Creighton Audette came up with a method for developing precision rifle handloads that has been referred to by many names:

- Incremental Load Development Method (ILDM)

- The Ladder Test

- 20 Round String Method

Unfortunately many of Audette’s original articles aren’t very accessible, so I wanted to provide a few resources that help flesh out the method to load development he proposed. I recently tried it out, and although at first I admit I was a little skeptical … after seeing the real world results and some critical thinking about what we are really trying to uncover when doing load development, his method seems to make a lot of sense. At the very least it provides a great starting point for testing a particular bullet, powder, primer, case combination, and will likely save you some time, frustration, and barrel wear.

- Brief Overview of Audette’s Incremental Load Development Method (Excerpt from Precision Shooting Reloading Guide, Published 1998)

- Complete Deep-Dive Into Method & The Science Behind Why It Works by Randolph Constantine (Published in Precision Shooting Annual, 1997)

My Ladder Test Results

I was trying to develop an accurate load for my Rock River LAR-15 Varmint firing Berger’s 22 Caliber 77gr Match OTM Tactical bullet (relatively high BC for 22 caliber, G1 = 0.376, G7 = 0.192). I typically favor with Hodgdon’s Extreme Series powders, because of their proven consistency and insensitivity to extreme temperatures. So in that line-up, both Varget and H4895 were good candidates. Looking through reloading manuals and online sources, I found a wide variety of min/max loads for similar bullets like the 77gr Sierra MatchKing and Hornady’s 75gr A-Max, and eventually came up with these as my starting/max loads:

Min/Max Loads for Naked Bullets

| Powder | Starting Load (gr) | Max Load (gr) |

|---|---|---|

| Varget | 22.2 | 23.9 |

| H4895 | 22.0 | 23.6 |

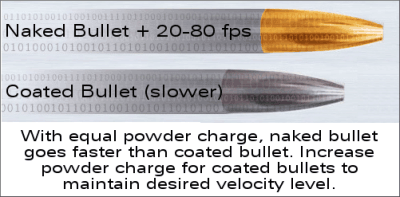

However, that was for “naked” bullets, and I was also planning to coat the bullets using David Tubb’s Precision Blended Boron Nitride (HBN) to further increase BC, reduce barrel wear and fouling, improve the first/cold shot grouping with subsequent shots, and hopefully improve accuracy as well. One of the side-effects of applying a bullet coating like HBN or moly is that because it reduces bullet friction in the barrel, it will reduce chamber pressure and muzzle velocity. To offset that effect, you need to increase your powder charge to get back up to the muzzle velocity of naked bullets. One cool side effect of this exchange is that chamber pressure will still be lower than it was with naked bullets, even when you increase the powder charge enough to attain the old muzzle velocity. For more on this topic, see http://www.6mmbr.com/bulletcoating.html or http://www.6mmbr.com/normamoly.html.

In Norma’s testing, they typically saw a decrease in pressure by 3-5% for coating bullets over naked bullets (depending on cartridge, bullet, & powder). To offset that affect I decided to increase my max load around 104% of the naked bullet max I found in reloading manuals and keep a very close eye out for signs of excessive pressure.

In Norma’s testing, they typically saw a decrease in pressure by 3-5% for coating bullets over naked bullets (depending on cartridge, bullet, & powder). To offset that affect I decided to increase my max load around 104% of the naked bullet max I found in reloading manuals and keep a very close eye out for signs of excessive pressure.

Adjusted Min/Max Loads for Coated Bullets

| Powder | Starting Load (gr) | Typical “Naked” Max Load (gr) | ~104% of Max Load (gr) |

|---|---|---|---|

| Varget | 22.2 | 23.9 | 25.0 |

| H4895 | 22.0 | 23.6 | 24.8 |

Targeting Audette’s suggested 2 grain increments, the spreads between starting and max loads allowed me to load 15 rounds of each powder. This didn’t get me the “20 Round String” Audette suggested, but with such a small cartridge like the 223 Remington that would be difficult to do since there is such a narrow window between the starting and max loads recommended in reloading manuals. I also loaded an additional 5 rounds of each with the starting load to use as foulers, since I planned to start each string with a clean barrel.

