should try as many brakes as possible, and buy the one that THEY think works the best (which is why we offer demos at matches and ranges wherever we travel),

because in the end its like trying to quantify how much better coke vs pepsi vs mtn dew vs drpepper tastes.

Sincerely,

Jeremy Kahn

President/Owner: Kahntrol Solutions

Sorry, Jeremy. If I’d given an open invitation for muzzle brakes, I’d have received 100+ and wouldn’t have been able to complete the test. It just wouldn’t have been feasible, because I do this all in my spare time. I haven’t heard of your design, but it does look different from what most people are doing … so I appreciate that. I’ve never been a guy that just wants to do what everyone else is doing. I appreciate creativity and innovation.

Now to your comments … You have some good points, but I’m not sure how much they apply. Before I address them, I’d like to re-emphasize this paragraph from the “What Contributes To Perceived Recoil?” section:

1) Yes, there is soft tissue involved. When I first started testing, I put a layer of neoprene inside the butt holster on some of the tests to approximate that soft tissue (in both thickness and hardness). So I originally thought the same thing. But, that soft tissue simply spreads the recoil force over slightly more time. It’s like a light wind blowing over the sand castle. And it would be like a light wind blowing over the sandcastle in an identical way for every scenario (for every muzzle brake, as well as the baseline bare muzzle). So if we said the muzzle brake reduced impulse by 30% and peak force by 25% … that would likely be true if there was soft tissue there in our test or not. The % reduction would be virtually identical in both scenarios. The actual values would be different … I totally get that, but we already established that it would be impossible to get absolute values to quantify felt recoil anyway. For one thing, you couldn’t accurately reflect the amount of soft tissue for all shooters: some people don’t have a lot of meat on their bones, some have a lot of fat, some have more muscle, some pull the rifle into their shoulder very firmly, some less firm, etc. But, it’s like I was saying in that paragraph … we can take an “all things being equal” approach for factors like that. The alternative is to just not do any type of data-driven test because we can’t perfectly recreate the full scenario. Is that a better solution? I know you probably go out to the range and ask people if your brake feels better than another one … but that approach has issues too. 1) You are sitting there with them and your presence will skew the results. Acquiescence Bias will come into play. 2) People are terrible at comparing things side-by-side, especially things like short bursts of high pressure that are separated by seconds or minutes. Our senses and memory just aren’t well equipped to make those kinds of comparisons. I’m not saying it is a useless approach, but maybe it shouldn’t be our only approach … and historically speaking, it has been for most people. I think this data-driven approach can complement that and bring a different (and more objective) view. I hope you can see the value it offers.

2) That’s very interesting. I’d love to see your test data on that.

3) Thanks for the Muzzle Brake 101. 😉 I totally understand what you’re saying. It’s the conservation of mass. I may be missing the point you’re trying to make there.

I do love the idea that you give people a chance to try your product before they buy it. That shows you have a lot of confidence in the product, and want to let it speak for itself. And once again, sorry you weren’t included. I do this all for free in my spare time, so I just can’t test every brake out there. I do disagree on this being a “coke vs pepsi” thing. We can make empirical comparisons for several aspects related to performance. It’s not just a personal preference thing.

I hope you can see the value in these tests, but I don’t want to argue with you about it either way. I feel like I’ve laid out my case pretty clearly … and a lot of people seem to appreciate it, including some of the leading experts in the industry. If you can’t see value in it, I’ll give you a full refund and won’t make you read the rest of the tests.

Thanks,

Cal

Cal,

I totally understand the lack of open invite, I wasn’t criticizing on that point, My apologies if it sounded as such. I also want to applaud you for your time, effort, and thoughtfulness in your tests and writings, you do go further than many do, and do appreciate the value in it.

