The goal of this field test was to quantify the temperature stability of the popular Hodgdon H4350 and Varget powders and compare those to IMR’s new Enduron line of powders. To do this we carefully measured muzzle velocities of meticulously loaded ammo over a huge range of temperatures.

This test was conducted by Patrick Middlebrook. Patrick is passionate about the art of precision rifles. He’s a great shooter who has competed in numerous local matches, and several national PRS matches. He is also a 5-star handloader. I’ve learned a ton from him! Patrick has become a good friend of mine (Cal, the author of PRB), and he mentioned wanting to do a powder test. We collaborated on some ways to approach it, and Patrick took it from there. Patrick is a meticulous guy, and he put in the work on this test. I hope you find it as interesting as I did. Thanks Patrick!

94% of shooters finishing in the top 100 in the Precision Rifle Series (PRS) choose to run one of gun powders from the Hodgdon’s Extreme Series of powders, like H4350 and Varget (see the data). While those powders may not always produce the fastest muzzle velocities, veteran shooters have learned to trust that Extreme powders will provide consistent muzzle velocities across virtually any environment. That’s because the “Hodgdon’s Extreme powders perform just as well at 125° as they do at 0°. Using an exclusive extrusion process and exacting quality standards, Hodgdon has created a line of propellants that performs better at hot and cold temperatures than any other powder on the market.”

IMR recently released a new line of powders “with Enduron Technology,” which is also marketed to have “extreme temperature stability.” … Sounds familiar! These new powders should compete directly with the Hodgdon Extreme Series, which gives shooters more powder options to consider.

I’ve heard shooters say great things about the IMR Enduron, and some even say it is just as consistent as Hodgdon Extreme. I wanted to investigate these claims, because “consistency” is a must if you want to be competitive. So I decided to test 4 different powders that are ideal for the majority of calibers used in long-range, PRS-style matches:

- Hodgdon H4350 – This is an overwhelming favorite for mid-sized cartridges like the 6.5 Creedmoor, 260 Remington, 6.5×47 Lapua, 260 Remington, 6mm Creedmoor, 6×47 Lapua, 6XC, etc. Over 70% of the top PRS shooters load their ammo with H4350 (see the data).

- IMR 4451 – IMR already had powder named “IMR 4350” with a similar burn rate to Hodgdon’s H4350, but it lacked temperature stability. So they designed IMR 4451 to burn in the same cartridges AND be more temperature stable. Some shooters have told me IMR 4451 allowed them to squeeze a little more velocity out of their rifles, compared to H4350. We can’t confirm or endorse those claims, but it might be something to keep in mind when starting load development.

- Hodgdon Varget – If you have been to any rifle match and talked about reloading, it would be hard not to hear about Varget. While you may not have seen this powder in person, because it seems to fly off the shelf faster than any other powder … it does really exist! When Varget was first introduced, it quickly gained popularity among predator hunters and benchrest shooters shooting the 22-250 and 223 Remington. It has also became a favorite powder for those shooting 308 Win, 6.5×47 Lapua, 6mm Dasher, and other mid-sized cartridges. Varget has a faster burn rate than H4350, but there is some overlap between the two in terms of the cartridges that they’re ideally suited for.

- IMR 4166 – This powder has very similar burning characteristics to Hodgdon Varget, and can be used in the same array of calibers. The good news is this powder is easy to find and seemed to have great results in my test.

Why Should I Care About Temp Stabile Powders?

A change in temperature can affect the trajectory or ‘flight path’ of the bullet in two well-known ways:

- So long as altitude, barometric pressure and humidity remain constant, an increase in air temperature will cause a flatter trajectory due to a lower air density (less collisions with ‘air particles’ per unit length of flight path).

- The same increase in temperature also causes the nitro cellulose based powder inside the cartridge to burn at a higher rate, producing approximately four times the Point of Impact (POI) shift than just air temperature alone.

Just how much does an increase in temperature affect the powder burning-rate? Some powders are more susceptible to temperature effects than others and will burn faster than others.

– Excerpt from Temperature Effects On Zero on KestrelMeters.com

“The initial heat condition of your powder will affect the burn rate,” I heard Bryan Litz explain at his recent Applied Ballistics Seminar. That means swings in ambient outside temperature can affect your internal ballistics, which will directly affect your muzzle velocity, which will change your bullet’s trajectory. Some powders are more affected by changes in temperature than others. So if your goal is first shot hits and you may shoot in a variety of conditions … you should care about temperature stable powders.

Earlier this year, there was a PRS match in Nebraska where competitors had to shoot in the snow, and some of the same competitors will be found in Oklahoma shooting “The Heat-Stroke” match mid-July where temperatures could exceed 100 degrees! I’ve been at matches where you start off shooting in 50° weather in the early morning, and the day heats up to almost 90° by mid-afternoon. When you have temperature swings like that, the muzzle velocity of your bullet could increase by 50 fps or more … which could be enough to completely miss a target.

There are so many variables involved in hitting long range targets that we need to always be looking for variables to eliminate. If we can reduce the odds that a load might shoot faster in the heat and slower in the cold, it’s a worthy pursuit!

At the Applied Ballistics Seminar in March, Bryan Litz gave his rule of thumb for how muzzle velocities may vary with temperature for different types of rifle powder:

- Good Double-Base Powders: 1 fps per degree Fahrenheit

- Average Single Base Powders: 0.3-0.5 fps per degree Fahrenheit

- Best Single Base Powders: 0.1-0.2 fps per degree Fahrenheit

(For more info on single/double base powders, check out this article by Chuck Hawks.)

Bryan specifically cited Hodgdon Extreme Series powders as one of the least temperature sensitive powders he’d used. He also made it clear that no powder is completely insensitive to temperature. Your muzzle velocity WILL vary based on ambient temperature, regardless of what powder you use. So while we can seek to mitigate that variance … at this point, no powder allows you to completely eliminate it. But, you can minimize the effect by making a wise powder selection.

I’ve seen many shooters pick a load using one of the Alliant Reloader powders, simply because it gave them the highest muzzle velocity. But, many have found those powders to be very sensitive to temperature. It’s unfortunate when you see a shooter at a match that seems to be hammering targets dead center early in the morning, but as the day heats up they start missing more and more targets. They lose confidence in their dope, question their rifle or scope, and generally just spiral into frustration. But, many never make the connection that it could be a poor powder selection that caused their trajectory to change so dramatically.

It’s even worse if the temperature gets really hot, because the guys who developed a “warm” load with a temperature sensitive powder will start blowing primers … or worse. If they were already close to max pressure when they developed the load, then any increase in temperature can turn into a dangerous situation. To avoid that scenario, when using a temperature sensitive powder the smart choice is to load down so you’ll remain within the range of safe pressures even when the temperature rises. But when you do that, it likely eliminates any muzzle velocity advantage those powders may have provided over those that are specifically formulated to be temperature stable.

The Test

The goal of this test was to quantify the temperature stability of the four powders we’re interested in. To do this we’re going to measure the muzzle velocities of load ammo for a wide range of temperatures. Let me quickly run through the setup of how the test was conducted.

Rifle & Caliber Selection

I wanted to pick a caliber that is widely used in PRS-style matches (see what they use), and that would burn all 4 test powders efficiently. It didn’t take long to realize that a wise caliber choice was the 6.5×47 Lapua. There are a multitude of shooters using H4350 and Varget in their 6.5×47’s with awesome results. There were also more PRS competitors within the top 100 finishers using the 6.5×47 Lapua than any other cartridge (see the data). I was fortunate enough to perform the test in style, with a full TS Custom rifle build that a friend let me borrow. It had a 22” barrel, which is shorter than average, so your velocities may obviously vary from our results.

Velocity Measurements

I recorded the muzzle velocity of each shot using both a LabRadar Doppler Radar and a MagnetoSpeed Chronograph. The LabRadar is a new type of device that allows you to measure muzzle velocity within at least +/- 0.1% of the reading. So if our muzzle velocity is 2,700 fps, the measured velocity should be within about 2 fps of the true muzzle velocity. That’s pretty amazing! It actually tracks the bullet out to about 80 yards, taking numerous velocity readings along the way. The muzzle velocities collected proved to be very similar between the two devices, which gave me a lot of confidence in the data. Both of these devices seem to be much more accurate and dependable than traditional light-based chronographs. But to try to mitigate any potential measurement errors, we averaged the velocities collected for each shot from both devices.