I used a Competition Electronics ProChrono Digital Chronograph, which is accurate to +/- 1% of the measured velocity. Here are the recorded velocities of each load for both Varget & H4895 (10’ from the muzzle):

The target below (which was set at 200 yards) shows the bullet impacts for the Varget test rounds. Although I tried to find a windless morning, those are extremely rare in West Texas … so I did have horizontal drift because of the wind. One key to the Audette method is to use the exact same point of aim each time without making any adjustments. You can see that the points of impact correlate to the recorded muzzle velocities, and the tighter groups relate to the flatter portions of the velocity chart. (Note: Where they don’t match, you could likely blame my shooting.)

The H4895 target was erratic, just like you would likely expect from its velocity chart. It was even difficult to keep track of which shot was which because one shot would be up, then the next down … just like the velocity chart showed. This led me to eliminate it as a powder choice for that bullet. It simply indicated that with that bullet, primer, case combination … the powder didn’t compliment the natural harmonics of the barrel. It doesn’t necessarily mean Varget is more consistent in all cases, it just was for that combinations of components in that particular rifle.

As a result of this test, I’ve discovered two ranges of Varget powder weight that show very little sensitivity to minor changes in charge weight and/or pressure. At this point I plan to do more detailed testing within those specific ranges by loading 7 shot groups in 2 grain increments and testing how they group at 300 yards. Want to know why I’m going with 7 shot groups? Check out this great article: Statistics, Shooting and the Myth of the Three Shot Group.

Alternatives to Audette’s Ladder Test

A drawback of the Audette Method is that EVERY shot is figured into the “ladder”. If your rifle is prone to vertical dispersion (due to poor bedding, stock flexibility, poor quality optics, etc.) you may never be able to find the sweet spot based on any process that evaluates individual shots. Simply stated, the normal dispersion of rifles that are less than benchrest quality will give false indications and overshadow any meaningful results. With benchrest quality rifles (Creighton Audette’s first love), the Ladder Method works extremely well. But it can be error prone for sporters and other less precise rifles. The use of a chronograph can help, but ultimately the ability to see how the bullets group on the target is also critically important.

There are a few alternatives to conventional Ladder Test developed by Creighton Audette that was presented here. A populate one is Dan Newberry’s Optimal Charge Weight (OCW) Method, which some claim is an improved and less error prone way to perform load development. Here are a few useful links to learn more about it:

Who is Creighton Audette?

Creighton Audette did as much for the precision shooting community than possibly any other figure in history. His engineering background and objective, data-driven approach gave new insight and helped bring clarity to this emerging field that is often clouded with strong opinions, myths, and gut feelings. Audette (now deceased) has been referred to by people who worked with him as “the best engineer that ever worked at Frankford Arsenal”. He shot on the US Palma Team, and won multiple National Matches at Camp Perry. Many of his articles were published in American Rifleman and Precision Shooting magazines, and are still considered to be the most advanced and accepted methods in the field. One of my favorite quotes about him is “he had more intellect in two of his nose hairs about rifles, shooting, and engineering than probably the entire shooting community today!” He was truly a pioneer in precision shooting.

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

Cal,

Creighton didn’t always get the point of his own testing. Its NOT about velocity nodes, its’s about getting the bullet to exit the barrel during the time when it is rising to its maximum vertical, so that slower bullets exit the barrel later (higher pointing barrel), and faster bullets exit sooner (lower pointing barrel), thus self negating velocity variation. I recently ran across an article Audette wrote at White Oak Barrels. In that article he discusses this in a way that makes me think the information I have on my web site comes from a later point in his thinking. I willl be adding the White Oak article to my source material soon.

https://www.whiteoakarmament.com/pub/media/blog/It_Aint_necessarily_so_2.pdf?redirect_mongo_id=6797eaab62194c9aac6eebdc&utm_source=Springbot&utm_medium=Email&utm_campaign=6797eaab62194c9aac6eebdb

https://SnellsNotebook.us for my part.

Please don’t hesitate to contact me if you have questions.