You do admit in your article, that the data compiled is not a perfect apples to apples measure of felt/perceived recoil, and my suggestions were not meant to detract from your methodologies in acquiring empirical data. The gel/foam thoughts(that apparently we both shared) would be irrelevant if there were some way to correlate the peak forces and peak impulses relative to rifle position from its starting point in a free recoil scenario, because depending on shooter and hold firmness, the distance the rifle travels and where it is in relation to the shoulder at peak pressure will weigh heavily on “perceived” recoil. This brings up the barrel length/mv/bullet weight/rifle weight issue that I mentioned. Common knowledge should tell us that a brake does absolutely NOTHING until the bullet exits the muzzle, and depending on the aforementioned factors, it may be too late depending on the rifle/cartridge combo (perfect illustration would be a shotgun firing a 1oz slug at 1350fps from a 29″ barrel, a brake may bring the muzzle down, but the shoulder is already hurting by the time the load exits and the brake can go to work). This is why “effectiveness” can be different when you start comparing different rifle load combos with different brakes, it needs to be done, but sometimes the data will conflict between the tests(whether it be free recoil, weighted recoil, peak impulse, peak pressure ,etc), and your testing I believe will show this to be true.

The conservation of mass point was that the redirection of gases is actually a side effect of a brake working as opposed to the common belief that the redirection is the reason a brake works(as opposed to barrel porting which is “venting a high pressure closed system through orifices to direct or redirect pressure”).

Again, Please don’t take any of this as trying to contradict or invalidate any of your work or findings, You do better than most. Also, on much of this I’m probably preaching to the choir, but I’m just attempting to point out to the readers why, as good as your methodologies are, and as sound as your empirical data may be, that Perceived recoil is not the same as measured recoil(which you also point out) and there are many immeasurable factors that go into perception.

On the coke vs pepsi thing, I was referring to the quantifying of perception, not the empirical data, because a fat guy like me with fat/padding on his shoulder is going to perceive less recoil from a 300wm that only free recoils 2″ thanks to a brake than a scrawny stick like my son is going to perceive from a 243 that free recoils 1″ with a brake, even though the empirical data will most certainly show otherwise.

Keep up the good work, and I’d love to chat with you at some point.

Sincerely,

Jeremy

Nicely done, a lot of good stuff to think about. Can’t wait to see the results.

Thanks, Aaron! I think it’ll be eye-opening. There were a few surprises for me. I’ll start hammering it out!

Thanks,

Cal

I was wondering if any tests were ever done on the Lantac Dragon brake…I’ve not found any that did better than this one, however it was $139!!

Hey, Jerry. I haven’t done any tests on that brake. That is actually the first time I’ve heard of it. But I’m sure there are a lot of good brake designs out there. Glad you found one you like.

Thanks,

Cal

Hi Cal, thanks for the most informative articles!

We are having a discussion about perceived recoil on one of the our local forums in South Africa about perceived recoil and the difference the type of powder makes when launching the same weight bullet from the same rifle at the same speed.

I experienced in my 9.3×62 that with a slower burning powder, although I have to use more powder, I get less recoil. Laying in bed and thinking about it I could come up with the explanation that the peak recoil force is different. To describe it you can look at the acceleration of the rifle and doing some calcs in Quick Load showed exactly this.

S355 is the slower burning powder. Both projectiles is launched at 2350 fps

https://dl.dropboxusercontent.com/u/37019857/Geweer%20fotos/9362recoil2.png

Quickload also shows the peak force of gun recoil has the same trend I experienced with my rifle in terms of felt recoil although the energy and momentum figures are reversed again.

https://dl.dropboxusercontent.com/u/37019857/Geweer%20fotos/9362recoil3.png

Would you agree with this?

Most articles I’ve read point to a faster burning powder generating more recoil. In fact, one of the articles I reference at the end of this post speaks to that point (although it is focused on shotguns, the principles should be the same). That article seems to have some science behind it, which seems rare for the topic of recoil. I haven’t tested it myself, but that would be an interesting experiment … 😉

I may have to try it at some point, but for now I can tell you that I have read several things that agree with what you’re saying. I appreciate the though-provoking comments!

Thanks,

Cal

Great post again but I have one concern that might affect reading. The rifle is resting on sand bags & since ever rifle has different size of stock, maybe different features in the stock which would equal to friction.

Might be a good idea to make a Gun vise with linar guide ways to allow the rifle to move freely in one axis.

Just a thought.

Great points, Naser. I think this paragraph speaks to those concerns:

Remember, I’m not trying to test the recoil among different cartridges. I am trying to quantify the % reduction in recoil with different brakes, and I am testing that on several different calibers. So even if the AI chassis has a different coefficient of friction than the Manners or McMillan stock … I’m not making comparisons between those stocks. I am making comparisons on a single rifle without a brake, and then measuring the % difference with each brake. Then I’m repeating the same exercise with each rifle. That is why it doesn’t really matter what stock each one has, or really how much they weigh relative to the other rifles … as long as the setup is identical for the bare muzzle and each muzzle brake for a particular cartridge … then I’ll be able to quantify the % reduction in recoil for that particular setup. Each rifle is really it’s own controlled experiment.