Loading Procedure

The ammo was meticulously handloaded with what we believe to be the best equipment available. Every good load starts with good brass. The availability of quality brass has been such an issue that many shooters choose which caliber of rifle to build based upon what they can find good brass for. Lapua is commonly accepted as the gold standard when it comes to brass quality, and for good reason. Lapua brass is very consistent and tends to last longer than other brands. I’ve heard shooters getting 20 loadings on 6.5×47 brass (if annealed). Being able to reuse it that many times could mean Lapua is the cheapest brass you can buy! I used brand new Lapua brass and expanded all of the necks with a Sinclair Expander Mandrel to ensure the necks were consistent with no dents. Neck tension is commonly overlooked, but if you want consistent single digit SD’s (i.e. your ammo has very consistent muzzle velocities, with standard deviations of less than 10 fps), you’ll need consistent neck tension.

Each case was then sized using a Whidden Gunworks Full-Length Bushing Die. The neck was sized to provide 0.002” of neck tension when loading Berger 140gr Hybrid bullet. Match-grade CCI BR-4 Primers were seated using an Accuracy 21st Century Priming Tool, which provides a very good feel and is very consistent. The tool also allows you to fine-tune the seating depth, although I’ve found my best results come from seating the primer all the way to the bottom.

I then used the Prometheus Gen II Powder Scale to throw all charges. I have checked the Prometheus several times on a high-end Sartorius analytical scale, and each time it confirms what I already know: the Prometheus is accurate down to a single kernel of powder! The Prometheus isn’t cheap (starts around $3,800), but if you reload as much as I do, it can save a ton of time, and allows me to go to the range instead of sitting around loading all day. I loaded each case at what I knew would be a mild to medium load, in order to avoid pressure spikes. None of the loads were “tuned” for the specific rifle we were testing with.

When using Berger bullets, everything tends to be very uniform … but never perfect. For PRS-style matches, I don’t find sorting Berger Hybrid bullets in any form or fashion helps me put more rounds on steel. I’ve experimented with “improving” Berger bullets by pointing them and weight sorting them, but it had virtually no effect on my groups downrange. I did see my BC improve slightly by pointing. So if you’re looking for every last advantage you can get, pointing may be worth your time! But I didn’t do that in these tests. I seated the Berger 140gr Hybrid bullets using a Whidden Gunworks Bullet Seating Die, which have proven to provide very consistent and repeatable seating depth.

At the end of all this, I had a box of 25 loaded rounds of 6.5×47 Lapua ammo for each of these powder charges:

- 39.5 grains of Hodgdon H4350

- 39.5 grains of IMR 4451

- 36.5 grains of Hodgdon Varget

- 36.5 grains of IMR 4166

Freezing & Heating The Ammo

10 loaded rounds from each group were brought down to 25° F by placing them in an iced down cooler (mixture of dry and regular ice). They sat in the cooler for 4 hours to ensure they were evenly acclimated to the temperature. A thermometer was placed in the cooler with them to measure what the final temperature ended up being.

Another 10 loaded rounds from each group were brought up to 140° F by exposing them to a heating blanket. This might sound excessive, but if you leave your box of ammo out in the sun or on the dash of your truck … it can get up to this temperature. I brought the heating blanket to the range with me, and let all the cases heat up for 2 hours as I prepared the test. Once again, a thermometer was placed alongside the cases to measure the final temperature.

The remaining 5 loaded rounds from each group were used as the control for this experiment, and they were kept at the ambient temperature of 65° F.

Powder Test Results

We’ll view the results in a few different ways. Let’s start by simply looking at the overall variance in muzzle velocity we measured over the entire range of temperature extremes:

You can see Hodgdon H4350 had the least variance in muzzle velocity, with just 25 fps over the 115° swing in temperature! That is very, very low. Hodgdon Varget was the second least temperature sensitive powder in this test, with 46 fps of variance in muzzle velocity between temperatures of 25° F and 140° F. IMR 4166 performed very similar to Varget, and proved to be fairly insensitive to large swings in temperature. IMR 4451 had the largest swing in muzzle velocity of the powders tested, but keep in mind just 68 fps over 115° F swing is still a good performance.

If we would have included powders like Alliant Reloader and others, which are notorious for large swings with temperature … you would see much larger numbers on this graph. We didn’t include those, because honestly … we’re only personally interested in using powders that are temperature stable. We already know those aren’t, so there was no sense wasting time and barrel life on them. I just wanted to put the results in context; all four of these powders outperform most others out there.

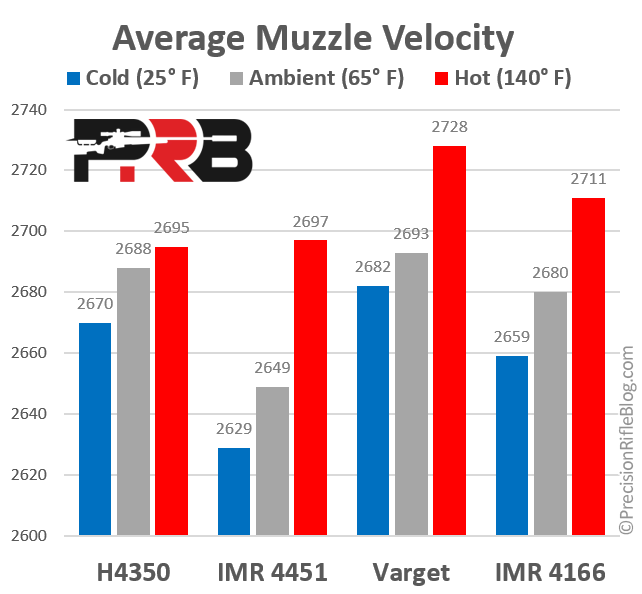

Here is a view of the underlying data, which shows the average muzzle velocity for each group of ammo:

Remember these were all for the 22” barrel on our test rifle, and your mileage may vary. We also just picked safe loads for each powder, and didn’t do load development to see what velocities for each powder would be at max pressures. So although Varget produces the highest velocities for the loads we tested, it’s more than plausible that one of the other powders could achieve higher velocities and still be within safe pressures. Our goal in this experiment was simply to quantify how much the muzzle velocities of the powders varied with respect to temperature.

One thing you might notice in the chart above is that the variation in velocity does NOT appear to be perfectly linear across the full range of temperatures. By that, I mean the change per degree from 20 to 65 might be smaller or larger than the change per degree from 65 to 140. That may be surprising, but it’s something I’ve heard a couple industry pros notice as well. That’s why I’d suggest you test your own loads at various temperatures, and document what you find. The Kestrel Elite Weather Meter with Applied Ballistics allows you to enter a table of muzzle velocities for different temperatures, and it will automatically use that data to infer your initial muzzle velocity for the current conditions. That is a pretty cool feature, and as far as I know it’s the only ballistics engine that provides a way to automatically account for this type of variable. But it’s only valuable if you have good data to support it.

One thing you might notice in the chart above is that the variation in velocity does NOT appear to be perfectly linear across the full range of temperatures. By that, I mean the change per degree from 20 to 65 might be smaller or larger than the change per degree from 65 to 140. That may be surprising, but it’s something I’ve heard a couple industry pros notice as well. That’s why I’d suggest you test your own loads at various temperatures, and document what you find. The Kestrel Elite Weather Meter with Applied Ballistics allows you to enter a table of muzzle velocities for different temperatures, and it will automatically use that data to infer your initial muzzle velocity for the current conditions. That is a pretty cool feature, and as far as I know it’s the only ballistics engine that provides a way to automatically account for this type of variable. But it’s only valuable if you have good data to support it.

And here is one more view of the results, which shows how much the average change in muzzle velocity for every one degree of temperature change across the full range of temperatures.

