When the 7mm Remington Magnum was originally released, it was met with overwhelming demand. Every rifle manufacturer rushed to offer rifles chambered for the new cartridge, and in the rush some of the chamber dimensions varied slightly from different manufacturers. This variation in the 7mm Rem Mag chamber dimensions has carried on to today, and there is still more differences in the chamber dimensions than for virtually any other rifle cartridge.

What’s a chamber print?

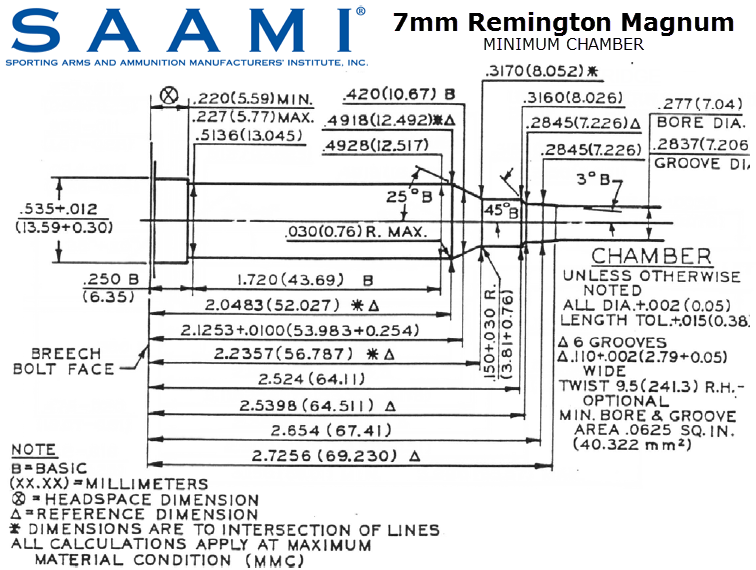

A “chamber print” is an illustration of the chamber reamer used to cut a rifle’s chamber. It contains all of the key dimensions related to the size and shape of chambers cut with that specific reamer. You can find a lot of helpful numbers off this diagram that are useful for precision handloading including neck diameter, headspace (i.e. base to cone length), base diameter, shoulder diameter, case length, etc. If you wanted to created a completely new “wildcat” cartridge, all you need to do is create a chamber print like the ones shown here and send it off to someone like Pacific Tool. They’ll make a reamer that matches the dimensions you specified and your ready to chamber your first rifle with it.

Standard 7mm Rem Mag Chambers

The diagram below contains the minimum chamber dimensions published by SAAMI for a standard 7mm Remington Magnum.

My “Match” 7mm Rem Mag Chamber Print

This is the chamber print used to cut my custom 7mm Rem Mag rifle made by West Texas Ordnance. There are a few customizations with this chamber to improve performance:

- It has a tighter, “match-style” neck (0.312” diameter) than most factory rifles (SAAMI spec is 0.317”). This tighter neck is designed to ensure the cartridge is more precisely aligned with the bore, but that may mean you have problems chambering a round if you don’t trim the case necks on your handloads. If you shoot factory ammo, you may have problems with the tighter neck in a “match” chamber. You typically want to ensure the neck of the ammo you are shooting has at least 0.004” of clearance to prevent potential chambering issues (e.g. with a chamber neck diameter of 0.312” you should target the neck diameter of loaded ammo to be 0.308” or less).

- The freebore length is .023″ longer than the SAAMI spec, which allows slightly more case capacity while still allowing ample space for a VLD bullet to feed from a magazine box.

- The lead angle was changed from a SAAMI spec 3 degree angle to a 1 degree minus 30 minute angle. This matches the VLD bullet shape better, and allows the bullet an easier start into the rifling. I’m not sure how the 1 degree -30 angle was originally decided upon (far brighter minds than mine designed it), but it has been consistently proven to provide better performance with VLD bullets across all bore diameters.

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

One comment

Pingback: Neck turning and chamber sizing