As I’m struggling to find the right words to explain this, I realize it is probably hard to understand. I think when I start publishing the results you’ll see what I’m saying. Hopefully my ramblings help some! If not, stay tuned and let me know what you think after the next couple posts.

Thanks,

Cal

Great work!!

I am a shooter, an engineer and a teacher and have three comments to your post from each perspective: WOW! !WOW and !WOW!

The way you explained , succintly and clearly the “the whys” and “hows” of a difficult topic should be considered a classic example of the KISS principle ( Keep It Simple Stupid ).

Great great job!!. Keep your posts coming

Thanks, Horacio! I’d be embarrassed if people knew how much time I spent on this post, but it sounds like I accomplished my goal. This is a technical topic with a lot of misconceptions around it, so I was hoping to all get on the same page to help everyone have a better understanding of the results. I appreciate the kind words.

Thanks,

Cal

Decades ago I went through this recoil dilemma on shotguns shooting Int’l or Bunker Trap, where you are allowed a follow-up second barrel. It also applied to American Trap Doubles. Then I applied what I learned on my Big Game and Safari rifles .

That was as a young man, invisible and invisible and what I learned did indeed lessen “Perceived” or “Felt” recoil, but at a price. On the one end you lessen or prevent eyebrow crescents, flinching and detached retinas but on the other you destroy one of the hunter, mil, LE’s very necessary attributes..his hearing. Granted in your PRS you can “theoretically” utilize plugs & muffs [ each LITTLE exception to protection will ring in your tinnitus ears forever ] but in the tall grass or on patrol… muzzle brakes hurt !

I am betting if you had this wonderful equipment and protocol back when you evaluated suppressors..you would have been more willing to put up with their bulkiness.

When your remaining hair gets gray and you are leaning forward to discern just what she said, my comment will not seem so far off topic.

By the Brazos

I hear you! (Pun intended.) This past hunting season, my rifle had a suppressor on it the whole time. In those situations, you never know when you’ll need to take a shot, and you often won’t have time to make sure your ear protection is in place. A couple years ago, I shot two monster hogs while hunting … and I had a muzzle brake on the rifle and no hearing protection. My ears rang for days, and I could tell I had some permanent hearing loss from that … and you can never get that back.

But, I don’t think using a muzzle brake is a sign of immaturity or lack of concern for your hearing. Muzzle brakes are more maneuverable, and (spoiler alert) I’ve found them to be measurably better at reducing recoil than suppressors. That totally makes sense if you think about the constraints of the two designs, but I won’t get into that right now (but probably will before the end of this series). So if having a rifle that is lighter and more maneuverable gives me an advantage in a competition (depends on the format, terrain, obstacles, etc), and knowing that it also will also be better at reducing recoil (which I know makes me personally a better shooter), and it helps me stay on target better … I’m going to cash in on those things. I will double-up on my hearing protection, which really isn’t that inconvenient. I wear those Surefire in-ear plugs, and a pair of amplified ear muffs. You can hear, and that is plenty of protection to prevent any kind of hearing loss from even the loudest muzzle brake.

Hearing loss is a serious issue to me. And when I’m just lining up with some friends at the range and shooting, I always have my suppressor screwed on. Nobody wants to sit next to a brake all day. In the UK, I’ve heard it’s considered rude to not use a suppressor … and I agree with that etiquette. But, in competitions … you better bring your muffs, because if I think a muzzle brake will increase my odds by 1% … that’s what I’ll be running. And I think there is a pretty convincing case that it does, at least for the types of competitions I’m in.

A couple years ago, I couldn’t understand why most of the top shooters in the Precision Rifle Series were running muzzle brakes and not suppressors (see the data) … but I get it now. It isn’t because they don’t have them. They all have them. They all have super-expensive, A+ suppressors. You can see those same top shooters using them at the Quiet Riot match (requires suppressors, see a really cool photo gallery from that match). But, when it comes down to it … they don’t run suppressors when they aren’t required to, because a muzzle brake seems to give you a slight advantage.