The results were interesting, to say the least! Both company’s claim their powders perform better than this experiment indicated … and that could be the case in different conditions. I did notice both Hodgdon and IMR used Winchester primers in their tests. I chose CCI BR-4 primers, because they provide world-class standard deviations with my handloads, and because top shooters I trust have always recommended either CCI or Federal. It’s interesting that at every match I’ve been too, I’ve never heard of anyone using Winchester primers. (Note: Hodgdon and IMR appear to be sister companies of Winchester Powders, so that could have influenced their choice.)

Many accomplished shooters put a big emphasis on using a temperature stable powder, but could we as shooters have overlooked the importance of a temperature stable primer? Perhaps a test for another day!

I will note that the H4350 loads in my test had an average SD of 6 fps! The Varget load also had a single digit SD. I did not get single digit SD’s with both IMR powders, but they were still respectable. I’m sure I could fine tune the loads for any of these powders and achieve fantastic results.

It seems like we can conclude that this lot of H4350 is measurably more temperature stable than the new IMR Enduron 4451. In fact, Hodgdon H4350 had about half the variance of any other powder tested. IMR 4166 performed very similar to Hodgdon Varget, when it comes to temperature stability. That’s great news for those shooters struggling to find Varget in stock! I wouldn’t hesitate picking some up and developing a load tomorrow. In a time when it seems like good powders are always “Out of Stock, No Backorder,” it’s great to have a few more options!

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

Thanks for the time and effort you put in to educate us….. grateful.

You bet, Caylen! Glad you found it helpful.

Thanks,

Cal

You didn’t cover the condition of the rifle during these tests. Although the powder may be at a particular temperature as it’s placed into the feed ramp, it’s quite hard to predict what the temperature of the load will be during the moment of firing – esp. if it’s been sitting in the chamber for more than a few seconds – brass will conduct latest heat quickly.

I find all this stuff quite frustrating – so I try to use the least temperature sensitive powders as a matter of course – since I go from shooting in snow to shooting in blazing heat (and if the ammo is in the sun for more than 1 min, who knows what temperature it is inside the case – certainly more than 140F).

Great work though.

Hey, FarmerB. I didn’t know the answer to your question, so I pass it on to Patrick. Here is his reply:

That was how I figured it was run, but I didn’t want to assume anything. It was a good question.

Thanks,

Cal

Cal, you have gone above and beyond with this blog. I didn’t know how to reach out besides posting this. I am just getting into long range shooting, I have a Ruger Percision in 308, I would like any advice your willing to give on getting started. I.e. Products needed, how to make accurate dope cards, really anything you recommend I will go with. Your blog has gained my trust 100% and I figured asking you would be a great place to start.

Thanks

Hey, Clay. That’s a big question to try and address in the comments, which is why it took me a few days to compose a response. I’ll try to help as much as I can.

If I were just starting out, I’d focus less on gear (beyond a capable rifle setup like you already have) and more about your fundamental marksmanship and understanding of long-range shooting and best practices on employing your long range rifle. The shooter is virtually always the weakest link, so you’ll get the most return by spending time and energy there. Here is what I’d suggest to any new shooter:

1) Take A Class – I’d find someone who knew what they were doing and take a 1-2 day class with them, where they teach you some fundamentals in a classroom setting and then have live-fire practice as well. This will probably do more to help your shooting and get the most out of your gear than anything else you can do. It just puts you on the fast-track, and can help you learn in a few days what might take years if you just practiced and tried to learn everything yourself. Here are a few options I know of:

If you absolutely can’t do a class, you can learn some of the same things from DVD training … but it isn’t NEAR as effective. Here are a few you might consider if you had to resort to the DVD option:

But, seriously a DVD is no where near as effective as in-person, instructor-led training. I’ve personally taken some of the classes above, and just got back from Gunwerks LRU a couple weeks ago. I’m still learning stuff in these kinds of courses! If you bought a super-expensive camera, it would be wise to read the owners manual to understand it’s capabilities and get the most out of it. I see some people with $3000 camera setups that just always leave it on “Auto” mode. They have capable gear, but they don’t realize how much more they could get out of it if they’d just learn how to take advantage of everything it has to offer and use it the way a pro would. A quality long-range class is like that. Those instructors can help jumpstart you into this world and skip years of learning things that hard way. Regardless of your current level … I promise you’ll learn a lot. I know I still learn a lot from these training events. I hope to take another one in 2017, and might continue to take one a year forever.

2) Read Litz’s Applied Ballistics For Long Range Shooting book – This will give you a great foundation to not just ballistics, but things like making sure your scope is setup correctly, how to select the best bullet for your application, and a bunch of other very helpful stuff. It will also help you put into context how much different elements matter.

3) Enter a local rifle competition – While you may not place competitively your first match, that isn’t the point. I promise you’ll learn A TON in your first competition. I sure did. It also gives you a chance to watch other people who are really passionate about the sport and see how they’re running their gear … and maybe even get to try it out before you sink money into it. Plus you’ll get to meet some other people who are into this stuff, and maybe even make a few friends that can help you along.

If you do those 3 things, I bet you will make leaps in your ability. Honestly, I’d bet you’d never find anything that would give you a return on investment (in terms of your ability to get rounds on target) as much as those 3 things would. Past them, it would just be a steady diet of practice and honing your skills.

Beyond that, we start getting into specific gear recommendations, and the majority of that stuff comes down to personal preference. The What The Pros Use series of posts might be helpful, but then again … don’t think those guys ended up in the top 100 because they have good gear. They end up there because they have put A LOT of rounds down range practicing. There are no shortcuts there. Good gear compliments a good shooter, but it can’t make one.

I hope this helps. I almost just wrote a whole post in the comments, and maybe I’ll turn this into a post at some point. It was a great question, and I do want to help you out. This is almost exactly what I told a good friend of mine when he started getting into this. Best of luck to you!

Thanks,

Cal

Interesting test. Thank you for the time, money, and effort invested into this test. I think I may do the same with a few powders slightly faster out of my 6mm BR. I wanted to see the differences between N135, IMR8208, H322, and Benchmark.

That’s great, William. I hope this website inspires others to do similar tests. The setup was pretty straight-forward. You just need consistent ammo and a good way to measure muzzle velocity, so that the powder is the only variable. Best of luck to you!

Thanks,

Cal

Great job!

u should test AR comp, its a varget substitute…

Testing is all done, Ring. We don’t have plans to test any other powders at this point. But, you should go test it if you’re interested in that powder. This is pretty straight-forward stuff.

Thanks,

Cal

Excellent article. I was going to change to IMR 4451 from H4340 for better temperature stability. Not now after reading your article.

Yeah, this definitely shows why H4350 is sooooooo popular among the top shooters. I use a ton of it myself in my 6XC and 6.5 Creedmoor. It’s hard to find it in stock anywhere, I’m afraid I might have just made it even more difficult to find! 😉 Oh well. Glad to help educate people. Hope it helps you get more rounds on target.

Thanks,

Cal

Strelok Pro also has a muzzle velocity/temperature calculation.

Interesting. I guess I haven’t heard of that. Thanks for sharing. It’s probably a pretty full-featured engine if it has a place to account for this.

Thanks,

Cal

Thanks for the assessment and information cal

Well, I have to blame Patrick for conducting this test. He was the one who came up with the idea and went out and gathered the data. I think he did a great job.

Thanks,

Cal

I live in the Las Vegas, NV valley. It was 110 F. here today.

I’m just getting into competitive shooting 6.5 CM in an RPR) and I’ve chosen H4350 several months ago after reading all the research I could find on its temperature stability. Looks like I chose wisely. Most of the people on the “6.5 Creedmoor” website also use H4350. It’s not always easy to find, even in a metropolitan area like ‘Vegas with many gunshops.

I understand there is also an Australian powder that has a similar temperature stability.

Hey, Eric. I use it in my 6.5 Creedmoor and my 6XC, and it performs great in both. And I live out in the desert as well, with temps busting into the 100’s … but not quite 110 yet. I flew through Vegas a couple times last week and I think it was 100+ both times. That’s brutal!

And it is hard to find. Very hard to find. I actually went on Gunbroker.com before I published this to try to see if there was any available, because I figured this post could exasperate the problem even more. But there wasn’t any up there for sale. I can’t remember the last time I saw it on the shelf. It’s literally been years.

