I wanted to create a portable reloading press stand that I could mount my full-size RCBS Rockchucker Press or smaller RCBS Partner Press to. The plans I came up with were simple to build, used easy to find materials, and the finished product has worked exactly like I was hoping. The stand is very strong and stiff, which is critical when designing a reloading press mount. It is ergonomic and natural to use on either a table top or a work bench surface. I just use one or two Irwin Quick-Grip Clamps to hold it securely to the surface. The stand has “window cutouts” at the bottom of the sides and back of the press, which allow you to slide in a clamp jaw.

When making mine, I walked around the Lowe’s (a local hardware store) looking for thick, quality pieces of wood to use for this and discovered stair treads are typically very thick (a full 1″), made from tough woods, high quality, and very affordable. I was able to cut all of the wooden pieces I needed from a single, $19 red oak stair tread. The dimensions of stair tread I used were 36″ long, 11.5″ deep, and 1″ thick (unlike most lumber these were actual measured dimensions). The stair tread I bought had a rounded lip on one side, but it really doesn’t matter if it does or doesn’t if you simply cut from the flat side like shown below.

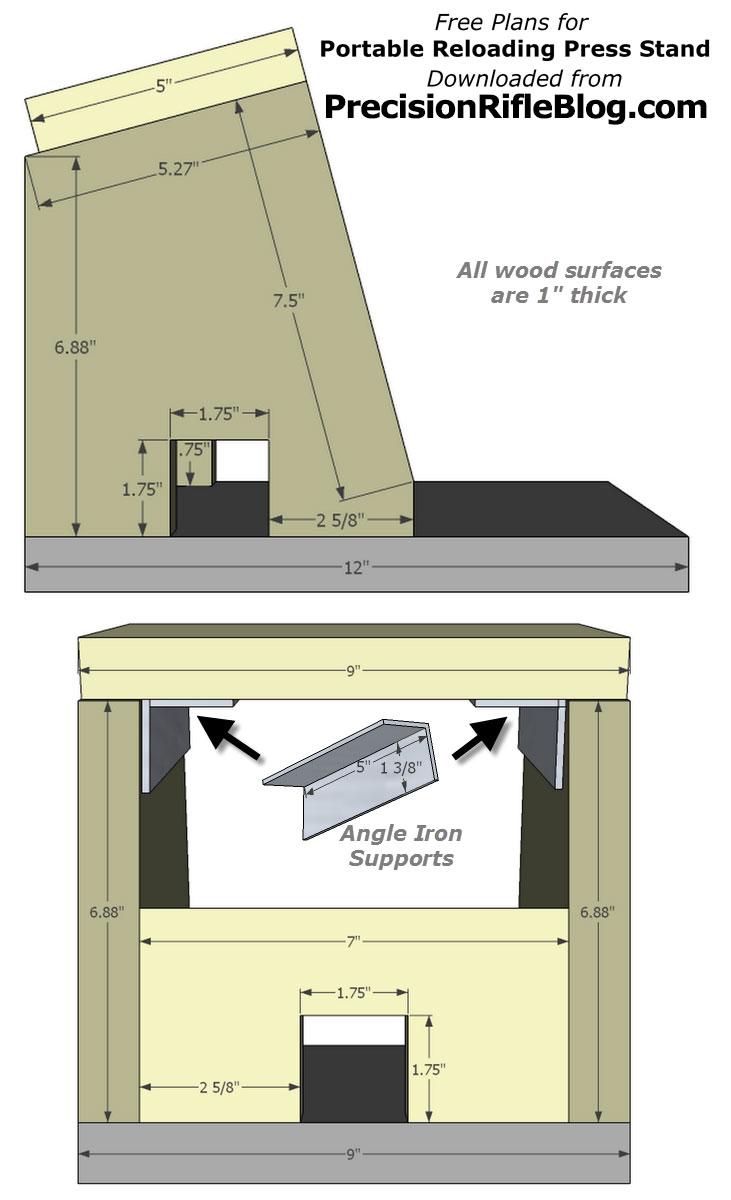

The sides are the most complex part, because I wanted the top plate to be angle slightly backwards. This makes it more ergonomic and natural to use the press when it is just sitting on a table top or work bench, and also allowed the top plate to be slightly shorter and still give the press adequate clearance for a full lever pull/ram stroke. Here is a more detailed cutout diagram for the sides:

While designing the reloading press stand, I made sure it would accomodate RCBS’s full-size Rockchucker Press, as well as their smaller and more portable Partner Press. You would just vary the mounting template you used to drill the holes on the top plate of the stand to accomodate the Rockchucker, Partner Press, or likely any of the other popular reloading presses out there. Click on the drawing below for a printable mounting template for RCBS reloading presses, or view my post that includes the full list of dimensions for RCBS reloading presses.

