“In the past 4-5 years we’ve made quantum leaps when it comes to predicting bullet trajectories.” –Dave Emary, Ballistician

Ever wonder why you center punch targets at some distances, but your dope is a couple clicks off at other distances? Maybe your shots are dead on at 600 yards but off at 1000 yards, or vice versa. In those scenarios we often blame the rifle, scope, ammo, or ourselves, but is our firing solution as accurate as it should be? This article gives practical insight into some important nuances of predicting bullet trajectory, and shows what drag models the top precision rifle shooters in the country are using to get consistent first round hits at long range.

While it can be hard to recognize, we’re right in the middle of a huge leap forward when it comes to accurately predicting bullet trajectory. I was discussing this with veteran ballistician David Emary recently, and he thought there may have been more advancements in ballistics in the past 5 years than the previous 75 years! What an exciting time to be involved in long range shooting! Honestly, I’ve been wanting to write on this topic for a while to shine a spotlight on what some researchers and industry insiders are saying could be the biggest impact in modern ballistics. I want to help put all this into context, and present what the advances are in plain English along with what they mean to the shooter.

A Brief History of Predicting Trajectory & “Standard” Bullets

To understand where we are and where we’re headed, we must know where we’ve been … but I promise this is relevant and I’ll keep it brief!

In the 1740’s, a ballistician discovered the drag force on a bullet could be over 100 times more powerful than the force of gravity, and that amount of drag force varied based on the bullet’s velocity. That event triggered 200+ years of research. Progress was slow because aerodynamic drag is a very complex process, and the calculus required to compute a single trajectory was lengthy, tedious, and done by hand. An early observation was the drag force was different for every type of bullet – the drag a bullet experiences in flight is unique based on its shape. However, the thought of somehow trying to measure and compute the drag for each and every type of bullet over the full velocity range from the muzzle to the target seemed impossible!

Around 1850, Francis Bashforth proposed a practical solution to simplify things: What if we established a “standard” bullet, and did all the comprehensive drag measurements and complex calculations for that one “standard” bullet? Then we could take the results for that “standard” bullet and make it a model that we simply scale somehow for other bullets to avoid the hassle of performing exhaustive measurements and calculations for hundreds of bullets. That brilliant idea was a catalyst for a new era in applied ballistics, and is the foundation of what we’ve used to this day.

From 1865-1880, live fire tests were conducted by practically every major military and reported in extensive ballistics tables. Shortcut equations were developed from those results to calculate trajectories more quickly, and they learned how to scale the known drag of a standard bullet to compute the trajectory of other bullets using something called a “Ballistic Coefficient.” This worldwide effort eventually culminated in standard drag models for a few shapes and sizes of bullets, with the G1 standard becoming the most popular.

A Ballistic Coefficient (BC) is a number used to describe the drag on a bullet compared to some standard bullet. For example, a G1 BC is comparing the drag of that specific bullet to the G1 standard bullet. The higher the BC, the better the bullet will be able to retain its velocity downrange and be less affected by the wind.

Shooters in the civilian world have been using G1 BC’s to calculate trajectories since Winchester and Sierra Bullets started publishing ballistics tables and data in the 1960’s and 70’s. An accurate BC is the foundation of a reliable firing solution. “Ballistic coefficients of bullets are important because under or over estimates of ballistic coefficients can dramatically impact predictions of long range trajectory, wind drift, and impact energy,” explains Michael Courtney, in research published by the US military.

However, it was noticed that the BC for bullets vary at different velocities, and sometimes that change could be significant. To provide a more accurate solution for the problem of velocity-dependent BC’s, Sierra Bullets started publishing multiple BC’s for each bullet that are broken up into several velocity “bands.” Here is an example:

One problem with the multiple BC approach is that most ballistic calculators don’t allow you to enter multiple BC’s, although there are a few with that feature (like the Shooter phone app). Another solution is to use the average BC over the velocities you’ll be shooting, but that means the trajectory may not be accurate over the entire range (i.e. your solution might be on at 600 yards and off at 1000 yards, or vice versa).

G7: A Better Standard For Long Range Bullets

In the late 2000’s, ballistician Bryan Litz proposed the G7 BC is a better standard for modern long range bullets. Others in the academic and research world also made that observation and saw it as a simple fact, but that idea challenged the popular opinion and established practices of the shooting community. “The reason why the BC of a modern long range bullet changes so much at different velocities is because modern bullets are so different in shape compared to the G1 standard that it’s BC is based on. In other words, the drag of a modern long range bullet changes differently than the G1 standard projectile, so the coefficient relating the two (the ballistic coefficient) has to change with velocity,” explains Bryan. Basically, if you don’t choose the standard that most closely matches your bullet the result will be velocity dependence and associated problems with BC’s. The standard that bears the closest resemblance to most modern long range bullets is the G7 standard.

A good rule of thumb is if you are using a short, flat-based bullet, go with the G1 BC. If you are using a long bullet with a boat-tail and pointy nose (like most modern long range bullets), then the G7 BC is likely a better fit. As a result, using a G7 BC should be more constant and reliable for all velocities and ranges. Bryan summarizes it this way: “A trajectory that’s calculated with a G7 BC doesn’t suffer as much from the same velocity dependence problems and inaccuracies as calculations that are made with a G1 BC.”

The excerpt below is from Ballistic Performance of Rifle Bullets (3rd Edition) by Bryan Litz and it is based on BC’s carefully measured through live-fire experiments. The book has data like this for hundreds of bullets, but I picked the DTAC 6mm 115gr RBT bullet as an example, because it is extremely popular in the PRS. The page includes a chart that shows how the G1 and G7 BC change based on the velocity of the bullet, and it also quantifies the variance of each type of BC over supersonic flight.

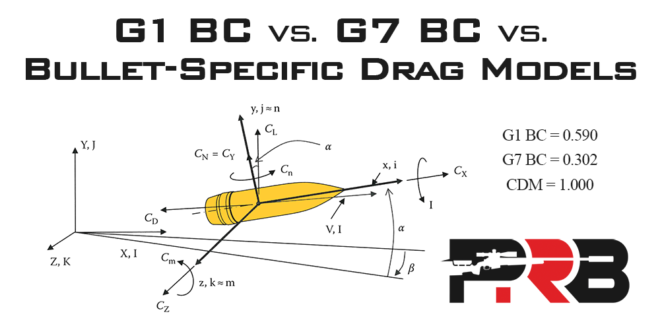

Clearly the G7 BC is a better fit for this bullet, and 99% of the other bullets covered in the book. In this example, the G1 BC varies from 0.657 at high velocities down to 0.535 below 1500 fps. That’s a variation of 20%! There is a significant slope to the G1 BC line on the chart, and you can see the line trail off significantly as the bullet slows. If you were using a G1 BC, what number do you put in your ballistic calculator? The average is 0.590, but you know that isn’t going to produce accurate results at all ranges – meaning you may be on at 600 yards but off at 1,000 yards, or vice versa. On the other hand the G7 BC only varies from 0.311 at the highest velocities down to 0.300 below 1500 fps, which is less than a 4% variance. In this case, if you enter the average of 0.302 G7 BC in your ballistic calculator it is going to be very close at all ranges.