As I understand it, H4350 and Varget are actually made by an Australian company. They are sold under a different name there (I think AR2209 and AR2208), but I’m not sure if they’re 100% identical. That’s just what I’ve read. There may be another Australian powder that you’re talking about, but that just sparked my memory.

Thanks,

Cal

AR2209 and AR2208 are indeed the same powder. You can prove this by looking at the MSDS datasheets on the Hodgdon site. The company is actually now owned by the French Thales. I have just seen Varget and H1000 turn up here (Europe) for the first time in several years.

Very cool! Thanks for the info.

Sorry – that wasn’t clear – I meant Varget = 2008 and H4350 = 2209.

Hi. I find all your posts very usuful and relevant. Can you give us a better indication of how the Magneto Speed chronograph measured up to the doppler radar?

That is a great question. A few months ago, I shot 100 rounds through 3 chronographs: the LabRadar, MagnetoSpeed, and Oehler 35p. I intended to write a post about that, but just never have. So I’ll try to give a quick synopsis. The LabRadar and MagnetoSpeed tracked very similarly. They weren’t off by more than a couple feet per second on any one reading. The LabRadar picked up around 95% of the shots, while the Magneto Speed picked up 100% of the shots. Shooting through the Oehler might have affected the LabRadar’s ability to track the bullet, so if you didn’t have that in front of it you might have got all 100 shots.

While the Oehler 35p was my go-to chronograph and considered the gold standard for years … it wasn’t great compared to the other two. In fact, after that test … I said I wouldn’t ever get it out and set it up again. First, it’s a pain to setup compared to the others. It’s also very fickle (poor or inconsistent lighting, wind, or minor details in setup can skew the results). And it varied up to 10 fps or more from the other two devices. I replaced a sensor and the batteries in the Oehler 35p, and also was meticulous in double-checking all the distances and angle of the sensors before the test. But the readings just didn’t seem to be as consistent as the LabRadar or MagnetoSpeed. Now I was testing the Oehler in it’s default configuration (standard 4 foot screen spacing, and didn’t have it in a light box). If you spread the screens to 8 foot or even 12 foot, you’d be able to improve the performance. At the same time, that would make it even less convenient.

Hey, I loved the Oehler 35p. I was it’s biggest fan. But in my view, the day and age of the light-based chronograph are over … at least for me. The LabRadar is the ultimate solution in my opinion (at least for consumer/prosumer options under $1k). You can literally set it up and be ready to shoot in less than 30 seconds, and I believe it’s the most accurate device. It doesn’t affect barrel harmonics like the MagnetoSpeed, so that means you can record muzzle velocities and shoot for groups or do load development at the same time. In fact, I even shoot long range and have the LabRadar setup beside me. That’s especially helpful when you’re truing ballistics, because you know what the exact muzzle velocity was for that bullet and drop. If you have a really good rangefinder, you can do a really good drop test (at least as good as possible for a drop test). Bryan Litz has mentioned he’s also been very impressed with it, although he hasn’t published any test results yet.

The MagnetoSpeed certainly wasn’t lagging far behind the LabRadar. Like I said, it was always within a couple fps. Honestly, there wasn’t a clear way in my test to know which one was right … so it’s somewhat blind faith that makes me believe the LabRadar was the one that was closer to right. But I have talked to the guy who invented the LabRadar, and know a little about the technology behind it … and it seems pretty solid. He actually told me its AT LEAST accurate to 0.1%, but in reality its probably a lot better than that. I can’t confirm nor deny that, but it just gives me a pretty high belief level in the product. A good test might be to have 2 of them side-by-side, and I tried that one day … but couldn’t get them both to read at the same time. I was in a hurry, so I didn’t spend time troubleshooting them. I think there was some interference, and I’m sure I could figure it out if I spent the time on it. I actually have 2 friends with them now, so I could potentially have 3 set up side-by-side, and if they all gave the same exact reading for each shot … it seems like that would give you a lot of confidence in the output. The ultimate experiment would be to shoot 3 of them like that, and also shoot over a 12 foot Oehler or one of the commercial-grade chronographs like Bryan has. I’d bet he does that experiment at some point, and I can’t wait to read the results.

For $300, the MagnetoSpeed is a HUGE value, and I’ve never seen it not get a reading on a shot. I personally believe the LabRadar may be more accurate, it’s a lot easier and faster to setup, and it doesn’t hang off the barrel so it won’t affect your shot. When you’re testing things like I have been, that can be important. But, the LabRadar is twice as expensive (around $600 last I saw), so it just depends on what money means to you. If you have the money, I’d recommend the LabRadar. But the MagnetoSpeed is a killer value. I’m convinced no chronograph out there can offer the value that the MagnetoSpeed does for the price.

Thanks,

Cal

Cal,

A couple of things: One is that after I ordered my own copy of the Labradar instrument, I spoke for a time to the U.S. seller, and he said he had done the two-unit test with, IIRC, a 9 mm bullet. He said the two units were within 1 fps of each other except at the longest range, where he would sometimes see 2 fps disagreement. But that’s getting close to the limit of the device’s reading ability, so it could be slight sensitivity differences making one unit noisier at that range than the other. Could also be a random bit error artifact. I don’t have a way to know.

The other thing is a question: Was the 2 fps reading difference with the Magnetospeed consistently higher for the Labradar? Five or six years ago, a retired radar engineer who had made a Doppler unit for his personal use shared some output from it with me that he’d made shooting a 40 S&W pistol. Its output was a continuous velocity vs. time plot rather than velocity vs. distance. It showed something Harold Vaughn had demonstrated with a magnetometer rig in his book, Rifle Accuracy Facts, about 15 years before him, and that is that over the first few calibers of bullet travel beyond the muzzle, muzzle blast further accelerates the bullet a little. For his pistol it was about 3.5% and for and Vaughn’s 270 Winchester rifle, it was about an additional 3%. Presumably a change in barrel length would affect the number. The radar trace showed the velocity rise and then start the normal drop due to drag very clearly. My assumption is that this post-muzzle acceleration would fool a Magnetospeed into reading a little bit low, as the bullet would not be quite done accelerating when it crossed the first sensor. I read somewhere the Army found muzzle blast influence in artillery to be done in the first 11 calibers beyond the muzzle, but don’t recall learning the barrel length(s) in calibers or peak-to-muzzle pressure ratios they found it for.

Great question. It took me a while to go back and dig up the data, but I finally found it! I had 5 different cartridges/loads I fired over all 3 chronographs. The average muzzle velocity was slightly higher on the LabRadar on 3 of them, and the MagnetoSpeed was slightly higher on 2 of them. The Oehler was 20-30 fps slower across the board. So the LabRadar and MagnetoSpeed don’t seem to be systematically slow or fast relative to the other.

And dang, that Harold Vaughn Rifle Accuracy Facts is a good book, isn’t it?! I bought several books like that all at the same time, and I was slowly making my way through all of them … but that one is something special. I wish I could’ve collaborated or at least had a good conversation with Mr. Vaughn. I bet you could learn a lot from a guy like that. That is an interesting idea about the post-muzzle acceleration, but it seems like those guys may have corrected for that in the software. Next time I see them, I’ll definitely ask! You’ve got me wondering!

Thanks,

Cal

Cal, I deeply appreciate the work that you do. I wanted to weigh in on the LabRadar and MagnetoSpeed conversation. As far as accuracy I would think that the MagnetoSpeed is the more accurate measure of the Velocity of the bullet as it exits the barrel.

My reasoning for that conclusion, is based the fact that LabRadar obtains its velocity measurements based on Continuous Wave Doppler Radar. That means they are subject to what is known is the Doppler Effect.

In simple terms a policeman using a radar gun would need to be directly in front of the approaching vehicle to get the most accurate measurement of speed. Any movement to the right or left would lower the displayed speed. The same is true for LabRadar which is to set up to the right or left of the rifle, thus it is at an angle to the bullet path. I suspect that the readings of the LabRadar were slightly lower than the readings from the MagnetoSpeed.

The good news is a shooting buddy has a new LabRadar and I own a MagnetoSpeed and we are going to find out for ourselves this weekend. Once again thank-you the work that you do.

That’s an interesting idea, but I looked back at the data and I ran 5 different cartridges/loads over all 3 chronographs. In 3 of those cases, the LabRadar had a faster average muzzle velocity, and in 2 cases the MagnetoSpeed was faster.