Here is the finished product. You can see I used bolts to connect the angle iron with the top plate and sides. In addition to the parts shown, I also attached 2 Simpson Strong Ties on each side of the press for added strength. This portable reloading press stand is built like a tank and I’m sure will last a lot longer than I will.

Building for Other (Non-RCBS) Presses

These plans were designed to accomodate an RCBS press, but if you are planning to use other types of presses you may need to vary the height of sides to ensure you have adequate clearance for a full stroke. Don’t worry, it is easy to measure. You can see in the photo below the RCBS Rockchucker Press requires around 8.5″ of depth for a full stroke. If your ram has a deeper stroke than that, just extend the sides by whatever additional depth you need. For example, if your press requires 10″ of clearance, that’s a difference of 1.5″ … so just make both sides 1.5″ taller.

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

PrecisionRifleBlog.com A DATA-DRIVEN Approach to Precision Rifles, Optics & Gear

I’m curious, why did you angle the top where the press mounts?

Good question. First, it isn’t critical to angle it … just a personal preference for two reasons: 1) the press being slightly angled allows you to mount it a little lower while still providing necessary clearance for the ram with fully extended. 2) When using the press on a workbench height surface, I often find myself crouching to watch as I lower the handle on the press. The angled view is much better. You have a lot more visibility as you are operating the press. But, like I said … Ultimately it is personal preference. If you decide to keep it flat on top, you will likely need to raise the press-mount platform slightly to ensure you have adequate clearance (what I was talking about in #1). You could probably just extend the sides by an inch or so.

The cutout plan sheet is missing “back piece”. It shows the base, the two sides, and the top but not the back. May we assume this 7″ wide piece is gotten from whatever’s left over?

You are exactly right. Thanks for pointing that out. That was just an oversight on my part and I will get the cut-out drawing updated to include that. For now, you can look at the first diagram in the post, and it calls out the dimensions for that back piece. It is 7″ wide. Thanks again, and sorry for the inconvenience.

I’ve been looking at quite a few of these “Sinclair” copies and portable benches that are basically open-front boxes and have come to the conclusion that they were all designed around the builder’s own reloading press.

Would highly recommend that if anyone’s considering making a table-top portable bench that you make a cardboard mock-up first to ensure full ram and handle clearance! Ram drop and handle arm swing dimensions vary widely from press to press.

As it says in the very first sentence of this post, this portable reloading press stand was designed to work for either a full-size RCBS Rockchucker Press or smaller RCBS Partner Press. If you are using a different press, I agree that you should do some measurements first to make sure you will have adequate clearance. I don’t personally own every press, so I can’t test that for you. And unfortunately, the reloading press manufacturers don’t publish all of the dimensions you need to determine if there is adequate clearance. I had to measure for those dimensions myself for the RCBS presses, and you can find those measurements in this post: http://precisionrifle.wordpress.com/2012/07/17/rcbs-rock-chucker-press-mounting-template-dimensions/. If your press requires more clearance to allow a full ram stroke, then just add the necessary height to both sides, and you should be set.

This article was reference in a Sniper’s Hide post, with a couple good tips for adjustments that need to be made if you are using a press other than an RCBS Rockchucker (like a Lee press).

http://forum.snipershide.com/snipers-hide-reloading/190133-new-reloading-setup.html

I saw this design and was very excited by it. Got the wood, cut everything out, but then when i put it together, despite predrilling my holes, the sides split. Just wondering if you had similar experiences and if you can recommend anything different?

Sorry, Katie. I didn’t have that experience, and it’s the first I’ve heard of it. I know several who’ve used these same plans with success, so I might have to chalk it up to bad wood. What type of wood were you using?

Oak stair tread. I went to a different lowes today and picked up another one. Going to assemble it differently this time around. It is a GREAT design though. Being a military wife, I needed something portable and steady and this definitely fits the bill.

Well, Katie. I hope the 2nd piece of wood works for you. Please let me know. You were definitely on the right track pre-drilling the holes, so it sounds like you know what you’re doing. I work with wood a lot, and have even taken some classes from Marc Adams School of Woodworking. I’ve learned “wood will do what wood wants to do,” and two pieces may behave very differently even if they look similar. I feel like true 1″ oak lumber should be able to withstand the typical pressure of a press, especially with this over-engineered design. There aren’t a lot of unsupported spans. But please give me an update when you get the 2nd one built.