Something to think about!

Cal

jeremy kahn July 2, 2015 at 2:08 pm

…”Common knowledge should tell us that a brake does absolutely NOTHING until the bullet exits the muzzle”

…………………………..

Jeremy, Your “common knowledge” is at variance to what I have been told and what I see in super fast exposure film..namely, very high pressure gases bypass the bullet down the barrel…

[ that is why we can protect the bore from dirt/rain/sleet/etc. with tape over the muzzle and said gases have sufficient power to blow the tape out of the way before the bullet arrives ]…

and gas is what a muzzle brake operates on so..the recoil impulse transmitted to the rifle is being elongated BEFORE the bullet exits..sir.

CR is right. 1) There is a column of gas in the bore of the barrel that the bullet essentially has to push out of the way as it makes it’s way to the muzzle. 2) There is also gas blowby, which is essentially propellant gases leaking around the bullet and passing it in the bore. David Tubb talks about gas blowby in his book (read excerpt here), and he gives a theory on how polygonal rifling can reduce gas blowby. And like CR mentioned, this has also been documented and confirmed with recent advances in high-speed photography. Here is an academic reference to this phenomena: High-Pressure Shock Compression of Solids VIII: The Science and Technology of High-Velocity Impact (page 285).

I can’t speak to how much that gas pressure before the bullet exits the muzzle contributes to the work a brake does, but just wanted to confirm that CR knows what he’s talking about. It’s at least worth thinking about. This whole thing is one giant experiment in muzzle brake design, so it’s worth mentioning.

Thanks,

Cal

Lol, You got me, I Should have said “virtually” instead of “absolutely”. The column of air in a 30″ .308 palma barrel is 1.9587571 cubic inches, and weighs .6242gns and add to that the 1-2 gns of blowby (which is probably generous because the “1-2 gns of additional powder to achieve the same velocity” is of unknown correlation due to the fact that it could also be attributed to increased frictional losses in the polygonal barrel requiring more powder, but would need corresponding pressure graphs between rifled and poly barrels for similar loads). Either way , 2.6242gns traveling at roughly 1.5x the bullet velocity(due to the much lower temperature of the barrel air, and the expansional cooling of the leaked gases) the amount of kinetic energy(38.05j) available to work against the brake relative to the recoil forces is miniscule to say the least, especially compared to the 40+gn of gases traveling 3+ times faster than the bullet, once the bullet gets out of the way.

You mentioned or quoted in your article that “muzzle brake science is in its infancy” or something to that effect, and for many in the industry, that may be true. But, for the past 4+ years, muzzle brakes was ALL I did, And I’ve been saying the same thing for all that time, “most people in the industry don’t grasp the science behind it”, That’s not to detract from them, it’s because they “have bigger fish to fry”. It would be hard for a company to justify a 40+ hour a week engineer to do nothing but muzzle brakes, but that is what I’ve done for the past several years.

The only reason I even commented in the first place was because within an hour of the article being posted, I received no less than 2 dozen calls and emails from customers because your statements about the lack of science driven design in brakes mirrored statements that I’ve made in relation to the industry.

There are some pretty smart cookies around here and hopefully we can all learn from one another. I figured you may appreciate my input because there is a true lack of experts in the field of brakes and recoil mitigation, and though you may not have heard of me or my expertise in the field, many of your readers have and suggested I chime in.

Sincerely,

Jeremy

Yes, sir. It was actually Dr. Donald Carlucci who said “Research in this field is still in its infancy…” in a excellent textbook he wrote. And that is definitely the truth. Through this process, I’ve been fortunate to meet a handful of sharp guys trying to apply science to this. But, you’re right … there aren’t many. I’m hoping this series of posts helps change that, and encourages more of a data-driven approach to muzzle brake design. It’s good to hear you were already well on your way in that direction.

Thanks for your input!

Cal

Cal, Thank you for taking the time and resources to do all of these tests. You have the mind of an engineer but as a fellow shooter, can speak to the layman. Whether the reader is a pro or a novice, they can each come away from the readings wiser and smarter on the given subject. Your tests have become some of my go to places when I want to reference things without internet smarts or opinions coming into the equation. Keep up the great work, it has great value to all shooters. I can’t wait to read the rest of this report and any future reports on new subjects.