Hey, John. I appreciate you sharing your thoughts. I’ve definitely heard the theory your referring to, about barrel timing and “positive compensation” where slower bullets exiting at the top and faster at a lower point. While that makes sense from a high-level, I’m not sure that is actually possible. Barrel vibration is an extremely complex topic, but they don’t move as simply as you are presenting. A barrel actually vibrates in several different modes and frequencies at the same time, so “timing” a bullet to exit at the exit muzzle position we’d like might be more than wishful thinking.

To learn more about barrel vibration, I’d highly recommend reading Chapter 4 of Rifle Accuracy Facts by Dr. Harold Vaughn. The book is no longer in print, but you can find several PDF version of it floating around the internet. Dr. Harold Vaughn is undeniably one of the greatest research scientists of the past century, and he explains how a rifle barrel moves under recoil in great detail and even measures it for several different types of barrels.

The guys from Applied Ballistics thoroughly tested the Audette Ladder Test and published their findings in Modern Advancements in Long Range Shooting Volume III. It’s the most detailed study of that I’ve ever seen, and their conclusion was this:

I won’t share the whole thing, but that is part of their takeaway from a lot of very rigorous research on the ladder method. I’d suggest picking up the book and reading the whole thing. You sound like an intelligent guy, so I’d bet it would be right up your alley!

Thanks,

Cal

Cal,

Thanks for the reply. I have Dr. Vaughn’s book on my self and I’ve read it cover to cover several times. I haven’t seen Brian’s #III (yet).

When I retired (2013) there was little to no information that I could find to trust in the public space about how to develop accurate loads, I didn’t want the same-old-same-old load a bunch and shoot it approach because I was pretty sure that wasn’t going to advance the art and science one bit. Neither did the literal tons of gun writers (mostly worthless) opinions on the subject, and loading manuals only give you safety data, and when they do give accuracy information it nearly always is for a specific rifle. My question “How do I apply that to crafting my own high accuracy ammo?” kept going un-answered.

Varmint Al (https://www.varmintal.com/aengr.htm) did a Finite Element Analysis that caught my attention at the time, as I was learning what I needed to know to begin my retirement project of building truly accurate rifle systems.

When I published my findings in https://SnellsNotebook.us I asked Al if I could use his material, and to please verify what I published. I’ve used material from Al’s analysis together with US Army Ballistics Lab (Aberdeen) as well as my own personal testing using .308, 6.5 Creedmoor, 5.56 NATO and .204 Ruger cartridges.

I have to reiterate that the Audette Test has nothing really to do with velocity (directly), nor anything other than where the barrel is pointed at the moment the bullet exits. My method of development is thus:

Using QuickLoad enter values for case dimensions, bullet dimensions, barrel length etc. Measure Case Capacity of Water (average of 20 samples typically), then calibrate Ba (Burning Rate Factor) by adjusting it so that Measured and Predicted MV are in agreement. From this adjust Charge Weight until you reach either 100% fill or PMax, and set this as the Maximum Charge Weight to test. Then adjust Charge Weight until Filling (Loading Ratio) is 90% – This is the starting charge weight. Divide the difference into 10 charge steps to load for testing.

NOTE: Quick Load analysis is only to get into a viable range quickly with a simulation.

Load one round at each charge weight. Seat the bullet as far out as you are willing to go (Max magazine or zero to negative jump).

At 200 or 300 yards fire each test charge at the same target using the same hold (Ignore small wind changes – it won’t affect the test results. If there are large wind changes, shoot another day.)

Mark each impact with the charge.

Look for consecutive charges that impact at the same elevation. Ignore horizontal spread. Sometimes these will group, sometimes they won’t, but they all share a gravitational ballistic curve and they all exited the barrel when it was approaching its maximum excursion in whatever direction with whatever other vibrations are significant.

Lest you think that barrel pointing is insignificant, please look at what Varmint Al published about a barrel tuner he investigated (also available on my web site).

For a given cartridge, bullet weight, shape, powder, primer, and seating depth – the average of those charges selected in the step above will be a good choice to further refine by adjusting seating depth.

Because you started with the bullet as close to the lands as possible, all subsequent seating depth changes will be to shorter COAL.