Thanks,

Cal

I nailed it! This thing is a solid beast! I wish there was a way to post a picture. I took it to the next level and stained it as well. I spent 30 minutes picking out this board and it was worth every minute. I used the next size up drill bit for my holes and used the drill press when I was able. I excessively clamped the pieces when putting everything together as well. Glue and screws did the job.

Again, EXCELLENT design. I could not be happier.

Awesome, Katie! Glad to hear your happy with the end result. I still use mine a lot.

Thanks,

Cal

Regarding the side holes for clamping it to the work bench, how exactly does that work if I’m using this on a large workbench top? My clamps would have to be exceptionally deep, right?

In my experience, you just need to clamp one side of it. In fact, if you’re just seating … it’s heavy enough that you don’t need to clamp it. I put rubber non-slip feet on the bottom, and it stays put. But when I’m sizing I will clamp down the side or the front of it … or both, if the cases are stubborn. You can place it on a corner of your bench, clamp one side and another clamp on the opposite front corner. Having side holes, just allows you to do that on either side.

Thanks,

Cal

Well the problem is that I’m working on an inside corner of a large workshop counter top with drawers so I’m really limited to how I can clamp things down.

Ah, you could always bolt it down … but that kind of defeats the purpose, at least some. Honestly, you might not need it clamped down. If yours ends up as heavy as mind, just having a hand on the front will keep it from moving when you’re resizing.

I would try it out on mine for you, but I’m out of town for a few days and honestly won’t be home but a couple nights between now and SHOT Show in late January.

The other portable press setup I’ve seen is simply a press bolted to a large, heavy I-beam. The I-beam wasn’t bolted to anything, so it was still portable … it was just super-heavy.

Wish I could be more help!

Cal

I built a similar stand 40 years ago from a plan in the American Rifleman. It was made from a cutout from a kitchen sink. The only adaption I made was to assure that my lever would clear the table and I put rubber feet on the bottom. It was used on a dining room table and made .224 bullets out of .22 RF cases.

Norm

Thanks for sharing, Norm. That certainly sounds like it would work, and it’s repurposing something that was likely headed to the dumpster otherwise. Did you need to hold it down with clamps or was it heavy enough to not lift up when you resized brass?

Thanks,

Cal

It did not move when full length resizing or when swaging the rimfire cases or the cores. There were rubber feet on the bottom and it was used on the dining room table.

Cool! Thanks.

Cal,

I haven’t built one yet, but it looks great, however, when it is not being used I would like to store it in the same storage tote as the press. So, I am thinking rather than use the Simpson Strong Ties, to use nuts, bolts & washers to attach the sides to the base just as you did the top. This change should allow me to totally dissemble it for storage in the tote. I will attach rubber feet to the base, so I will have to make sure they extend past the bolt head and washer underneath the base.

That sounds like a clever idea to me. You could probably do that in a way that doesn’t have any give in it. Let me know how it turns out!

Thanks,

Cal

Hi Cal,

Great plans! I’m going to make this for my Lyman Crusher, which seems to have a slightly smaller depth than your RCBS, so the existing dimensions should work just fine.

I do have a couple of questions:

-Did you glue and screw the top and base to the sides in addition to the angle brackets and Strong Ties? I’m not sure if this is needed or not.

-In the cut diagram, it seems like turning the top and back pieces 90-degrees so that the grain runs lengthwise would strengthen them, especially the top, which takes most of the strain and twisting motion. What do you think?

Thanks!

Hey, Dan. I’m glad you found these helpful. I didn’t glue the top down. It’s simply attached with the strong ties. Those are probably 1000x stronger than you actually need, so it’s already a bit overkill. I’m an engineer … it’s hard for guys like me to not over-engineer stuff! You certainly might be right about the strength of the grain of wood. That sounds right to me. Having said that, I haven’t experienced any issues and I’ve used this setup a lot. It’s really handy! Once again, I think the 1″ oak is much, much more than you actually need to support the pressure and torque you’re exerting on the sides. I like the angle because it feels more ergonomic for how I use it (on top of a standard height bench), but it’d be a simple mod to straighten that out. If you planned to use it on a taller bench, that actually might be ideal. Let me know what you try. I’d love for others that come along to see what other guys built and what they think about it. I’m hoping this can be a place where people share their own builds like that.

Thanks,

Cal