Note: If you noticed the G1 BC is a higher number than the G7 BC, don’t be distracted by that – it doesn’t mean anything to the shooter. The number for a bullet’s G7 BC will typically be about half the number for its G1 BC for the same bullet, but just because the G1 BC is higher doesn’t make the bullet fly any different! Just be sure to select the correct drag model in your ballistic calculator for the number you entered.

The example above is typical – I didn’t cherry-pick a bullet that exaggerates the point. Honestly, that is just a bullet I’ve used a lot. Other independent research has measured similar variance, saying things like, “As expected, the G7 BC shows much less change with different velocities than the G1 BC for boat tail bullets.” (Courtney). I will point out that bullets designed for Extreme Long Range in big bores like the 375 CheyTac, 416 Barrett, or 50 BMG can have twice as much variance in the G1 BC over their velocities as what is shown in this example.

Does that mean you can’t use a G1 BC to hit targets? Nope. I’ve seen exceptional shooters who I highly respect use G1 BC’s to achieve first round hits out to 2 miles! They may just have to do more truing/calibration. Are G7 BC’s always better? Not exactly, but they do usually vary less with velocity, meaning once you find the right number for a G7 it is more likely to align with hits at all ranges than a single G1 BC. G7 BC’s are still an approximation based on a standard bullet, so there will still be slight variance from the actual drag – but it should be a much better fit than G1 BC’s for most long range bullets and therefore require less truing/calibration.

Can I Trust The BC Printed On The Box?

As long range shooters, we love high BC bullets. It’s powerful to have a single number that represents how aerodynamic a bullet is. BC is seen as a performance measure, similar to horsepower in a car – the higher the number the better! So, manufacturers know it’s in their best interest to publish the highest possible number they could justify. That may sound cynical, but BC is very interpretive. In the example above, Sierra provided 4 different BC’s for various velocity bands, so if they just advertise one number which do they pick? That’s right, the highest one! While it might be more helpful for long range shooters to publish the average BC over a wider range of velocities, that’s not what happens. And it’s not just Sierra – practically everyone does it. “The majority of industry published BC’s is measured over relatively short ranges of 100 to 300 yards, which corresponds to velocities around 2500 fps depending on muzzle velocities,” explains Hornady.

Think about it: If everyone else is publishing best-case-scenario BC’s based on high velocities, you might as well play along or you’re handicapping yourself. Of course, a few companies seem to be more “optimistic” in their published BC’s, with independent research showing some manufacturers overestimate BC’s by more than 10% (Courtney) – so I’ve learned to be highly skeptical of the BC from most manufacturers.

Another problem is many manufacturers only publish G1 BC’s, and not G7 BC’s. So if we don’t have accurate G7 BC’s for our bullets, changing to that as the standard is just a good idea with no way to implement.

That brings us back to Bryan Litz. Several years ago, Bryan saw that the lack of accurate BC’s for bullets was becoming a limiting factor. So he started conducting live-fire tests to independently measure the real-world BC of popular rifle bullets to help the long range shooting community create more accurate firing solutions. His experiments were carefully instrumented so the resulting BC’s were accurate to +/- 1%, and Bryan has been publishing the results of that ongoing research for several years. This was a huge service to the shooting community, because now you can just look up the “Litz BC” and have a high degree of trust that it is accurate. Bryan has compiled a library of G1 and G7 BC’s measured from his live-fire testing and there are several ways to find those numbers, but if you want the entire list you should just buy his bullet library book that contains comprehensive info for 720 bullets (see the full bullet list).

A Quick Summary Of Where We Are Today

Today, shooters have powerful tools and data available which allow us to predict bullet trajectory at a whole different level of accuracy. New chronographs, like the LabRadar and MagnetoSpeed, have been released that provide very accurate muzzle velocities and avoid common pitfalls/errors associated with traditional, light-based chronographs. Then we have access to accurate G7 BC’s measured from Litz’s independent live-fire tests. Finally, handheld weather stations like the Kestrel Weather Meter allow us to gather on-site atmospherics in real-time. That is important because the drag a bullet experiences in flight changes based on the density of the air, so being able to measure the exact conditions allows us to customize the firing solution to be even more accurate!

All of those things have increased the quality of our inputs into a ballistic engine and therefore increase the quality of the output. If you combine all those things with a good ballistic engine, the output should very closely match your impacts in the field at most ranges without the need for much truing or calibration.

New Bullet-Specific Drag Models

Over the past decade, equipment and shooters have become much more capable, and started stretching out to distances that would have seemed ludicrous 10 years ago. That’s when we ran into a new problem. Bryan explains that “small differences in shape between a given bullet and the G7 standard can lead to significant misrepresentations of drag for that bullet at transonic speeds.” Transonic speed is when the bullet has slowed down to around 1300 fps, which is typically a long way out there, but the exact distance depends on the cartridge, bullet, and atmospheric conditions. For context, that might roughly equate to a distance around 1100-1200 yards for a 6.5 Creedmoor or 1500-1600 yards for a 338 Lapua Mag. We could use a good G7 BC with an accurate muzzle velocity to predict trajectory and get reliable first-round hits through supersonic flight, but as we stretched beyond to extreme distances the bullet became unpredictable again. It turns out that a specific bullet’s behavior at transonic speeds is unique, like a fingerprint. G1 or G7 standards are basically generic fingerprints – they won’t ever be a perfect match for a particular bullet, and that becomes especially apparent at transonic speeds.

That brings me to recent, very-exciting developments around drag modeling. In the opening, I mentioned back in the 1700’s and 1800’s “the thought of somehow trying to measure and compute the drag for each and every type of bullet over the full velocity range from the muzzle to the target seemed impossible!” That’s what led us to using standard drag models like the G1 and G7, which are simpler to apply and didn’t require modeling the actual unique bullet drag for each and every bullet shape. In most cases, the drag shapes are similar enough that simply scaling the drag curve in trajectory predictions was accurate enough. However, today we have equipment that makes measuring drag over the full flight easier, and computers are able to do the real calculus-based math much faster than mathematicians doing it by hand. While we’ve been using G standards to model drag for 100+ years, we have entered a new era!