Thanks, Mark. That’s what I’m going for! So that means a lot.

Thanks,

Cal

This is easily the best article I have seen on all of the sensitivities and inputs on rifle recoil. Excellent work lad!

Thanks, Tom! You aren’t the Tom Hayes who wrote “The Modern Hunting Rifle”, are you?

This new series is looking fantastic, Cal! Looking forward to seeing your results.

Thanks, I’m actually hoping to publish the first set of recoil results tonight!

Thanks,

Cal

A great artical.

So much your time and effort.

You did well all the stages good sight, pulled the trigger, and now is the time to look back results.

Thanks for sharing.

Cal, I’m hoping you can shed some light on a peculiar “sensor” apparatus I have on one of my rifles. It is integrated into a custom wood stock for a Model 52 Winchester. It is centrally located on the left side of the butt. It is a small (6mm diameter), cup-shaped metal apparatus with a threaded 2mm hole in the center. Around the edges of the cup are three equally spaced 1 mm metal discs. It is imbedded about 4 mm into the wood and has a small cavity behind it. The gun was used in small-bore competition by a serious shooter who has now passed away. I was told that the apparatus in question was in some way used to measure lock time and ignition consistency, but I have no other information about it. Have you encountered anything like this? If so, what type of equipment might have been attached to the sensor? Thanks for your time.

Dave

Wow, Dave. I have no idea. There are all kinds of sensors out there, so I’m not sure what would match that description. That definitely has me thinking though! David Tubb is a big proponent of fast lock times, and in Rifle Accuracy Facts (GREAT BOOK!!!), Harold Vaughn touches on the importance of that subject as well. The only thing I can think of is it is some type of sound/pressure sensor that allowed him to identify when the trigger broke, when the firing pin fell, and when ignition started. If they had a high resolution Data Acquisition Unit (DAQ), they’d be able to see the peaks of those two events … and you could infer lock time and ignition consistency.

Thanks,

Cal

This article rocks! I have contemplated the physics of recoil, but lacked the resources for testing the theory.

I would like to add some points to this article.

The law of conservation of momentum you describe can be restated:

Rifle momentum = Bullet momentum + Propellant Gas momentum

If we take the Bullet and Gas velocities to be positive values, the rifle velocity is therefore negative, and summing all three yields zero.

So, let m1 = mass of rifle, m2 = mass of bullet and m3 = mass of propellant

just before the moment that the bullet exits the muzzle, the velocities of the 3 components are:

rifle velocity = v1, bullet velocity = v2, gas velocity = v3

the total momentum in the firing system is:

m1v1 = m2v2 + m3v3

in a locked breech system, v3 = v2/2

that is: the gas center of mass moves at half the speed of the bullet (until the bullet exits the barrel)

Reducing, we have:

m1v1 = (m2 + m3/2)v2

ex. m2 is a 140gr bullet propelled by 70gr of powder

140 + 70/2 = 175gr effective mass traveling down the barrel.

If the bullet exits at 3000f/s the total energy of the bullet and the gas is:

175/7000/32/2*3000^2 = 3515.625 ft-lbs of energy

the bullet alone is:

140/7000/32/2*3000^2 = 2812.5 ft-lbs

gas energy is the difference = 703.125 ft-lbs (a very substantial number)

the rifle recoil energy is the reciprocal of the ratio of the mass of the rifle to the Bullet-gas.

A 7lb rifle’s energy would be 175/49000 * 3515.625 = 12.555

if the rifle was half the weight, the energy would double. lighter rifles in the same caliber kick more

So, that is just to the point the bullet exits. in the articles recoil signature curves, there is the initial rise in force as the bullet accelerates down the barrel, then it reaches a peak and begins to drop. then there is a second rise in the force. this is due to the gasses accelerating after the bullet has exited the barrel. as you can see by your data, there is a substantial increase in the force measurement.

So to restate, the recoil force felt by the shooter has two components:

1. Acceleration of the Bullet+gas to the point of the bullet exiting the muzzle

2. Acceleration due to the increase velocity of the gas once the bullet clears the muzzle

Muzzle brakes serve to change the velocity of the gas (moving at zero degrees to the bullet path) to a direction 270-90 degrees of the bullet path ( velocity is speed and direction combined). this ideally reduces the 2nd recoil component to zero (don’t we wish). in actual practice, some of the gas has a vector component in the bullet direction.