They suggest you place the Doppler beside the rifle, and it seems like they could account for that offset as they interpret the results and correct for it. The center of the device is usually less than 12″ from the barrel, which isn’t much when you’re talking about measurements taken 50-80 yards down range. But, after reading what you said it makes me believe you might could skew the readings if you placed it further from the barrel.

Honestly, you sure might be right about the MagnetoSpeed being more accurate. It’s blind faith either way, because I can’t really think of an affordable way to figure it out. If I had access to a full-blown, professional doppler setup or maybe a commerical Oehler device like what Sierra or someone uses, you could probably figure it out. It’s funny to think it’s hard to know what the “real” muzzle velocity is, but that is what you’d have to figure out to answer that question … and it’s just not an easy thing to answer.

Thanks,

Cal

Thanks for sharing these results. As with everything else from this blog it’s very interesting and helpful!

One thought.

The jump from ambient to hot is where powders really differ.

Keeping ones ammunition out of the sun is relatively straightforward. The cold to ambient may be more (but not completely) representative of keeping ones ammunition in a bag over the cause of a day.

It’s worth noting that in this scenario Varget is about twice as stable as the rest, who in turn are pretty much equal.

Just an observation.

Thanks again for a great blog.

Christian

Thanks, Christian. Glad to hear you find the content helpful. I definitely agree with you to a point. 3 of the powders tested showed more variance from 65 to 140 than they did from 20 to 65, and I wouldn’t be surprised if that trend held true for the majority of powders. But, H4350 had more variance on the low end (20 to 65). So the statement “The jump from ambient to hot is where powders really differ” is mostly true, but not universally. That’s why we test this stuff! There are usually a few outliers that ignore the “rules of thumb” that we might be using.

And you’re point about Varget being more stable in that lower temperature range is a great one. You definitely have an eye for detail! I hadn’t made note of that, so I appreciate you pointing it out. For those hunters (like me) who like to be out in the bitter cold, that could be a compelling argument for developing a load around Varget instead of one of the others with more variance in that 20 to 65 degree range. I appreciate the thoughts!

Thanks,

Cal

All the powders tested are quite stable ,I run an .284 with RS60 (Reloder !7) man that is temeramental ve are not talking 1-°C/F but close to 3fps/1°C .

Some powders ‘cheat’ ,making and immpresion of stability with a certain flat line band. Vihtavouri N140 is one such powder its dead stable in 18-23°C temperature range ,which covers temps much of the year in central Europe . but once you are out of that spot if gains and looses speed. Testing reveals things ar enot linear for many powders , some have certain temp ranges where nothing much happens and then a steep drop or climb ,you might avrage that but its not real.

Wow. Thank you so much for sharing some data on the other powders. That really helps put these results in context of the larger picture. And that’s interesting about the N140. I guess that corroborates what I found related to the change in muzzle velocity not being linear with temperature change. I agree that you shouldn’t just take the average. I have multiple points entered in my Kestrel, and that seems to have really helped put me in the center of a target on the first round. It’s been surprising how accurate it is after I started putting in those muzzle velocities by temperature instead of just one universal muzzle velocity. I don’t find myself needing to go tweak it all the time to make it align with hits in the field.

Thanks again for sharing!

Cal

……”overlooked the importance of a temperature stable primer.” You guys just blew my mind! Also interesting that Varget did better at lower temps. While H4350 was better in the higher regions. This could determine a persons choice depending on their geographic location, as far as hunters go anyways. That is to say someone who shoots mainly in cooler climes, use Varget. Once again, my mind is like a sponge with your information.

Ha! That was Patrick’s idea, and when he mentioned that it blew my mind too. My gut tells me you wouldn’t see as much variance as you would in powders, but I definitely don’t know that. It’s funny how a question like that can bring to light some of the basic assumptions we make! I’ve definitely thought about that one a lot since I first heard him suggest it.

And I agree with the point on Varget being more stable at lower temperatures. Another reader made a comment about that, and honestly I hadn’t made note of that before you guys said something about it. It is an interesting point, and a compelling case for hunters to develop loads based on Varget. I personally hunt with a 7mm Rem Mag (aka God’s hunting cartridge 😉 ), so I wonder if H1000 or Retumbo exhibit similar properties. Ha! There is another test I may have to go out and shoot one day. This is certainly a rabbit hole! The more questions you try to answer, the more questions you find. But it’s a lot of fun. It feels like we’re still in the steam engine days of all this, and we’re our learning is just accelerating. It’s a fun ride to be on at this unique point in history.

Thanks,

Cal

I was glad to see that you qualified the results to the particular lots of powder used. These numbers will change from lot to lot for any given powder. In fact, from time to time we have seen an inversion of the powder temperature – muzzle velocity relationship for a particular lot of powder where the muzzle velocity actually decreased as the powder temperature increased.

Wow, Blaine. I could definitely see a change of rate between lots, but the muzzle velocity going down as temperatures go up is something I haven’t seen. The idea is bending my mind a little bit. Can you tell me a little more about the specifics of when you saw that?

Thanks,

Cal

Interesting Test. One thing I noticed is that even though IMR4166 didn’t had the smallest muzzle velocity per degree fahrenheit variance, it seems to have the most liniar characteristics. So maybe a interesting choice for those that actually correct for temperature, but don’t have a device as sophisticated as the mentioned Kestrel Elite meter. Liniarity is always woth something I guess.

A primer temperature sensitivity test would be interesting aswell.

And maybe annealing befor resizing could help a little to uniform neck tension, even on the first reloading. Maybe overkillt for “conventional” match ammo, but for those kind of tests… who nows.

Just a few thoughts.

I really enjoy and appreciate what you are doing here!

That is a great point, Martin! I hadn’t thought of that, but you’re absolutely right. There is some value to a powder have a predictable, linear change in muzzle velocity.

And you’re in luck. Bryan Litz actually did test the affects of annealing and neck tension in his new book, which will start shipping in just a couple weeks. I had the priveledge of getting to proofread that chapter, and it is VERY interesting. I can’t give anything away, but I will say that I was shocked by the results. I bet you will be too. He actually tests a lot of common handloading steps like that, and looks at what affect it has on the measurable consistency of the ammo. I found it VERY enlightening. You can pre-order that book at a discount for the next 2 weeks, then it’ll go back to full price. You can order it here: Modern Advancements in Long Range Shooting: Volume II

Thanks for sharing your thoughts, because I hadn’t even thought about the value of having a linear relationship. It’s an interesting view.

Thanks,

Cal

Thanks Cal, It’s already preordered and I’m really looking forward to beeing shocked! 😉 Happens to be perfectly timed, since I’m currently thinking about spending money on a more sophisticated annealing setup, and it would be awesome to make this decision based on proper data. Knowledge is power, they say…

You bet! I just bought an annealer, and seriously wish I would have read it before I made that purchase. Hold out man! Glad the timing worked out better for you than for me! 😉

Thanks,

Cal

Another thing that came to my mind, that kept me wondering since the introduction of the magnetospeed:

Wound’t magnetospeed readings be generally a bit highter, since it measures the relative speed between exiting bullet and recoiling rifle, and not the relative speed between bullet and “earth”?

So depending on the caliber, muzzle device, recoil management, rifle weight,.. shouldn’t there be some deviations?

I know there are some kind of recoil calculators, that would calculate recoil force and speed (I think), but I never played around with one to see if it’s actually in a magnitude range to cause a difference, also they don’t take recoil management and muzzle devices into consideration.

regards,

Martin

Ha! Interesting point, but I went back and looked at the data. As I mentioned in some other comments recently, I shot 5 different cartridges/loads over all 3 of those chronographs. In 3 of those cases the average muzzle velocity of the LabRadar was faster, in the other 2 the MagnetoSpeed was faster. The Oehler was 20-30 fps slower in all 5 cases.

I’m not sure if there would be significant variation with larger magnums or not. It’s an interesting question. Since it’s rigidly attached to the firearm, it’s plausible.

Thanks,

Cal

Cal,

If you do primers, try Sellier & Bellot primers (at least LR). A friend turned me on to them, and they took my SD down from low teens to low single digits in 6.5 Creedmoor. They are cheep and they seem to work – i’ll have more data after shooting them through the rest of the year.