Lapua, Applied Ballistics, Hornady, Barnes Bullets, government research labs, and others have recently started using Doppler radar to record extremely precise bullet trajectories. These aren’t LabRadar’s, but professional grade, $100,000 Doppler radar systems like the Infinition BR-1001. Doppler radar can record the exact flight of the bullet all the way down range, resulting in thousands of data points with an accuracy that is within a few millimeters! Barnes Bullets says their “Doppler radar system can track bullets out to 1500 meters, recording the velocity and time of flight of that bullet every few feet along the flight path.” These companies then analyze that data to define the specific drag of an individual bullet at a whole new level.

“These continuous air drag coefficients make it possible to calculate the trajectory of your bullet much more accurately than using the simplified one-number B.C.,” explains Lapua. We no longer have to compare a bullet to a generic standard, but we have the precise and exact drag of that particular bullet.

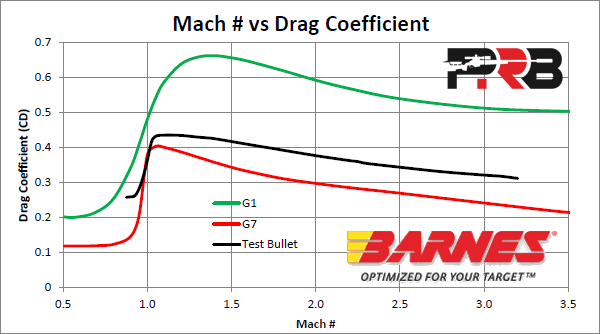

The chart below compares the bullet-specific drag curve from research conducted by Barnes Bullets with their Doppler radar to the G1 and G7 drag curves. Note: If you’ve never seen a drag curve chart like this, here is a good explanation on how to read them and what they mean to the shooter.

It’s clear the drag curve based on the actual readings from the Doppler radar above doesn’t exactly match the shape of the G1 or the G7 curve. It is most similar to the G7 (no surprise), but it doesn’t match it perfectly. That’s because the drag curve of every bullet is unique, like a fingerprint. The drag would only perfectly match the G7 standard if the bullet was a perfect match physically to the G7 standard bullet, and that is virtually never the case.

The chart below is from Applied Ballistics research, and shows how the measured drag of another specific bullet doesn’t perfectly match the scaled version of the G1 or G7 curves for that bullet. On the right side of the chart, you can see the actual measured drag closely matches the G1 and G7 drag models, so at short to mid-range the G1 BC would give fairly accurate results. But as you move to the left of the chart and the bullet slows down the models diverge. Again, the actual drag more closely matches the G7 curve, but isn’t an exact match.

Below is a similar chart from Hornady’s research that shows how the measured drag of a few different bullets compare to the G7 standard drag. While they are similar to the G7 drag curve, each bullet has dynamic behaviors that are unique in some way.

The Applied Ballistics team refers to their bullet-specific drag models derived from live-fire testing as Custom Drag Models (CDM). Applied Ballistics was the first to pioneer bullet-specific drag models, even before the use of Doppler radar. I asked Bryan Litz about this recently, and he said, “Before we got radar, we would measure several points of drag along the curve and connect the dots. That worked very well, but Doppler radar provides a continuous measurement. We are in the process of going back through the library and updating all bullet models with radar measurements as well as the latest versions (lots) of those bullets.” The Applied Ballistics team has now conducted careful live-fire testing necessary to establish the CDM’s for 815 modern bullets and counting! For more info on how you can start using these CDM’s from Applied Ballistics visit here. (Note: I share my personal experience with the accuracy/reliability of Applied Ballistics CDM’s in this post.)

Hornady is pioneering a similar approach with rich Doppler radar data they’ve recorded, and they’re also moving away from BC’s to bullet-specific drag profiles. They do a great job of articulating their approach:

Why calculate a trajectory using a mathematical comparison of your bullet to a “Standard Projectile” (oversimplification of BC) when you can use an exact model of your projectile in the trajectory calculation (Drag Coefficient)? Using Doppler radar, Hornady ballisticians have calculated the exact drag versus velocity curve for each projectile in the 4DOF Bullet Library. Ballistic Coefficient can change as velocity changes. A drag curve doesn’t change; the curve is specific to each projectile and is directly related to its trajectory. (Read more)

Hornady allows you to use these bullet-specific drag profiles for FREE in the Hornady Ballistics app, which is available on iOS and Android devices. Hornady currently has these 4DOF bullet-specific drag profiles in their library for around 50 Hornady bullets, 8 Berger bullets, 1 Fort Scott bullet, 7 Lapua bullets, 2 Nosler bullets, 13 Sierra bullets, and 6 Warner Tool bullets. So the bullet selection isn’t near as broad as Applied Ballistics data, but Hornady is adding to their library all the time as well. When they were asked why there aren’t more bullets in the Hornady 4DOF database here was their response: “Hornady technicians will continue to add Hornady projectiles and other bullet brands to the database. Testing is time-consuming, but rest assured, there will be more projectiles added to the library.” I can only imagine how time-consuming this is, but thank you guys for pioneering!

Barnes Bullets and Lapua have also shared some of their data. Barnes data can be found on their website, and Lapua has created an app that gives you access to data for their bullets.

At this point, Doppler-based data has only been measured on a limited number of bullets and most manufacturers aren’t publishing their data publically, but instead simply integrate it into their proprietary ballistic solvers. While that is helpful, I agree with a suggestion Dave Emary made in an article he wrote for Guns & Ammo magazine: “I hope the industry begins publishing Cd versus Mach number curves so the advantages of this system can be more readily adopted by everyone.” I realize proprietary data can be seen as a competitive advantage, but that certainly isn’t putting the customer first. For example, Hornady recently partnered with Kestrel to release a new ballistic weather meter that allows you to use their 4DOF bullet library (more on the Hornady Kestrel). So if I want to use the Applied Ballistics drag models, I’d have to buy the Kestrel with the Applied Ballistics engine, but if I want to use Hornady’s drag models I’d have to buy a different device. While that may be good for the profitability of those companies, it’s not in the shooter’s best interest. Often when multiple businesses in an industry don’t put the customer first, it is a preamble to disruption. Think about it: Netflix didn’t kill Blockbuster – ridiculous late fees did. Uber didn’t kill the taxi business – limited access and fare control did. Apple didn’t kill the music industry – being forced to buy full-length albums did. A more collaborative approach where researchers share their findings publically would allow us to learn from each other and help move the shooting industry forward more quickly. I recognize there has to be a way to monetize all the R&D going into this for it to be sustainable, but what if we could use one device and had the option to pay $5 for whatever drag profile we wanted instead of being forced to commit to one camp or the other? It doesn’t have to be an either/or decision. There is a way that open-handed collaboration could benefit everyone.