I believe it was stated, that the effect is more pronounced when the ratio of propellant to bullet mass is high. the example above was for a 7mm Magnum. the effect would be markedly different in a shotgun, where the propellant to shot load ration is much lower. the effects of that recoil are primarily the mass of the shot load. hence the ineffectiveness of muzzle brakes on shotguns due to the low mass of propellant.

Testing methods,

the scientific data you present is valid. the physics does not lie. but please consider, no shooter would rest his back against a wall, shoulder a rifle, and fire it. the shooter is part of the system of shooting. the shooters upper torso mass is thrust back upon the firing of a rifle. so the weight of the shooter has something to do with how we perceive the recoil. a young child of half the mans weight would most certainly perceive recoil in a very different sense.

the commenters make some good points that you acknowledge. I got a muzzle brake for my 7mmMag before i ever shot it.

Given the research you have conducted, i believe that a standard(s) for recoil could be specified. after all, recoil is an impulse curve. there could be more than one impulse curve, RI1, RI2, RI3… the gun industry (publications and authors) could measure or assess against these standard type impulse curves.

For any future testing, you could set up the test for free recoil of the system, but add mass to the rifle. use an accelerometer to measure the impulse. the additional mass would simulate the weight of the shooter torso, and the effect of the recoil could be charted based on the size of the shooter. if the area under the curve can be measure, it could be a useful gauge of recoil.

I look forward to your articles in the future.

Wow! Thank you for the thoughtful feedback. I think you’re spot on. I tried to keep from getting too deep in the weeds on this article (and I’m sure many think I was still over-the-top technical), but you obviously have an in-depth knowledge of physics.

I definitely considered some of the approaches you mentioned to simulate a shooter’s body mass behind the rifle. Ultimately, I felt like this setup better represented the forces on the shooter than free recoil. That’s why so many others have used this same approach (like the other studies I mentioned and setups I showed). But, I have seen a government project that has a really advanced setup that mimics the human body structure and resistance with hydraulics. They do sell the same setup commercially, but it was $100k. I personally paid for all this setup out of pocket, just because I was curious and thought it might provide some helpful results for shooters and manufacturers. So I was on a shoestring budget. I do hope people take this project and improve upon it in the future. I definitely see room for improvement if someone was willing to invest the time and money to make it better … I’m just not sure I’d be interested in doing that.

Thanks again for the thoughtful feedback.

Thanks,

Cal

Objective-Subjective Relevance:

> powder burn rate / primer ignition pattern / case shoulder angle / powder column-volume vs. bore diameter / bullet jacket hardness & core composition i.e. obturation force required / presence or lack of pressure rings in bullet design / throat leade angle / rifling contour & number of grooves …these have to have an objective impact on recoil pulse total force under the curve and peak force.

> But what about; LOP / rifle recoil pad surface area & thickness & composition / kickout of toe of recoil pad / stock comb height and shape i.e. Monte Carlo or not cheekpiece or not / drop at nose of comb vs heel / stock cast off / pitch angle of recoil pad & ergonomic contour to shoulder pocket shape / vertical angle of pistol grip & presence – size of palm swell / mercury recoil tubes in either forearm or buttstock or both to lengthen time of recoil impulse…these have to have a subjective impact on perceived recoil that experienced shooters are cognizant of.

There are many ways to ameliorate the perceived “kick” from our weapons.

Yep. All of those things were held constant for these trials, so the muzzle device was the only variable. That was the focus of this study, but there are certainly other ways to mitigate perceived recoil. I saw Bryan Litz’s F-Class rifle last week, and it had a recoil mitigation device built into the butt-plate that essentially spreads the force over more time and therefore reduces perceived recoil. There are a million ways to come at it, but I was focused on how much does the muzzle brake affect it. I feel like this study did a great job quantifying that.

Thanks,

Cal

I hope my comment did not sound to be critical nor dismissive of a well constructed and administered objective analysis of probably the most effective recoil mitigation tool available to us.

My purpose was that of a solicitation of your and your PRB readership’s “tricks” to reduce perceived recoil i.e. a linkage to another line of thought on the same topic…recoil.

My own Blaser Synthetic buttstock has a Hogue piston system plus a Kick-Ez pad installed.