Hey, David. I actually ran a test on my personal loads where I loaded a 60 rounds with the same exact load details, except 20 of them used Federal 210M primers, 20 used CCI BR-2 primers, and 20 used Sellier & Bellot LR primers. In my experiment, the Federal had the worse SD of 19 fps over the entire 20 round string. The Sellier & Bellot LR produced an SD of 15 fps, and the CCI BR-2 primers produced an SD of 10 fps. This was all before I bought a Prometheus Gen II Powder Scale, and now I’m consistently getting 4-6 fps SD’s using CCI BR-2 primers. It would be interesting to run through this again now that my charge weights are MUCH more uniform.

I two other OCD handloaders that I’m good friends with run through the same experiment. One of them ended up with the same order as me, and I think the other one (who was actually Patrick, the guy who did this powder test) said the Sellier & Bellot primers produced the lowest SD’s for him, but CCI was right behind them.

That was enlightening for me at least. I bet this can vary by the lot of primers you get … unfortunately. So I’m not sure how universal my results are. That’s why I never did a post about it. Really to reach any universal truth you’d need to test over several lots of each primer and I just don’t have the time to do that. It’s be another interesting experiment!

Thanks,

Cal

Thank you for another test.

I understand that this is vital information for first round hits, but the scenario I am more interested in is: what happens if you fire 6 shots (or more) in rapid succession, to walk your rifle in at a new zero distance, then chamber a round … maybe fiddle with the scope for some time … adjust your bipod … wait for the wind to die down, then shoot.

Will this exposure to a very hot chamber (supposedly a lot hotter than the ambient temperature) not throw out any chance you have of a hit? How fast does the heat from a hot chamber transfer to the kernels?

What are the temperature sensitivity, once you got your chamber ‘up to working temperature’?

That’s a great question, Kasper! In the barrel test I conducted recently, I measured chamber temperatures over a 20 round rapid-fire string (all fired within 1 minute) and a 50 round slow-fire string (fired over 20 minutes). The temperatures I recorded weren’t as high as you might think they would have been. Even on the rapid-fire test, the highest chamber temperature I found was 149° F. Now semi-automatics would likely get much higher, but this was all done for bolt-action rifles and 20 rounds per minute is a pretty quick rate of fire. So honestly, the range of temperatures you see in this powder test probably represent the extreme range of temperatures you’d experience in the situation you described. I’d imagine that even if you left the round in a chamber that started out at 149° F, the gun powder would likely never heat up more than the 140° F … because barrels start to cool fairly quickly.

So, this test really does provide everything you need for an answer. At this point, you’ve got me wondering myself … so let’s walk through it. Let’s say it’s 65° F the day of the match, and in one scenario you only close the bolt on a round for about a second before you send the shot … so there is essentially no heat transfer to the powder. In another scenario, you loaded the round in a really hot chamber and the powder was heated to 140° F. To answer your question about could it ruin any chance of a hit, let’s assume you are using one of the lesser performing powders in this test, IMR 4451. I opened up the Applied Ballistics Analytics software, and ran the numbers. I used the 6.5×47 Lapua muzzle velocities for the Berger 140gr Hybrid from our test, and even used the Custom Drag Curves for that bullet (which in my experience make the predicted ballistics align VERY closely to the real-world results). I’m not sure what target distance you shoot at, but we’ll assume an even 1000 yards to really make any variations in muzzle velocity stand out. Here are the results:

So that’s a difference in POI of 15″ at 1000 yards, just from leaving the round in the chamber for an extended period of time. But, like I mentioned before, I’m not sure you would be able to heat the powder all the way to 140° F based on the chamber temperatures I recorded in my recent test. But there are so many variables at play that it is at least plausible.

Now let’s run that same exact scenario for the muzzle velocities we got for the most temperature stable powder, H4350.

So in the same exact scenario, you’d only be off by 3″ at 1000 yards with H4350 instead of 15″ with IMR 4451! Now that really illustrates the power of using a temperature stable powder! Think about if you used a powder that was specifically formulated to be temperature stable like IMR 4350, one of the Reloader powders, or the hundreds of other kinds. You’d might be off by double that!

Thanks for asking the question, because it really drives the point home.

If you’re interested you can read all about the results I measured regarding barrel heat in Bryan Litz’s new book.

Thanks,

Cal

Great work Cal. Could you tell me if you had 100% powder burn in the 22″ barrel? Also was the speed based on the Lab radar and verified with Magnedo, or average of both.

I’m not sure if we had 100% powder burn in the 22″ barrel. My guess is most was burnt, but not all. Maybe 90%. Here is an interesting article I read recently on barrel length and a 6.5 Creedmoor, which has a very similar case capacity: http://rifleshooter.com/2016/02/6-5-creedmoor-effect-of-barrel-length-on-velocity-cutting-up-a-creedmoor/

According to that test, it looks like the powder was fully burned and muzzle velocity optimized at 24″ for the 6.5 Creedmoor with 142gr SMK bullets and H4350. That seems to fit my experience. You only give up about 34 fps going from a 24″ barrel to a 22″ … which is nothing in the grand scheme of things. It will have virtually no measurable impact on hit probability.

And the speed was averaged between the two chronographs. There is no way we could know for sure which one was right, so the safest bet was just to average them. They were very, very close … so it didn’t really matter much.

Thanks,

Cal

Quick typo, i think you forgot the word “per” in when giving general sensitivities

“Best Single Base Powders: 0.1-0.2 fps degree Fahrenheit”

But too the article, did you guys shoot the ammo while they were still in their temperature extremes, or let them settle down to ambient?

Great test! its cool to see how temperature affects these things. If you have time you should plug in the numbers you got into your monte carlo simulator. It would show the actual real world impact of being off by 1-2F or by not correcting for the temperature at all!

Ha! Adith, I appreciate your attention to detail. I can’t sneak anything past you! I got that typo updated.

Great question. We didn’t wait for it settle back down to ambient. They were shot at the extremes. That would have essentially be testing the effects of storing ammo at extreme temperatures, which I don’t think would have near as dramatic of an effect. But I don’t know that, so it’d be something else interesting to test!

I don’t think being off by 1-2 degrees would have any measurable impact on hit probability, but it’s more of the 25+ degree changes that may lead to a miss. The lesson here is to just not assume that the muzzle velocity you shot 60 degrees will be identical for 90 degrees. It just doesn’t work that way. But unfortunately, most people don’t know that and most ballistic calculators don’t help you account for this kind of variable. Think about all the dope cards you’ve seen printed out. Some are based on one set of environmentals, but there are some that are more advanced and vary that by DA. But how many vary the muzzle velocity by temperature? I’ve yet to see one. This just isn’t as well known as it probably should be (outside of pros or veteran shooters), but hopefully this will help educate more shooters.

Thanks,

Cal

How do i attach a pic?

I have an interestng BDC turret wrap design from my scandinavian friends and it spans from -20 to +20 for Lapua military sniper ammo any variation is staggering once you get past 500m or so.m

http://www.strelec.si/forum/attachment.php?aid=5108

Would have been nice to see Alliant Reloaders temp sensitive powders tested, otherwise not a bad article, didn’t expect there to be much of a differnce since the companies are both owned by the same people.

Agreed. I thought about that as I was writing part of the content. I mentioned that Alliant Reloader was likely much higher, but I wish we could have quantified that. Honestly, we just aren’t interested in that powder because of what we’ve experienced with it in terms of temperature sensitivity.

And IMR and Hodgdon are both owned by the same company, but H4350 and Varget are actually made by another company in Australia. For all I know, the IMR powders we tested were made in Romania … or the same factory in Australia. You certainly shouldn’t assume that something will be similar just because they’re owned by the same parent company. That’s a fallacy. For example, Freedom Group owns a ton of companies like Remington, Bushmaster, DPMS, Marlin, etc. But, just because a Remington M24 shoots sub-MOA doesn’t mean a Marlin lever action rifle will.