So What Are The Top Precision Rifle Shooters Using?

While all this advancement is clearly exciting to me as an engineer, I’ve actually heard some respected shooters say they still thought G7 BC’s were more accurate. One of the guys who told me that was a top shooter in the PRS and a guy I highly respect, so it wasn’t just some random guy at the range! That’s what made me think it’d be interesting to ask the top precision rifle shooters in the country what drag model they were using. The survey was based on 170 shooters that finished highest overall last season in the Precision Rifle Series and National Rifle League. I asked what ballistic engine they were using, and if the shooter said they used the Applied Ballistics engine I knew that engine allows them to choose from a G1, G7, or Custom Drag Model, so I asked a follow-up question to those shooters to see which they used most often. Here is what they said:

The various colors on the chart represent the league and rank of the shooters. For example, black indicates shooters who finished in the top 10 in the PRS, dark blue is those who finished 11-25 in the PRS, and the lighter the blue, the further out they finished in PRS Open Division season standings. The green colors represents the top shooters in the NRL, where the darkest green is the top 10, medium green is 11-25, and light green are 26th to 50th. The legend on the chart itemizes the league and ranks each color represents, but basically the darker the color, the higher up the shooters placed.

So of the 130 top precision rifle shooters who said they were using the Applied Ballistics engine, 63% said they use G7 BC’s to calculate their ballistics, 27% used one of the Applied Ballistics Custom Drag Models, and finally just 10% use G1 BC’s.

This could be my own personal bias playing in, but I can’t help but wonder if we’ll see that trend change over time to see more people opting towards bullet-specific drag models. In the past, it has been fairly complicated to load these custom drag models onto your device, and sometimes you have to pay extra for them, so that extra hassle/expense might be limiting how many have made the switch and not necessarily because they don’t believe they’re accurate. I will say that loading one of Applied Ballistics CDM’s onto a Kestrel has become much easier lately through the Kestrel LiNK Ballistics phone app. I’d also bet there are people who may not have heard of bullet-specific drag models or understand how they’re different – which is why I’m writing this post! 😉

I was talking about these results with Dave Emary, a respected ballistician, and he wasn’t that surprised by these results. He pointed out that most PRS-style rifle matches don’t have targets beyond 1200 yards, and BC-based firing solutions are adequate for those distances. It’s really only when you stretch out beyond 1200-1400 yards that a bullet has slowed to the point that the nuances of a specific bullet’s drag will start to result in misses, and that’s where bullet-specific drag models become really valuable for first-round hits without the need for extensive truing/calibration. Dave also explained that one of the big goals behind bullet-specific drag models and some other recent work with the military is to provide a way for a guy to jump out of a helicopter anywhere in the world, input the current atmospherics into a ballistic solver, and then be able to connect first-round hits on man-size targets beyond 2000 meters without the need to true/calibrate his ballistics for that environment or even re-zero his rifle. And they’re now successfully doing that, thanks to highly accurate, Doppler-based, bullet-specific drag models. Wow!!!

It does seem clear that the whole industry is trending in the direction of Doppler-based, bullet-specific drag models. This article cited research from several different companies, along with respected researchers and ballisticians. We all recognize the merit this new approach has, and are excited about the new possibilities this will open up as more bullets are tested and we’re able to apply these advances in the field. I believe this is literally the most exciting time in history to be a long range shooter, and I hope this helps more shooters recognize the significant shift this represents when it comes to predicting bullet trajectory and connecting first round hits at extreme distances.

In the next post, I’ll go one step further into the rabbit hole by highlighting some of the most interesting research I’ve come across in a while, and I’ll also take a look forward to what could be “The Final Frontier” when it comes to predicting bullet trajectory. Stay tuned!

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

nice , it’s a perfect post ,

thank you for share

Thanks! I spent a RIDICULOUS amount of time writing it (and the next post), because I think it represents the biggest advancement in ballistics of our generation – but so many shooters are slow to warm up to new ideas. We like our tried-and-trued approach. That’s why some still use G1 BC’s for long range, which is basically the ballistic equivalent of flat-earther’s. They just don’t understand the science underneath, so I wanted to carefully lay it out in a way I hope most people could understand … even non-technical people. I hope this helps us all recognize the cool moment in history we’re standing in. It’ll be fun to watch it unfold!

Thanks,

Cal

I liked the article. I wish you wold have mentioned the book Applied Ballistics for Long Range Shooting.

It has the program Applied Ballistics, and a bullet library in the back. Also the Wilcox’s Raptor, S, and M. Talk about advancements in ballistic technology. Now you can have a complete ballistic solution. Wind included.

Most of the time I get my lab Raydar velosity and my G-7 BC then add the other specs. And generate a drop chart that I tape to my sun shade. It’s not as accurate as using my Kestrel with Applied Ballistics because it doesn’t account for current conditions, but its usually within a half minute. Being able to look at the drop chart dile up and shoot is to me more fun than playing with my instermintation. Back in the day we got our velosity from a chronograph and looked up the bullet drop in our Sierra reloading manual. Most of the time it was close. Brian Litz has made the game a lot more rewarding.

Thanks, Kurt. I thought about including some of the things you mentioned, but was afraid the article was already getting too long-winded for a lot of people. We have a short attention span on the internet! 😉 I do whole-heartedly agree that Bryan Litz has had a huge impact and helped us all hit a lot more targets, which is much more fun than the old spray-and-pray method!

Thanks,

Cal

Great article! Could you please do an article on GLASS? What companies make glass for scopes and spotting scopes. What glass is used by what company? ETC?

Thank you

Thanks, Raymond. Your suggestion is a good one. I’ve had a few conversations with industry pros on that topic, and it’s intriguing. I may file that one away and do it one day. I appreciate the suggestion.

Thanks,

Cal

Great article Cal. The bit towards the end about everyone having their own proprietary Kestrel is disturbing for us shooters for sure. Hopefully they will all realize that this is not helpful for the customers. Truck manufacturers have their own special details, but you can still buy one brand of gas to run a Ford or a Chevy. For those of us that love our Kestrels, we consider it the gas!! Leave it alone.

Glad you enjoyed it, Dale. I agree. Where we end up without collaboration might not be good. I will say that the Hornady Kestrel is priced at $500, which is $100 less than the Applied Ballistics version, which is a nice thing … but it also has some limitations like only being able to load 3 gun profiles (the Kestrel 5700 Elite is $700, but allows 30 profiles). It also doesn’t have the range card, or multiple target functionality … but lowering the entry price to $500 will help some people be able to get a very capable tool. Ultimately, I hope we don’t head down the road of proprietary data and engines … but I can also sense we may be on the cusp of an arms race when it comes to advanced ballistics engines. It’ll be interesting to see how this plays out!