To test/adjust seating depth, I start with 3 rounds at each test depth to try to quickly locate a depth that significantly reduces group size. In conventional cartridges I use 0.010″ steps up to 0.050 initially. Usually this quickly reveals a range to investigate with smaller steps, and costs 15 rounds. In the case of my .308 and .204 this test program resulted in rifle/ammunition that consistently shoots into 0.3 MOA. In my 5.56 I have not been successful in achieving accuracy under 0.75 MOA (and that with only one ‘varmint’ load). The 6.5 Creedmoor ended up ‘locating’ the exact powder/charge/bullet combination that was the ‘favorite” of PRS at the time. In my Ruger Precision it shoots into 0.5 MOA reliably. I believe the problem with the 5.56 NATO is that I’m using AR15 style rifles. It has put me ‘behind’ by a couple of years, trying everything I can think of to make a MIL-SPEC (or better) rifle shoot like my bolt guns. This year I finally got around to adding a 5.56 NATO bolt action to test that theory.

In some cartridges, such as 6.5 Creedmoor (and possibly most of the new ARC style cartridges), the best seating depth may be 0.100 or more jump, and if you are loosing the throat to erosion necessary to maintain accuracy over the number of shots in a match.

Thanks for listening.

John

VERY interesting, John. That is different than what I thought you were saying originally. That actually sounds like a great process, at least based on what I have read over the years.

I think you’re spot on with the seating depth portion, too. I have started using longer jumps on my handloads ever since I combed through the mountain of data that Mark Gordon from Short Action Customs provided me with, which I published a few years ago. It’s very interesting, if you hadn’t seen it already: Bullet Jump: Is Less Always Better? The conclusion there is similar to what you mentioned, so it sounds like maybe you had.

It is interesting to see when independent load development efforts land on a very similar load, which sounds like what you experienced with the 6.5 Creedmoor. That shouldn’t be surprising, but it does give a little confidence boost to the repeatability of development process when you see that. I’ve noticed that a few times, so often I start with a load that is similar to what the pros said they use and then just test seating depth around those charge weights. I can typically find something that is great very quickly. It’s taking a shortcut, but it seems to have been effective for me. That’s especially helpful if there were several guys who were all using a similar load for the same weight bullet from the same cartridge. If lots of guys are having success with it, there is probably something consistent about it.

I appreciate you sharing! While we all love shooting tiny groups, there is absolutely something satisfying when you can wrangle in a load that is fine-tuned for a rifle! 😉

Thanks,

Cal

You are correct, I found the long jump 6.5 Creedmoor at about the same time you reported it. It was because the 143 ELDx wasn’t responding to any short jump changes. It shot into about 3/4 MOA all the time. At that point I started in on milk jugs at 1,000 yds and got all wrapped up in having fun with it. At some point I thought it was worth running a camera down the bore and I found that the neck to PMax was severely fire cracked. I remeasured the chamber and found the bullet contact point (zero jump) had moved forward a shocking distance, but the rifle still shot about the same. I checked my .204 Ruger barrel (still mostly pristine at a couple thousand shots fired). In this rifle, I favor a heavy 40 grain Berger that was very responsive to seating depth tuning at short jump. Just for a test, I reseated a few of my ‘standard load’ to jumps on the order of 0.125 and found that they shot into about 1/2-3/4 MOA. At the same time factory loads were at about 1 MOA. Fortunately, my short jump loads still cut those group sizes about in half, The knowledge that a long jump could work helped get 3 MOA 5.56 NATO AR loads down to around 1 MOA because magazine length restrictions made it impossible to use short jumps. I find that long jump loads are far less sensitive to tuning.

It was about this time I became aware that 5.56 NATO ammo often exhibit one or two episodes of the bullet coming to a complete stop between primer detonation and PMAX (ref Aberdeen Proving Ground notes in my notebook) long jump loads have higher fill rates because bullet base occupies more volume. Solid powder column can transmit primer shockwave to base of bullet mor efficiently than loose powder, sometimes knocking the bullet into the rifling (zero jump!) volume expands while pressure has yet to achieve sufficient strength to engrave the bullet (the whole firing process restarts with a much larger volume). I believe this explains how long jump loads work, and why fine adjustments to long seating depth have little effect on group size.

Thanks for giving me a bit of time and space to blab!

John

https://SnellsNotebook.us