Thanks,

Cal

Having shoot RL17 in a tactical .284win over past 3 years and from 5°C – 30°C i can say its quite sensitive to temperature change , but suprisingly consistent in regards to SD and ES

I also used RL 15 in my 6.5×47 F class gun but only in 20-30°C where it proved far less temperamental than Vihtavouris N540 or N550

RL 17 is made by Nitrochemie and sold in Europe as Reload Swiss RS60

RL 15 is Norma 203B

I think its commonly known that RL15,17,22 and 25 are temperature sensitive. That being said I think the premise of this test was to test the most common powders used in the top 100 of PRS competitors. If you were to start bringing in other powders it would muddy up this data and someone would complain that his powder was not tested.

It will be interesting to see if any of the new RL powders start getting some notice and use. RL16,23 and 26 are supposed to be temperature stable.

That is exactly what we were trying to do here, and I couldn’t agree more. I do wonder how those newer powders would do, but I guess I’m skeptical in Alliant’s quality at this point. But, it’d be interesting to see the data!

Thanks,

Cal

Thanks for the testing, I use H-1000 a lot, I wonder if it is just as stable since it’s also a Hodgedon extreme powder. Great article

Hey, Dan. I’m wondering the same thing! I use a 7mm Rem Mag hunting (and some target shooting 1200-1760 yards), and have used both H1000 and Retumbo. My gut says they’re probably in the same ballpark as these powders, but I certainly don’t know that. I’ve been surprised before! I plan to test my lot of powders myself and see what I find. I probably won’t have time to do that until closer to hunting season, so you might test yours and see what you think.

Thanks,

Cal

Great work! Thanks for taking all the time and trouble to do objective testing.

Another excellent test on a topic that all of us have been interested in – keep up the GREAT work Cal!

I would be very useful to know the ES and SDEV of the rounds with each of the different powders. The tester basically used exactly the same powder weight for all 4 powders and although it was not stated, I would assumed that they were not centered on an accuracy node in all 4 situations. As most reloaders know, there are powder weights that produce both precision and low SDEV but also weights that produce one or the other. When ES/SDEV are not consistent, they tend to distort the average MV measured. Just wondered if this affected the results posted.

The other thing I would really like to see posted when I see a bar graph used to make a comparison is to see standard error bars. I worked in research for 30 years and we used these graphs to make our point all the time. What you never see are bar graphs without standard error bars because just a difference in the height of the bars does not in any way give the audience an idea of whether the difference is significant. What we find is when the bars have standard error bars and those bars do not overlap, there is a significant difference. If the bars overlap, there is no statistical significance regardless of the difference in average magnitude. I would really like to see you include this in your very well done studies.

You’re correct. The loads were not tuned to an accuracy node for the test rifle. Here’s what Patrick said in the article:

I agree that a load that produces the best SD’s doesn’t necessarily mean it will produce the best groups, and vice versa. I think one is more related to case design, powder, and internal ballistics, and the other is related to barrel harmonics and finding that “accuracy node.” In long-range shooting, I put more weight on low SD’s and good group size (prefer below 1/2 MOA), over super-tiny group size and higher SD’s. (Honestly, with the Prometheus getting low SD’s is pretty easy with most powders.) Patrick didn’t spend time trying to tune a load, because really we were trying to hold the load as the fixed variable and the temperature as the independent variable. I’d bet the results would look very similar in terms of muzzle velocity spread, even if you tuned each load. The groups might look different, but I just bet the muzzle velocity spread at different temperatures might not vary much. So I’m not interested in spending time digging deeper into it … But I’ve certainly been surprised before! If you’d like to run through that, I’d be very interested to hear what you find!

And I totally agree about the standard error bars. I personally like stats and understand them, and standard error is such a great thing to know on tests like this. In fact, when I was at the Applied Ballistics Seminar back in March, I asked Bryan what the standard error was for some of his test results. That one number can tell you a lot about the strength of the conclusions you can draw from a set of results. But 99% of my readers don’t know what “standard error” is, so those little bars would only confuse them. I try really hard to make this approachable and applicable by the average shooter or even beginners, even though I seem to have attracted really educated shooters (obviously you’re one of those). So I’m always trying to balance keeping it simple and providing more detail for those on the advanced track. I say all that to just help you understand that I agree that is valuable, but I just want you to understand my goal of helping the average shooter from getting tangled up in the details. They’re my primary audience, and I try to shape the content for them, and maybe add a couple nuggets in there for the more advanced crowd (like in this post, I pointed out the non-linear relationship and brought up the question about primer stability). While I do try to use sound testing methods that would satisfy most professional researchers, ultimately, I’m not trying to write whitepapers that can only be understood by the engineers among us. That’s fun for me, but it just limits the value you add to the shooting community as a whole. So I always try to present the results in a way even a novice could understand. Hope that makes sense. Sorry for the long-winded response. Your point is a good one, and you obviously put thought into it … so I just wanted to try to help you understand my view when I’m writing this kind of content.

Thanks,

Cal

Cal – I understand where you are coming from when you say make your articles “approachable”. I am a big fan of this style of writing as I have always told my students that if you lose your audience after 5 minutes of presentation, it does not matter if your work is Nobel Laureate quality material, if no one understands it, it is a waste.

However, you have to understand that there is a limit to the degree of simplification that one should go to. By not putting in the simplest of statistics that shows what you guys have done is meaningful/significant, the data you present becomes unfortunately meaningless – basically a bit of “trust me” but I am not going to show you the data.

Prove unfortunately is not descriptive but data driven and my suggestion again is for you to put in the bare minimum which is the error bars. It will certainly go over the head of those who are not interested, but available to anyone with a remote statistical background trying to figure out if you guys know what you are doing.

I do get what you’re saying, and really don’t want to be argumentative … but I guess we just disagree on the right balance between simplicity and complexity. Luckily, I’m the author here and the one that puts so much time into all this stuff, so we’ll go with my vision for the content.

Thanks,

Cal

JLow:

Do you mean SD with respect to the group center? If so that is one measure of precision. Or do you mean SD with respect to the aim point? In the new definition accuracy = trueness + precision. Trueness is the offset of the group center from the aim point. For shooting a better term might be centeredness.

Very good point about error bars.

Rick – I mean error bars for the key data. For example, in the “Muzzle Velocity Variance from 25 degree F to 140 degree F” chart, For instance 24 fps change in muzzle velocity for H5350 vs. 68 fps for IMR 4451 looks different but if the error bar for the rounds tested shows a range of change which is overlapping for the two powders, then it is just noise and not real difference.

So in layman’s term, let’s look at two situations:

1) Let’s say the average change for H4350 was 25 fps but this was the average number from say testing 10 rounds and of those ten rounds half shows a 68 fps change but the other half only have a few fps change… At the same time for IMR 4451, the average change was 68 fps but half the rounds only show a change of 25 fps and that average number was only 68 fps because the other 5 had big change numbers say over 100 fps. With data like this, the error bars will overlap and that tells the reader that there is a lot of noise in the test and the average number cannot be use to make the case that the variance of the two powders are actually different.

2) In another instance, let’s say every one of the H4350 rounds shows exactly 25 fps change and every one of the IMR 4451 rounds shows a 68 fps change – the error bars would be super tight and they would never overlap. This tells the reader that the data is super good and very believable.

This is why just looking at the magnitude of the difference has to be taken with a huge grain of salt unless the stats are there to support the conclusion that they are different and standard error bars describes it much better than my long winded description.

jlow:

Sorry for not reading your post more carefully. Your comments, as the Brits would say, are spot on. For my own data sets I generate a histogram in addition to calculating the mean and SD. Histograms complement error bars.

We are all thankful to Cal and his colleagues for the time, effort and money to expend in doing careful experimentation. And Cal presents the results excellently at his desired technical level. If I were to make a suggestion, it would be to establish an archive containing the full description of the experiments and the results. Then anyone wishing to delve deeper, such as their own statistical analysis, could do so. Maybe if enough people contributed Cal could hire someone to do the archiving.

You do realize that when you change the temperature of the bullet by that extreme of an mount that the physical size of the bullet actually changes. It’s no wonder the velocities were different if the diameter of the bullet is .003″ different at those two temperatures. To even get somewhat accurate results of this theory the actual rifle would have to be heated and cooled at the same time as the bullets. Freezing a bullet shrinks it significantly. Heating it that much expands it significantly also. Even with friction Heating from the barrel the pressure between the two would be significantly different. A “fatter” bullet going through the same barrel as a “skinnier” bullet is obviously going to move at different speeds… Powder asside.