Thanks,

Cal

Is it even possible to meaningfully distill a CDM down into a number like a G7 BC that allows for quantitative comparisons for the consumer? Setting aside the problem of comparing CD ballistic solutions across different proprietary manufacturer libraries, right now we can at least compare form factors based on standardized G7s. Perhaps the CDMs could be for sale individually but the manufacturers could agree on and publish some sort of standardized number?

Is that even possible? If so what would be the best way to do it? Thank you!

Aono, that’s a great question. The short answer is no, you can’t represent the real drag of a bullet (i.e. the Cd vs Mach chart data) with a single number. BC’s make comparing bullets easier because of that, which is what I had in mind when I wrote “It’s powerful to have a single number that represents how aerodynamic a bullet is. BC is seen as a performance measure, similar to horsepower in a car – the higher the number the better!” Now they could develop a standard by saying they’d publish the drag on the bullet at Mach 2 or something (roughly 2250 fps). My bet is BC’s don’t go away, so we’ll always have them for reference … although we saw how much variance there can be from one manufacturer to another, so it’s not entirely helpful. That was another important aspect of Bryan Litz’s work, in that we had a list of BC’s that were all measured with similar methods accurate to +/- 1% and it made it really easy to compare one bullet to another. It was an apples-to-apples comparison, without being skewed by how “optimistic” one manufacturer was over the other.

Ultimately the real drag models are rich data sets that aren’t easily summarized, but my bet is we continue to have access to BC’s for ease of comparison, even as bullet-specific drag models become more popular.

Thanks,

Cal

As a long range shooter and computer engineer I’ve been a fan of the CD based ballistic computers for a few years now.

I’m really excited about the marriage of radar verified ballistics and AI.

Something as powerful as a. iPhone with a learning based ballistic engine could really take the term “truing” to the next level.

Interesting thoughts, Greg! Watch out, this is a rabbit hole for engineers! I have been consumed by thinking about this at a few points in the past, including the past couple months. It is REALLY interesting stuff, and one of the most exciting things going on in the shooting industry right now. I think we’re about to see a full-blown arms race when it comes to advanced ballistic engines.

Thanks,

Cal

Cal: thanks for all the work you do in putting together this column. always a good read. especially this episode. I am a hunter as opposed to a competitive shooter but accuracy is very important to me.

I want that bullet to go where I want it. To enhance that possibility, I reload. I haven’t bought a commercial cartridge (other than 5.56 for my AR) for many, many years. So, the information provided by the bullet and powder makers has always been very important to us as reloaders. The evolving science of ballistics, gives us information never attainable before. Though that information’s precision may be useful to some and ignored or debated by others, it’s science based, experimentally proven information that moves us all forward in one way or another. A toast to the engineers and scientists!!

Greg, I really appreciate your thoughtful comments and couldn’t agree more! Your response shows that I hit the mark I was going for with this post. This is applicable in a lot of different shooting disciplines, and while it’s ignored or debated by some … “it’s science based, experimentally proven information that moves us all forward.” Thanks for taking the time to share your thoughts.

Thanks,

Cal

Hello Cal,

Thanks for these insights. Resistance to advancements in shooting is historic. Laminated stocks only became more common in the U.S. in the 1960’s. Whereas that’s the way the standard German Mauser was stocked in W.W. 1!

Gene Solyntjes

You are spot on, Gene! Barrel rifling was invented around 1500, but didn’t become commonplace for over 300 years! That was a revolutionary idea that very few recognized when it first appeared. A more modern example was the migration to 416 stainless steel, which is what the majority of match-grade barrels are now made from. In the book Extreme Rifle Accuracy, Mike Ratigan reminds us 416 stainless steel was “another modern technology” many shooters were “slow to warm up to.” It’s understandable that many shooters are hesitant to depart from proven methods, but we should at least be open to new ideas. Those with a fixed mindset that doesn’t even seek to understand new ideas are basically the modern equivalent of flat-earthers, which isn’t going to get us anywhere. I’m not saying we should all be early adopters of every new thing that a company comes out with, but advances like this can represent a paradigm shift. I know there are a ton of shooters who read my content, so hopefully this will make some contribution to help the shooting community be more open to these exciting advancements that are coming out and at least give them a try before they dismiss them as a fad. In reality, I know it will take a lot of time for this to become popular across the shooting community, but maybe this will give it a jumpstart so it will spread among the early majority.

Thanks,

Cal

Another well researched and presented post. Very valuable. My knowledge has increased significantly since finding your site.

Thanks, Mike! I did put a RIDICULOUS amount of time and thought into this post (and Part 2 of this, which I’ll publish next), because I wanted it to be both accurate and easy for non-technical shooters to understand. This is probably the most exciting development in the past few years and maybe of our generation, at least in my eyes. We’ve basically been making incremental improvements since the late 1800’s, until about 2014 … and things started to take what will appear one day in retrospect to be a monumental shift in how we predict trajectory. It’s not an incremental improvement – it’s a paradigm shift! That doesn’t happen every day, so I wanted to try to draw a few more shooter’s attention to it. Exciting times!

Thanks,

Cal

I have a less mature idea, in fact I am doing this “stupid thing.”

I customized a mold to cast bullet and wanted to measure its BC. The tools I have on my hand are only strelok pro and light-based chronograph. can i made it? Is there any advice for me?

thanks

Ha! That’s an interesting question. I’ll offer my thoughts, but I’d invite other readers to chime in if you have any suggestions.

What I’d probably do is measure the velocity (as best you can), and then shoot the bullet at distance and determine the drop. Ideally you’d the distance would be around the spot where it has slowed to 1300 fps, because that’s where the bullet starts to act squirrely (i.e. it has a very unique drag based on it’s shape, as we learned in this article). Then input your muzzle velocity into Strelok Pro (great ballistic app, by the way), and adjust the BC until the output matches the adjustment you had to make to center a hit at whatever distance you were shooting.

I will say that most light-based chronographs aren’t the most reliable measuring devices, so this would be a very rough way to go about it because of that. If you had a LabRadar or MagnetoSpeed, I’d have more confidence in this approach, but ultimately this was the best idea I could think of with the tools you have on-hand, and I bet it gets you in the right ballpark.

Thanks,

Cal

Thanks for the great article and the reply Cal. I’ve been wondering about this question specifically for quite a while, and was happy to have the opportunity to ask the question under a relevant article. I thought your answer to be the case, but lacking direct experience with CDMs I wasn’t sure if I was missing anything. Of course, as you point out this would be much less of an issue for the consumer if the CDMs were not bound to one or the other manufacturer, and comparative simulations were easier to run.

Now, (off topic, but) if you could only solve the mystery of why swaged copper bullets have aerodynamically lagged so far behind their lead or lathe-turned cousins thusfar, I could finally stop counting sheep over that as well. Given Barnes’s and Hornady’s doppler work, and outfits like Warner and Cutting Edge demonstrating that it can be done amazingly well with copper solids, I would think that GMX/LRX wouldn’t be such pigs as they are. I’m very hopeful that Hornady will perhaps A-Tip the GMX lineup and address this, but don’t understand why they haven’t at least already improved the shapes, besides a (perhaps obvious) consumer demand factor. I for one would certainly prefer to spend a little more on a lead-free monolithic hunting projectile that flies like an ELD and is backed up by a CDM. Yet there’s not a single swaged lead-free VLD on the market. Given how critical retaining velocity is for these projectiles to perform correctly, it’s quite disappointing.

Thanks, Aono. Glad you found this content helpful. It easy for marketing material from one company or another make this confusing, but hopefully I presented in a fairly straight-forward and balanced perspective.

Now the second part of your comment is a very loaded question, which would deserve a complete post or two to even get close to answer. While this goes against my better judgement, I’ll try to quickly hit some of the big points, because I’d like to help you out. There is a HUGE debate between solid, lathe-turned bullets and jacketed bullets. It could fill books. But there are pros and cons to both approaches, and I’ve talked to guys who have literally spent years of their lives trying to perfect one or the other. Each of those conversations have been enlightening, but I admit I’m not the expert on this … I’ve simply talked to some, so I’ll share what I can. One of the big benefits of lathe-turned, solid bullets is that you can shape them with a CNC machine with very fine-grained control. You can make them whatever shape you design, with very little limitation (if you have the right equipment and attention to detail). The sky is the limit! With jacketed bullets, you are a little more limited based on the mechanics of your components/dies and the process of how they are physically assembled. However, with jacketed bullets you have fine-grain control on another important aspect of a bullet, which is the distribution of it’s weight. You can basically fine-tune how much weight is in the back of the bullet or in the nose. Further, solid bullets are made from an alloy that isn’t always 100% consistent (even if you pay a lot of money for high-grade material), which means there can be a difference between the “center of mass” and “center of form.” That can cause instability/inconsistency in flight, which means larger groups and the bullet can even tumble catastrophically if it becomes unstable at distance. Jacketed bullets can have that same issue, but you have a little more control over that if you commit to quality components with thorough QA and equipment setup. Honestly, lots of that is addressed through tight controls over consistent bullet jacket thickness (i.e. jacket runout). While I’m sure there is someone out there that would fiercely oppose that view, I believe it’s the truth and to see evidence you simply need to look at what kind of bullets the top Benchrest shooters are using for the tightest groups at both short-range and 1000 yards. The guys winning are ALL using jacketed bullets, because the flight of the bullet is more consistent. Low drag is important to them (because it results in less wind drift), but that doesn’t trump precision. But as you get further out, the advantages offered by lathe-turned solid bullets start to become more compelling, especially when you look at big bore calibers like 375 and larger. The extremely low drag counts for a lot in the Extreme Long Range game, so that’s why you see most of those guys using lathe-turned solid bullets.

I will actually get into the A-Tip a little in the next post, so I’ll avoid that rabbit trail for now. But, I will say every bullet has specific design goals. You mentioned hunting bullets, which have different design goals than target bullets. For a target bullet all of the design is 100% focused on consistent and aerodynamic flight from the muzzle to the target (i.e. external ballistics). They don’t care one bit what happens when the bullet hits the target (i.e. terminal ballistics). In hunting, they care very much about what happens in terminal ballistics, and try to balance that with external ballistics. Any time you are trying to balance two competing design characteristics, you will be forced to make compromises in one direction or the other, and often times people won’t agree with your decisions … as seems to be the case here! 😉

I will say that I used solid bullets for hunting the past, and no longer do that. I’ve had bullets slip through an animal completely without expansion, which was not okay. I personally hunt with either the Berger’s or Hornady ELD-X or even ELD-M bullets at this point, and have taken quite a few amazing animals with both of those. In fact, every animal I’ve ever shot at with those bullets ended up in the back of the truck. I’d highly recommend either of them. Now, I have heard lots of guys say they hunt with solids, but my experience wasn’t good with them. I would bet they work well within certain applications and ranges, but they may require more precise shot placement than those others I’m mentioning. For example, you may need to hit bone (i.e. “give the bullet something to bite on”) to prevent a pin-hole pass-through. The Berger or Hornady bullets typically penetrate 2-3 inches and then have devastating expansion, and are able to do that within a very wide range of velocities. That means at 100 yards or 1000 yards, they’re going to do the job. Now, those bullets may ruin more meat, but they’ve resulted in quick/humane kills in my experience. I’ve never once been disappointed with the terminal performance, and the external ballistics performance is world-class as well. They might not be as aerodynamic as some of the lathe-turned solids, but they are in the same ballpark.

Hope this helpful! Since I’m not an expert in this area, I invite anyone to correct anything I said that you believe might be misleading or short-sighted. As always, I welcome peer-review!

Thanks,

Cal

Cal, great article. My 67 year old father decided he wanted to get into long range shooting about 2 years ago. He picked up a nice savage and a book to get started. He doesn’t pick up on the technical side of things very quickly, so this is going to be a great read for him. I’m passing it along right now.

That’s great, Nathan. He is exactly the kind of guy I was trying to help with this post. I want to make these kinds of things more accessible to shooters. So I appreciate you sharing that.

Thanks,

Cal

Looking at a wide range of bullets, there is a perfect correlation between G1 and G7 results. This is straightforward to see by evaluating the two from any number of publications. So in terms of providing improved ballistic calculations, the different measurements alone do not offer any new information. It is the standard drag curves which the different coefficients reference that offer improvement.

Charlie, I think I understand what you’re saying, but I’m not quite sure. Yes, the different shapes of the drag curves are what separates the G1 and G7, and not that they’re calculated differently or the process for how the drag is applied is different. If that’s what you mean, I agree … but if I’m misunderstanding what you’re saying, please let me know.

Thanks,

Cal

Excellent piece, Cal. As a fellow engineer, I appreciate your technical orientation while still offering approachable prose.

I do find it a bit frustrating the Sierra is *still* not on the G7 bandwagon. For many of us who don’t shoot extreme range, the G7 model is perfectly sufficient and will continue to be so.

No matter, I’m sure they will eventually get there.

I do think you did a good job avoiding the 4DOF/Litz drama, which to most of us shooters amounts to inside baseball. BOth 4DOF (marketing and all) and a G7 will provide useful trajectory calculations when you stay above the transonic range.