That’s an interesting point, Steve. I haven’t ever heard someone mention that before. I don’t claim to be an expert in metallurgy, so that could certainly be the case. And I readily admit that like any test, this wasn’t perfect. I heard a data analyst say one time “Every model is wrong, but some are helpful.” That seems to be true here too. Hopefully you still found the results helpful.

Thanks,

Cal

Cal:

Some models may be flat-out wrong but it is better to say all models are an approximation to reality. And that includes the fundamental laws of physics.

However, in an engineering sense the question is whether the model/law is a good enough approximation. Is it fit-for-purpose? Does it generate predictions that are sufficiently accurate. For example, the full 6 DOF system of equations for the motion of a rotating, symmetrical ballistic projectile is a better approximation than the 3 DOF system of equations but the 3 DOF system is sufficiently accurate for many trajectory calculations.

An interesting point since the bullet would have a greater diameter at higher temperature due to thermal expansion. But, as always, the crucial question is the magnitude of the effect, Would it change the muzzle velocity by 100 fps, 10 fps, 1 fps, 0.1 fps or 0.01 fps? Would it change the group precision at 100 yards at all? Would it change the SD of the muzzle velocity at all?

Go to the range with a given rifle, ammunition, sighting system and platform and determine the group precision at 100 yards, mean muzzle velocity and muzzle velocity SD for a given ambient temperature. Then all individual effects such as effect of temperature on powder and any effect due to thermal expansion or change in physical properties are “included” in your measurements. This is the classic engineering approach but degree pf applicability of results to other rifle-ammo-sight-platform systems is probably little known at best.

Measuring individual effects certainly is intellectually interesting. Knowing individual effect may have a practical value in that more likely to know degree of applicability to other rifle-ammo-sight-platform systems.

Re. jlow & Rick

I would think the extreme temperatures and pressures of bullet obturation pretty much homogenize the bullets metallurgy diameter towards their original production standards.

The self funding of Cal’s research and Trump’s candidacy seem to both be coming to their limits. Cal has given us tremendously from his life’s most precious asset…his time.

Thanx,

CR

Cal:

Did I miss any observation on how temperature affected the SD of the muzzle velocities? That is, for a given powder was the SD of the muzzle velocities the same at the temperatures of the experiment? Also did you measure the precision of the group since temperature affects many physical properties of steel?

Rick

Rick, I don’t have that data. I don’t know if Patrick still has record of the SD’s or group sizes. I’ll check with him and see.

Thanks,

Cal

Hi Rick, if the load Started out with a single digit SD then it held true. H4350 and Varget both held single digits throughout the test. Groups were not recorded as I was trying to get the shots off as my timer went off immediately so that a “hot chamber” or “this, that, and the other” did not mess up the results.

Thanks, Patrick

Patrick:

First thank you for your time and expertise in doing the experiment and secondly in answering my question.

At least for the powders tested the variation of the muzzle velocity SD with temperature was only a few fps. Thus not variable for most, if not all purposes. Always good to turn a potential variable into a constant.

Completely understand your methodology did not permit shooting for precision.

Best, Rick

Thanks again Cal !

For the awesome work, I appreciate all your awesome efforts in explaining all your posts out so us beginners can clearly understand! ….keep up the great work

You bet, Heber! I really appreciate the compliment about it being easy to understand. That is one of my biggest goals in my writing, and it’s a struggle at times … but it’s good to hear it was presented in a way that was easy to digest. Tells me I’m headed in the right direction.

Thanks,

Cal

Thank you, Sir. Following the lead of those who are more experienced than me has paid off. I use H4350 exclusively and I need all the help I can get.

Cal:

Temperature affects:

1 – Density of air

2 – Ammunition – burn rate of powder and diameter of bullet

3 – Barrel – barrel density, length and bore diameter from thermal expansion/contraction. In addition to density, temperature would also affect the barrel bulk and shear moduli and together these three factors determine the possible barrel harmonics. Which harmonics are excited depends on ammunition.

The effect of temperature on barrel and bullet diameters would be an interaction effect between rifle and ammunition.

I read that bench rest competitors, if possible, load their ammunition on the day of the match. I can imagine them loading several sets of ammunition for different temperatures in order to achieve the 0.1 MOA precision needed to win. Knowing their methodology in detail would be most interesting.

Interesting idea, but I’m not sure it has a measurable impact at the temperatures we’re talking about. Bolt action barrels just don’t get near as hot as other barrels. I measured them in my barrel test, and it surprised me that they didn’t get hotter than they do. I don’t think I recorded any temperatures above about 180 degrees F. Is this documented in any peer-reviewed place you can point to? You’re a sharp guy, but I always try to provide 3rd party support in my posts (like in this one I referenced Litz and the research on Kestrel’s website). Where can I read more about the barrel’s role in this?

Thanks,

Cal

Cal:

From from “Accuracy and Precision For Long Range Shooting”/ p 86.

“Ir’s not uncommon for rifles to hit different POI based on the velocity of the load due to harmonics, which are unpredictable” But no comment on magnitude of the effect as a function of temperature.

Another temperature effect from “Accuracy and Precision For Long Range Shooting”/ p 86 “Temperature can also affect a rifle zero due to bedding, receiver and scope being made of different material and having different rates of thermal expansion. This would affected the centeredness of the group.Again no mention of magnitude of the effect as a function of temperature.

As to benchresters handloading on day of meet it stuck in my mind when I read the article but have no idea of the source.

I know references that calculate barrel harmonics/vibrations and references that present the temperature dependence of the elastic constants of steel but none that explicitly calculate the change of barrel harmonics/vibrations as a function of temperature because of effect on elastic constants. A project.

Benchresters do load on the range and match but in regards to powder charges the are not awfully relevant ,most use volumetirc Harrells BR powder measure i would be suprised if they charge better than +- 0.2grain charges . On the other hand the brass they use is fully worked over and downselected ,they might use only 10 cases from a 100case box and run the same 10 cases till the barrel is toast.

In 100-200y distances that is not that much of a factor.

Very interesting. I’m not a benchrest guy, so it’s good to know what those guys are doing. That seems to fit what I’ve heard, too. It’s an interesting little sport! There are probably a lot of lessons we could learn from that side of the precision rifle world.

Thanks for sharing,

Cal

Cal,

Great job as usual. This is valuable information.

A quick note on a comment you made about H4350 and Varget. The rifle used had a 22″ barrel and this is why the velocities with Varget were higher than that with H4350. Varget has the optimal burn rate for that barrel length. H4350 is better with 24-26″ barrel lengths because it is slightly slower and is in turn a better powder for the longer barrel. This is something that is often overlooked especially with short barreled 308’s and can be said for most any cartridge. I have friends that scratch their heads when my 20″ 308 using H4895 gives the same velocity as their 24″ 308’s using Varget or IMR4064. Its all about burn rate.

Thanks, R700. Sounds like as good of an explanation as I’ve heard. Certainly fits my experience. On a side note, I do use H4350 in my 22″ 6.5 Creedmoor and I love the results I’m getting. But I don’t doubt that I might be able to squeeze a little more muzzle velocity from another powder. I know lots of guys chase that last little bit of muzzle velocity, but those 25 or 50 fps bumps have virtually no impact on hit probability when it comes to long range targets. (Check it out: How Much Does Muzzle Velocity Matter?) A temperature stable powder with low SD’s is just more important to me, and H4350 delivers on those fronts. Never measured H4895, so it might do that as well. Interesting point for sure.

Thanks,

Cal

I too run H4350 – 44 grains in my 22″ barreled 6.5CM with a 130 VLD. I don’t get a full burn but close enough. I am at about 103% fill ratio and ES and SD is excellent at 2780 fps.

Thanks for such a great website. it is nice to have unbiased fact based data to review. I can’t wait to read your barrel evaluation. My son has a 300WM on the back burner until we read the barrel comparison in BL’s book. Was going to do a PR barrel but will wait until we see the results.

Why in the world are you running loads that don’t have a complete burn…?