Thanks, Justin. I really appreciate your thoughts. I did specifically try to make this a broad perspective of the advancements. I’ve had lots of conversations with Bryan and his partners about their approach, and they’re exceptionally sharp guys and in a lot of ways were the original pioneers when it came to improving predictive ballistics and educating the shooting community about it. I honestly don’t know where we’d be without the contributions from the Applied Ballistics team. I also asked Dave Emary, long-time Chief Ballistician at Hornady, to read over this article and the next one, to give me feedback and make sure it was all correct. He was kind of enough to do that and then have a lengthy phone conversation about it. Dave is a wealth of knowledge, and has also made really significant contributions. I’ll actually highlight more of Dave’s work in the next post. It’s some of the most interesting research I’ve come across in a while. But Lapua was doing radar testing before any of those other guys, and Barnes Bullets bought their radar in 2011 (same year as Hornady) and has been doing testing ever since. Barnes is also the only company that has publicly published their Cd vs Mach curves, so cudos to them. And Sierra did make significant contributions in the early days, but not so much lately.

I tried to specifically point out work that each of those are doing towards the same end, without getting tripped up on the drama. I am a competitive and ambitious guy, but I’ve found collaboration yields the best results – even with competitors. And that’s not just an idealistic view. I almost never mention this, because I don’t want it to come off as bragging, but I run a $200M company with those principles that has averaged 30% growth year-over-year for more than a decade. So it’s not a naive view, although it is rare for a company to have an open-handed/collaborative approach in the marketplace. You can be a successful business and share information with competitors.

Thanks again for the kind words, and I really do appreciate you noticing how careful I was to present a balanced view without getting tripped up on the drama. Unfortunately, I’m afraid the more drama might be heading our way. It seems like we’re gearing up for an arms race when it comes to advanced ballistics engines. That can and will push advancement, and as shooters we’ll win in some ways because of that … but I’m also afraid it will fragment the community and stunt development, and a more collaborative approach might better serve the shooting community. I guess we’ll just have to wait to see how it plays out. Either way, this is pretty cool stuff!

Thanks,

Cal

I would be interested to see a table of elevation corrections using G1, G7, and a CDM for the same bullet/velocity. In theory a CDM should be superior, but I’ve had excellent predictions using G7s out to 2 miles. I’m curious to know how much difference (or how much closer the prediction might be) by switching to the CDM.

Hey, Adam! Good to hear from you. That’s a great idea. I actually can’t believe I didn’t do that for the post. I know that Litz published something like that in one of his books. I think it was one of the Modern Advancements in Long Range Shooting volumes. I think I remember what the results were, but I’d hate to misspeak, so I’ll have to look it up when I get a chance. I also have all the stuff in Applied Ballistics Analytics software suite on my computer too, so I can run the numbers for G1 vs G7 vs CDM myself too. I’ll try to find time to do that, and I’ll get back to you. Really, really great suggestion. That’s an important piece of putting this all into context. My gut is it will vary based on the bullet (i.e. some are a closer fit to the G7 than others), so I may have to do this for several bullets for it to be relevant.

Thanks,

Cal

Hey, Adam. Just wanted to let you know I replied to some other comments on this post with several examples showing the difference in what the predicted elevation correction would be based on which of these drag models you used: The Manufacturer’s published G1 BC, Litz’s G1 BC, Litz’s G7 BC, or the Applied Ballistics Custom Drag Model for that bullet. It does absolutely vary by bullet, and I’m sure there you’d need to look at a wider range of cartridges and bullets to draw conclusions on how much the difference is in general … but this should at least give a little context or concrete examples to see what the difference amounts to. Like I said in the post, it is really only when you stretch out into the transonic and subsonic range where the nuances of a specific bullet’s unique drag become valuable. If you’re well inside of the supersonic range, just about any drag model will work … but these are helping us reach distances that were considered ludicrous not long ago … and get first-round hits. Cool stuff.

Thanks,

Cal

Cal, thank you for posting this. I am not a PRS shooter, although I used to shoot ihmsa matches years ago. That said I still am fascinated by the science and want the most accurate trajectory calculation I can get for my hunting rifles.

Best regards,

Phil

Hey, Phil. This stuff is fascinating to me, as well. I love learning, but I also think this can help just about any shooter get more rounds on target as they try to stretch out to further distances. My love for rifles actually grew out of my love for hunting, so I am with you! Glad to hear you found this interesting.

Thanks,

Cal

Hey Cal – Its not often that I take issue with your posts, but I think this one might be giving people the wrong impression by saying they might be off “a couple of clicks” if they use G1 versus G7. Despite all the nice plots above showing G7 matching reality better in a variety of metrics, no where do you have a “but how much does it actually matter” plot… I expect more of you Cal!

Using your example bullet of the 115 DTAC I plugged both the .620 G1 (that Tubb advertises on the box) and the .312 G7 (that I use in my personal solution) and ran them both through Berger’s online ballistic calculator out to 1500 yards with

The *maximum* difference you see in drop between the G1 & G7 curves is .24MOA (at 1500 yards), and the *maximum* difference you see in 10mph 9 o’clock windage is .26MOA (at 1500 yards). At <=1000 yards, the difference is under .1MOA in both cases.

Now maybe it makes a much larger difference for other types of bullets and velocities but I'd argue that for anyone shooting 115 DTAC – G1 or G7 it simply doesn't matter.

Wow, David. I can appreciate your passion, but didn’t mean to get you riled up. I agree that some bullets have less of a difference than others. Tubb’s BC is more accurate than most BC’s you’ll find on the box, because he even explicitly says it was measured over 1000 yards. Like I said in the article, most manufacturers publish the BC they measured over the first 100-300 yards, which makes them less useful to long range shooters. So with the 115gr DTAC, right off the bat you’d expect the firing solution from Tubb’s published BC to be more accurate … and it is. I ran the ballistics below in Applied Ballistics Analytics software for 4 different drag profiles: Applied Ballistics Custom Drag Model for that bullet, Tubb’s published G1 BC, Litz’s average G1 BC, and Litz’s average G7 BC. The other inputs for atmospheric conditions, velocity, and rifle setup were identical. Then I exported those results into Excel and calculated the difference between the elevation corrections for each solution compared to the Custom Drag Model. The results are below.

In the example above, all of the solutions are within a click out to 1,000 yards. By 1300 yards, the solution based on Tubb’s G1 BC is 2 clicks different from the CDM and gets worse from there. According to AB Analytics, by 1500 yards it is off by 4 clicks from the CDM (equates to the shot being off by around 2 feet at that distance). The solution for the Litz G1 BC is fairly accurate inside of 1000 yards, although it is a click off from the CDM by that point and maxes out around 1400 yards by about a click and a half. The Litz G7 BC tracks well for the 6mm DTAC, but that doesn’t mean it does that same thing for all bullets. Now it being “off” by that much assumes the Custom Drag Model is correct, so it’s all relative – but the point is there is a difference as you stretch out the distance into that transonic range, which for this bullet and the environment I was running the ballistics for was 1350 to 1600 yards.

But, we should probably look at more than one example before we draw any strong conclusions on whether it is representative or not. The example below is for a 338 Lapua Mag firing a Berger 300gr OTM Hybrid bullet. In this example, I just compare the Custom Drag Model ballistics to what was produced based on the Litz G1 and G7 BC’s. Here all 3 models (CDM, G1, and G7) track within about ½ a click of each other out to about a mile (1760 yards), but then they diverge quickly. By 2150 yards, the G1 BC based solution is different by 2 clicks and different by 4 clicks at 2325 yards. In this example, the G7 BC solution tracks closer to the Custom Drag Model, but by 2200 yards they are different by 1 click. By the time you get way out there to 2600 yards, the G1 solution is different from the CDM by 8 clicks (around 6.5 feet at that distance) and the G7 solution is different by 4 clicks (just over 3 feet at that distance) … and in opposite directions, so there is a total difference of 1.2 mils between the two solutions! We are talking a difference of 10 feet between the G1 and G7 solutions! That’s not just enough to miss the target that is so far off that you might not even spot the bullet splash! While 2600 yards with a 338 Lapua may seem ludicrous, it’s exactly these types of shots that the new drag models are allowing people to make. I’ve personally made first round hits in competition at 2640 yards with a 338 Lapua using that exact bullet and load, so it’s possible!

Let’s look at one more example, which is basically a 7mm Rem Mag firing a Hornady 180gr ELDM bullet. In this example, you can see if you just plug in the BC off the box, your solution would be within a click inside of 800 yards, but you’d be two clicks off by 1000 yards. So you’d be on at 600 yards, but a couple of clicks off at 1000 … kind of like I mentioned in the article. But, by the time you got out to 1 mile, if you were using the G1 BC off the box the adjustment would be more than 7 feet different from what the CDM predicts! That’s because Hornady, like most companies, print the BC on the box that equates to velocities of 2500 fps or higher. Hornady publishes multiple BC’s similar to Sierra, but shooters have to know to go look for them, which is part of what I was trying to help educate the average shooter on with this post. If you use Litz’s BC’s the results track better, but the Litz G1 would still be off by 3 clicks at 1500 yards. The Litz G7 BC tracks well for this bullet, but it is still a click off at 1050 yards from what the CDM predicts.

And, I’d expect that there are a ton of other examples that would be off even more than the few examples I ran here. I didn’t even run examples for bullets made by companies that have historically been more “optimistic” with the BC they market for their bullets, which have proven to have been off by more than 10%. And I didn’t run the lathe-turned bullets used in big bores, which seem to be an even bigger departure from standard drag models. But, I don’t have the time to run them all … even if you expect more of me. 😉 I do all this for free to try to help other shooters with the time I have.

All of these simulations here also assume you are using a quality ballistic engine with all the current atmospheric information and you’ve measured your average muzzle velocity and all the other inputs accurately, which is also what I was trying to present in this post. That’s why I had the little diagram of the different parts that make up an accurate firing solution. All of that plays into what I meant in the opening by your solution being “a couple clicks off” at one distance or another. I wasn’t saying that bullet-specific drag models or G7 BC’s would result in a difference of a couple clicks over any distance. I would bet the majority of my readers aren’t doing at least 2 or 3 parts of what it takes to come up with a good firing solution, so in this post I was trying to help educate people on what those elements were. Each element might just present a slight error, but they stack and can become significant enough that you don’t trust your firing solution like you should be able to. I also wanted to show the progression of how our solutions have become more and more accurate, but you only get the benefit of that if you’ve kept up and aren’t still doing it the way you were 10 years ago.

G7 = -.000228 + 0.512*G1 , r2 = 100% so if you know one then you know the other without measuring.

The G7 BC parameter does not differentiate ballistic performance any better than G1 for any given bullet as you can see from this correlation. It is only their respective drag curves which tell a different story.

Wow, Charlie. I never knew that little conversion formula, so thanks for sharing. I totally agree that the number means nothing, but the real difference is the underlying drag curve the ballistic solver is applying that coefficient to.

Thanks!

Cal

Hi Cal,

sorry if I’m breaking the threading in your post somehow. When I click on the reply link it just brings me down to the bottom of the page where it looks like I’m leaving an all-new comment. To clarify I believe that GMX/TSX/LRK are all swaged, not lathe-turned, despite being copper solids. I could be wrong about that, but luckily the distinction isn’t really that relevant to the conversation either, and doesn’t detract from your points.

My primary motivation is not that I don’t want to ruin meat, but rather that I don’t want to lace it with lead or have to pick out fragments while processing it. Nothing’s worse than letting a piece of lead or jacket slip through the grinding process and then watching a loved one bite down on it and spit it out onto the plate (ask me how I know). Clearly a large amount is also vaporized straight into the meat as evidenced by inherently doomed attempts to piece back together the “retained” weight of a lead bullet after the fact. I’ve often wondered why this doesn’t seem to concern people. I also once saw a video on this out of California by (IIRC) a game warden who brought an x-ray out to an animal carcass, shot it with lead, then used the device to reveal a large amount of metallic “splash” in the animal that would simply be impossible to extricate.

That said, I hear you on hunting performance. Softer bullets simply expand/fragment easier, which is to say at lower impact velocities. I make sure that my impact velocity with copper is always north of 2k for exactly this reason, but the flipside is that to retain that impact velocity at longer ranges, I would benefit from better-shaped bullets. 2k minimum is admittedly terrible compared to what lead bullets like the ABLR can do. But that terrible velocity retention for non-VLD coppers is my big beef. And it may be that it’s impossible to engineer a solid bullet that can do this, without it being a lathe-turned Gucci projectile, but things like the A-Tip give me a bit of hope with their potential to act as an “expander” for lack of a better word, as well as the tuning possibilities for CoG.

Cal – excellent post as always. Thank you for all the detailed research and simplicity of language.

Offering a minor correction, in your post you state the Lapua ballistic solver app only being available for Android. It is in-fact also available for iPhone. I’ve been using it for the last 2yrs and it’s excellent. The 6DOF data is spot on for me and both the Lapua and TRASOL solvers offer almost identical elevation data…but vary a little with windage.

Thanks again for all you do!

Cool. I was just going based on what it said on Lapua’s website, so sorry for the confusion. They must have just forgot to update it after they released the iOS version. I’ll get that corrected in the post.

Thanks,

Cal